Preciznost i točnost u obradi metala

Postizanje uskih tolerancija s preciznim sečenjem vlaknovim laserom

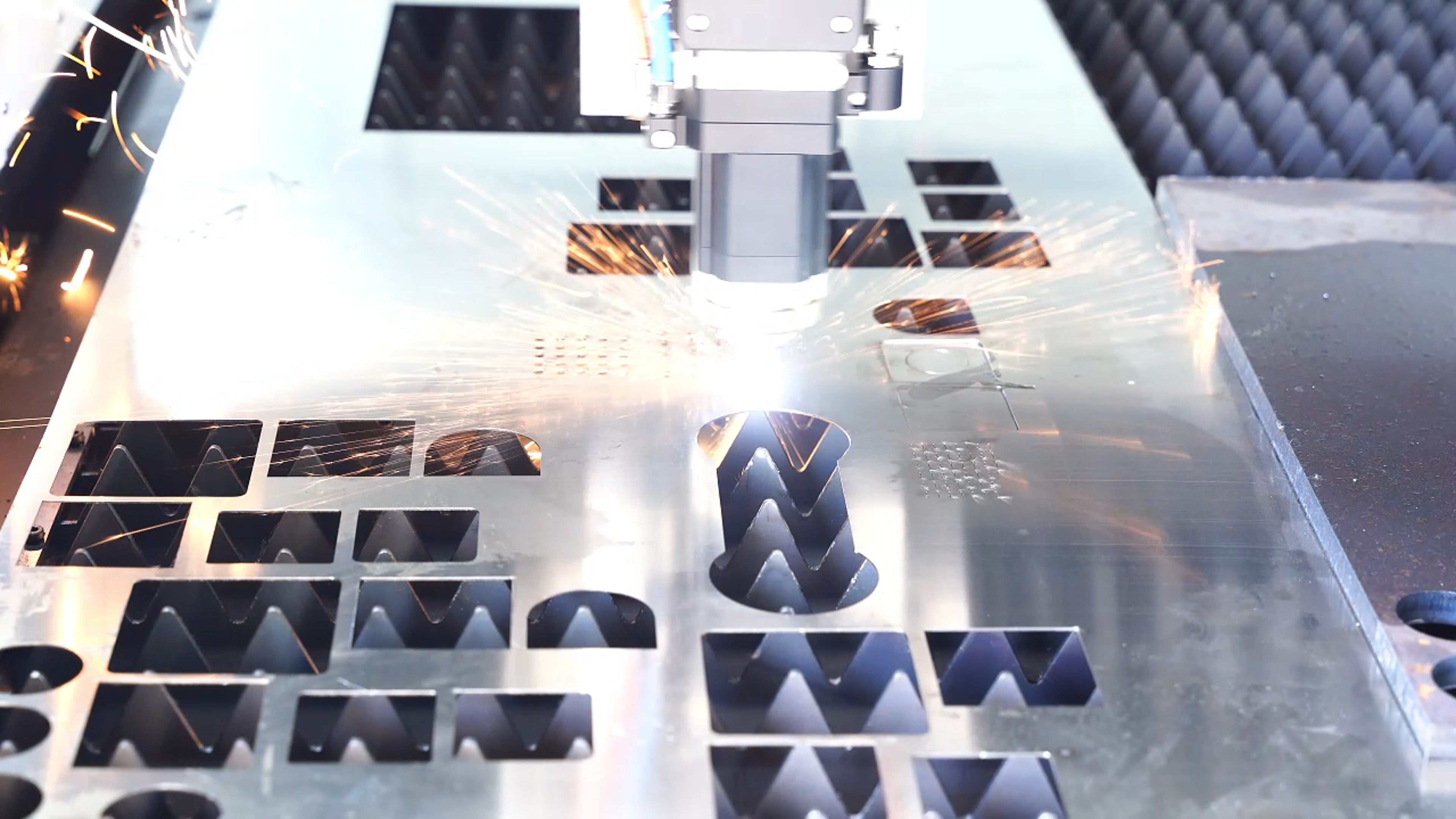

Strojevi za rezanje vlaknastim laserima osiguravaju izvanrednu preciznost, što ih čini idealnima za poslove koji zahtijevaju vrlo uske tolerancije, često čak i manje od plus minus 0,01 mm. Što daje ovim strojevima prednost? Napredni optički sustavi u kombinaciji s izvrsnom kvalitetom snopa zadržavaju laserski snop izuzetno usmjerenim na materijal koji se reže. Takva preciznost omogućuje stroju da točno prereže različite materijale bez odstupanja. Budući da vlaknasti laseri tako precizno režu, proizvođači često ne moraju ulagati vrijeme u naknadnu obradu nakon inicijalnog rezanja. To uštedi i vrijeme i novac u proizvodnim pogonima jer je potrebno obaviti manje dodatnih koraka. Za poduzeća koja rade u sektorima poput proizvodnje zrakoplova ili proizvodnje automobilskih dijelova, pristup tehnologiji vlaknastih lasera nije samo poželjan – praktički je obavezan, s obzirom na važnost preciznosti u tim kritičnim okolnostima.

Odlična kvaliteta rubova za smanjenu poslijedobnu obradu

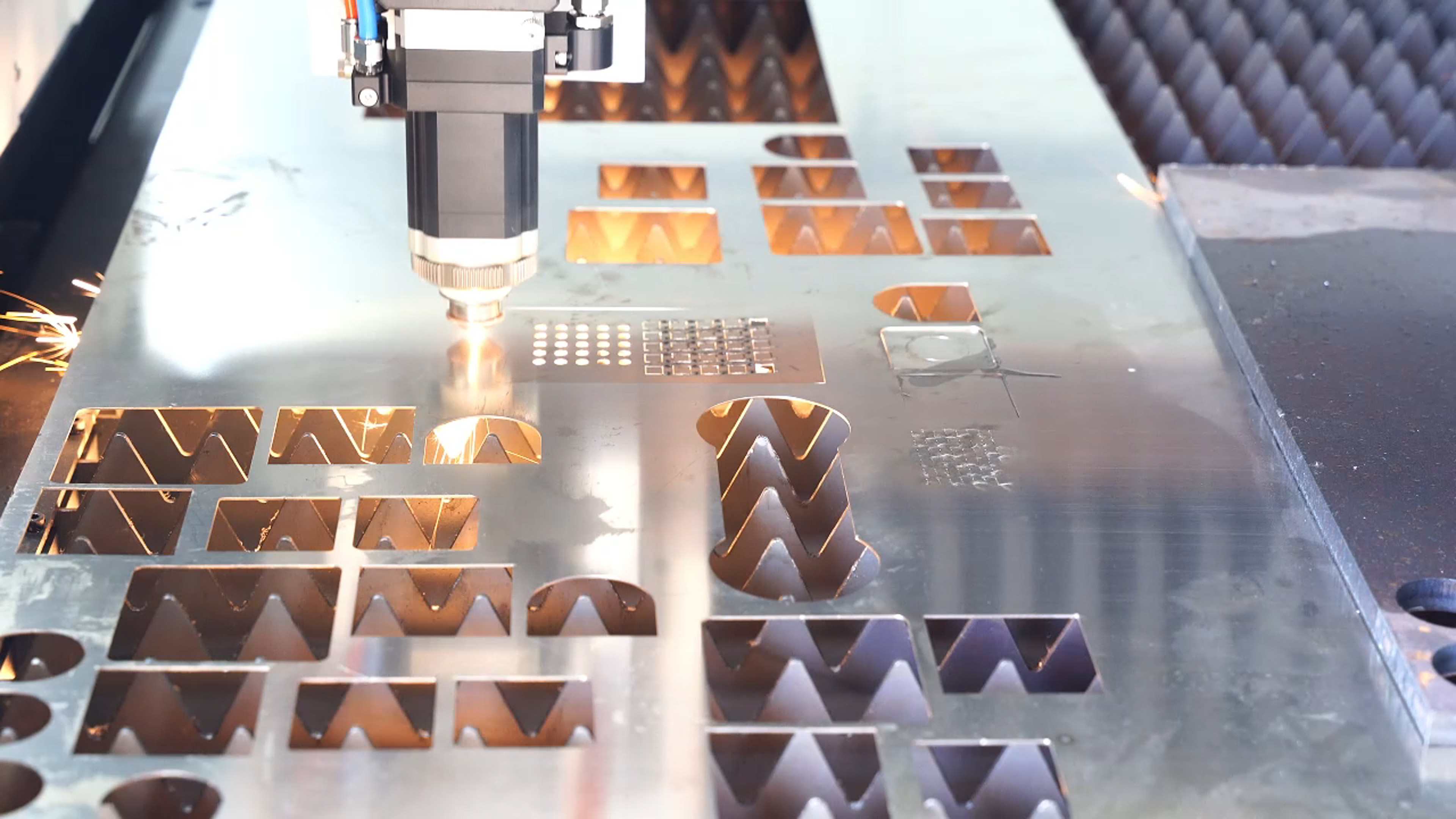

Rezanje vlaknastim laserima ističe se jer ostvaruje znatno bolju kvalitetu rubova u usporedbi s tradicionalnim metodama. Razlog? Ovaj sustav stvara manje područje utjecaja topline tijekom rada, pa su rezovi čistiji i s daleko manje nedostataka. Ovo je osobito važno za radionice koje vole provoditi manje vremena na dosadnim završnim poslovima poput brušenja grubih mjesta ili uklanjanja oštrih rubova s dijelova. Istraživanja u industriji pokazuju da kada tvrtke pređu na vlaknaste lasere, često smanje te dodatne korake za oko 40%. To znači stvarne uštede u vremenu i novcu tijekom proizvodnje. Za radionice koje se bave velikim obujmom dijelova, ovakva učinkovitost čini veliku razliku u ispunjavanju rokova i držanju troškova pod kontrolom.

Omogućavanje složenih geometrija i detaljnih dizajna

Laserskim rezacima s vlaknima obrađuju složene oblike i detaljne uzorke koje mnoge industrije zahtijevaju, posebno zrakoplovstvo i automobilska industrija gdje preciznost ima najveću važnost. Ove mašine nude stvarnu fleksibilnost kada su u pitanju mogućnosti dizajna, omogućavajući inženjerima da eksperimentiraju s idejama koje bi inače napustili. Za kompanije koje rade na prototipovima ili ograničenim serijama proizvodnje, to znači bržu pripremu proizvoda nego ikada ranije — što ih održava ispred konkurencije na tržištu. Proizvođači koji prelaze na laserske uređaje s vlaknima uočavaju da mogu pristupiti projektima koji zahtijevaju jedinstvene specifikacije, a da ne kompromitiraju kvalitetu. Tehnologija omogućava vrlo male tolerancije čak i na složenim dijelovima, što omogućuje zadovoljenje zahtjevnih potreba kupaca, a da se istovremeno troškovi proizvodnje drže pod kontrolom.

Visokobrzinsko režanje za brze proizvodne cikluse

Laserskim rezacima s vlaknima ističu se jer vrlo brzo režu materijale, čime se skraćuje trajanje proizvodnje. Određeni modeli dosežu brzine rezanja do 60 metara u minuti, što čini ove strojeve izvrsnima za tvornice koje moraju proizvesti velike količine. Brže rezanje znači da se u istom vremenu proizvede više dijelova, pa cijela tvornica može proizvesti više proizvoda ukupno. Kraći ciklusi znače da tvornički uredaji mogu bolje preurediti tijek posla. Uredaji primjećuju da troše manje vremena čekajući između operacija, a radnici provode manje vremena nadzirajući strojeve budući da se sve odvija glatko. Ovakva učinkovitost na duži rok štedi novac, a istovremeno održava proizvodnju na najvišem nivou.

Integracija s CNC Laser Rezanjem Automatizacijom

Kada se laserska vlakna kombiniraju s CNC sustavima, to predstavlja pravu promjenu igre u današnjim proizvodnim procesima. Kombinacija stvara potpuno automatizirane radne procese koji neprekidno rade bez stalnog nadzora. Tvornice bilježe manje pogrešaka jer ljudi više ne ručno podešavaju postavke. Što to znači? Veću dosljednost rezultata između serija i ukupno bolju kvalitetu proizvoda. Prema nedavnim industrijskim izvještajima, tvrtke koje su usvojile automatizaciju CNC laserskog rezanja obično zabilježe skok produktivnosti od oko 30% ili više. Za proizvođače koji žele smanjiti troškove i poboljšati svoje financijske rezultate, investiranje u ovu vrstu tehnologije ima potpunog smisla. Priča više nije samo o tome da se drži korak s natjecateljima – mnoge proaktivne radionice već su ispred krivulje zahvaljujući ovim napretcima.

Istražite tehnologiju vlaknovitog laser reza

Smanjivanje potrošnje energije i operativnih troškova

Fiber laserski rezni strojevi ističu se uštedom u energiji, zbog čega su znatno jeftiniji za uporabu u odnosu na tradicionalne metode rezanja. Metalne radionice priopćuju da su smanjile troškove struje za oko pola nakon prelaska na ove sustave, što se tijekom vremena pretvara u stvarnu uštedu novca. Niža potrošnja energije znači ekološkiju proizvodnju, a istovremeno održava dobar financijski rezultat. Radionice koje pređu na fiber lasersko rezanje često se nađu ispred konkurencije jer imaju niže troškove rada i brže obavljaju poslove. Za proizvođače koji rade s tankim maržama, ovakva učinkovitost čini razliku u održavanju dobitnosti tijekom teških tržišnih uvjeta.

Minimiziranje otpadnih materijala putem preciznog raspoređivanja

Kada proizvođači kombiniraju softver za precizno smještanje s laserskim rezalnim sustavima, postižu nešto izuzetno učinkovito u pogledu materijala. Softver u osnovi smješta sve te izrezane oblike na metalne ploče na način da gotovo ne ostaje nepotrebni prostor. U mnogim slučajevima, to znači uštedu oko 20% sirovina. Takvo smanjenje otpadaka znači stvarnu uštedu na proizvodnim troškovima i bolje konačne rezultate na kraju mjeseca. S ekološkog stajališta, ovi sustavi smanjuju gomile otpadnog materijala u skladištima i tvornicama. Metalni obrtnici koji uvedu ovu tehnologiju istovremeno smanjuju troškove i svoj ugljični otisak. Za radionice koje žele ostati konkurentne i istovremeno odgovorno djelovati, investiranje u kvalitetan softver za smještanje ima smisla s više aspekata.

Možnosti presjeka za metalne ploče i debele ploče

Fiber laserski rezni strojevi donose stvarnu fleksibilnost, jer se dobro pokazuju u poslovima od delikatnih limova pa sve do rezanja prilično debelih ploča. Oni mogu raditi s materijalima debljine od otprilike 0,1 milimetra sve do preko 25 mm, što ih čini prilično prilagodljivima za većinu potreba na radnoj podlozi. Građevinske tvrtke, proizvođači automobila i tvrtke koje proizvode industrijske dijelove sve su prihvatile ove strojeve jer omogućuju brži rad bez žrtvovanja kvalitete. Ono što zaista ističe jest kako ovi sustavi jednako učinkovito rade u malim radionicama kao i u ogromnim proizvodnim pogonima, što objašnjava zašto ih različite tvrtke redovno biraju već godinama.

Primjene u automobilnoj i aerokosmičkoj proizvodnji

Fiber laserski uređaji za rezanje praktički su preuzeli mnoge radionice u proizvodnji automobila i zrakoplova jer daju izuzetne rezultate pri izvođenju preciznih rezova i brzom ciklusu proizvodnje. Za proizvođače automobila, ovi laseri omogućuju masovnu proizvodnju dijelova koji se savršeno uklapaju svaki put. Zamislite blok motora ili složene ploče karoserije gdje čak i najmanje greške mogu izazvati velike probleme u budućnosti. Stručnjaci iz automobilske industrije vole koliko brzo ove mašine mogu obrađivati različite debljine metala bez narušavanja kvalitete. U zrakoplovnoj industriji priča je slična, ali još zahtjevnija. Ovi laseri prerezuju titanijum legure i druge izuzetno jake materijale s kojima bi se standardna oprema mučila. Stroga tolerancija potrebna za komponente aviona znači da proizvođači ne mogu priuštiti ništa manje od apsolutne savršenosti. Zbog toga se u obje industrije sve više udomaćuju fiber laseri na radnim mjestima tamo gdje se preciznost susreće s pritiskom.

Prilagođavanje različitim metalima: od nerustingujućeg čelika do aluminija

Vlaknasti laseri zaista imaju prednost kod rezanja svih vrsta metala uključujući nehrđajući čelik, aluminij, mjed i čak bakar. Proizvođači to vole jer mogu proširiti asortiman proizvoda bez potrebe za kupnjom nekoliko različitih strojeva za rezanje za svaki materijal. Tvrtke imaju prednost što mogu brzo reagirati na bilo kakve potrebe kupaca. Svestranost znači da tvornice mogu nuditi više proizvoda i dalje zadržavajući niske troškove jer nema potrebe za dodatnom opremom koja stoji neiskorištena. U današnjem brzoprotečnom proizvodnom svijetu, posjedovanje laserskih sustava koji mogu obraditi različite materijale daje tvrtkama stvarnu prednost u odnosu na konkurenciju koja je zarobljena zastarjelom ili ograničenom tehnologijom.

Trendovi prihvaćanja u savremenim radionicama za oblikovanje

Tehnologija laserskih vlakana posljednjih godina stvarno je uzletjela u radionicama za obradu metala, s oko 60 posto radionica koje ju sada redovno koriste u svakodnevnom radu. Brojke pričaju priču o proizvođačima koji brzo prelaze na visoke tehnologije koje povećavaju učinkovitost, uz održavanje strogih tolerancija i ubrzavanje vremena proizvodnje. Radionice širom zemlje polako počinju razumijevati razlog uzbuđenja, što objašnjava zašto analitičari tržišta očekuju da će prodaja laserskih rezbarica s vlaknima porasti otprilike 12% godišnje u narednim godinama. Ono što doživljavamo nije samo postepeni napredak. Ovaj tehnološki skok transformira način na koji se danas obrađuje metal i priprema tlo za još veće inovacije u budućnosti, dok se tvrtke prilagođavaju kako bi ostale konkurentne.

Buduće inovacije u tehnologiji strojeva za lasersku rezbu

Gledajući unaprijed u tehnologiji laserskog rezanja, većina stručnjaka vjeruje da će sljedeći veliki val biti usmjeren na brža rezanja i bolje automatske značajke. Već se vidi nekoliko uzbuđujućih pomaka prema pametnijim strojevima. Umjetna inteligencija počinje igrati veću ulogu u ovom području, omogućavajući opremi da se sama fino prilagodi tijekom rada, bez stalnog operatorovog utjecaja. U isto vrijeme, kontrolni sustavi postaju pametniji i osjetljiviji, što znači kraće vrijeme postavljanja i manje otpadnog materijala ukupno. Za proizvođače koji rade s metalima ili plastikama, ovakav napredak izravno se prevodi u stvarne štednje i dobiti u proizvodnji. Metalne radionice s kojima sam nedavno razgovarao sve spominju želju za nadogradnjom svojih sustava uskoro, uglavnom zato što su natjecatelji koji su prvi usvojili ove nove tehnologije stekli značajne prednosti na tržištu.

Sadržaj

-

Preciznost i točnost u obradi metala

- Postizanje uskih tolerancija s preciznim sečenjem vlaknovim laserom

- Odlična kvaliteta rubova za smanjenu poslijedobnu obradu

- Omogućavanje složenih geometrija i detaljnih dizajna

- Visokobrzinsko režanje za brze proizvodne cikluse

- Integracija s CNC Laser Rezanjem Automatizacijom

- Smanjivanje potrošnje energije i operativnih troškova

- Minimiziranje otpadnih materijala putem preciznog raspoređivanja

- Možnosti presjeka za metalne ploče i debele ploče

- Primjene u automobilnoj i aerokosmičkoj proizvodnji

- Prilagođavanje različitim metalima: od nerustingujućeg čelika do aluminija

- Trendovi prihvaćanja u savremenim radionicama za oblikovanje

- Buduće inovacije u tehnologiji strojeva za lasersku rezbu