Years of

Experience

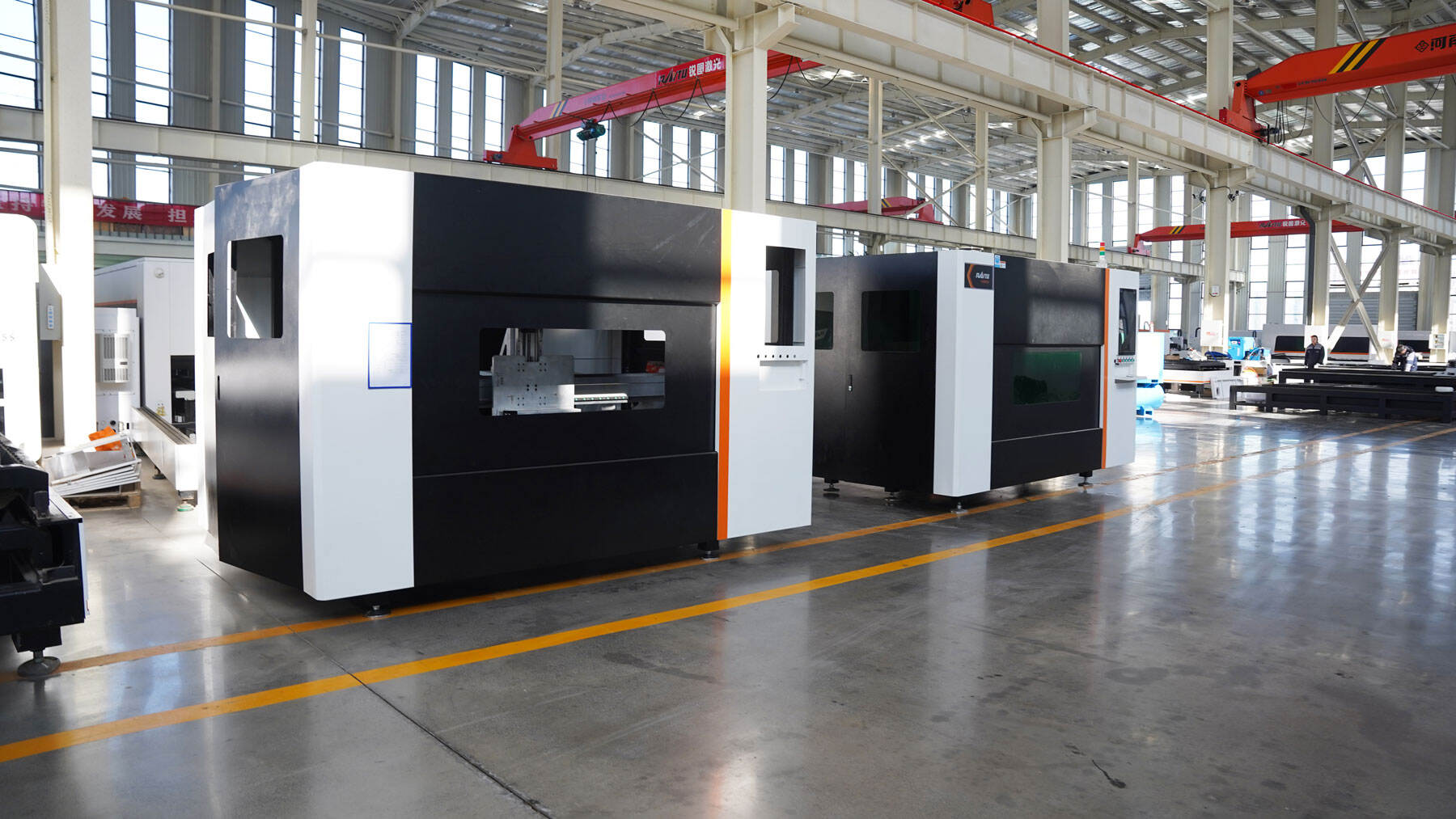

RT Laser is a nationally recognized high-tech enterprise specializing in the research, development, production, and sales of laser equipment. Our core products include fiber laser cutting machines, handheld laser welding machines, and bending machines.

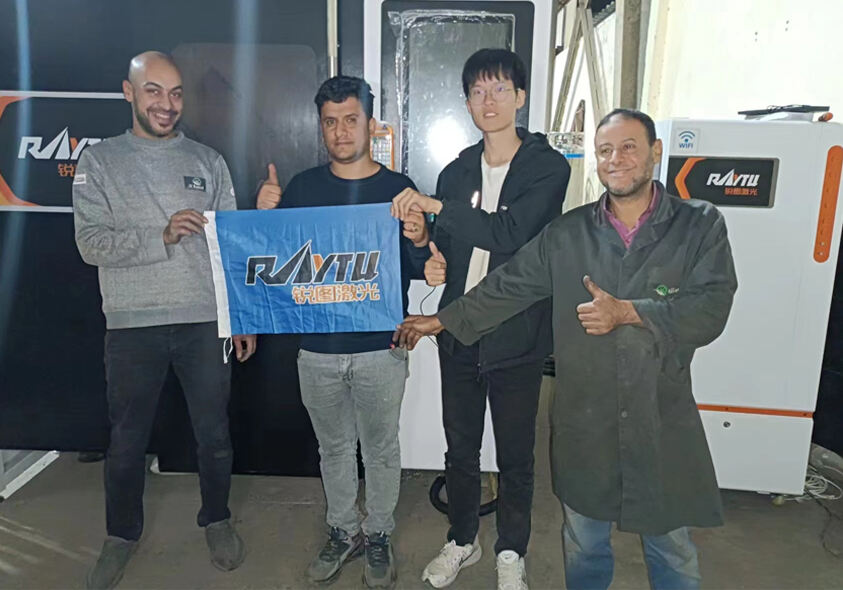

All our machines are certified by European CE, US FDA, and ISO9001 standards, ensuring top-notch quality and compliance. With a global presence, our machines have been exported to over 100 countries, including the United States, Russia, Turkey, and Australia.

We are committed to leveraging the most advanced scientific and technological innovations to deliver the best solutions for the machinery manufacturing industry.

Localized Support with Offices in 6+ Countries

80+ Experts in Mechanical R&D

Empowering 3,500+ Customers Worldwide

State-of-the-Art 25,000㎡ Factory

Laser cutting, as a new cutting technology, has revitalized the metal processing industry. Due to its high efficiency, precision, and environmentally friendly process, it is now widely used in many metal processing sectors.

RT Laser Committed to Quality Machines and Service, Innovating to Lead the Industry.

Each machine undergoes 3 rounds of testing before leaving the factory and runs perfectly for 100 h

Online response within 1 h to help solve problems. For major problems, door-to-door service within 36 h

Free cutting/welding/bending metal samples for customers before purchasing ; free training after purchasing

Regular size machines shipped in 10 days,customized machines shipped within 25 days

We will frequently update exhibition news and major company events, so stay tuned.

Stop downtime before it happens. A comprehensive daily, weekly, and monthly maintenance checklist for fiber laser cutting machines. Keep your Raytu laser running at peak performance.

Feb, 09, 2026

Maximize the lifespan of your CNC fiber laser cutter by mastering consumable management. This guide covers the critical roles of protective lenses, ceramic rings, nozzles, and auxiliary gases. Learn how to choose high-quality parts, prevent lens damage, and maintain stable cutting quality. Essential reading for operators looking to reduce downtime and optimize operational costs with Raytu Laser.

Jan, 31, 2026

A comprehensive guide to laser cutting operating costs. Learn how assist gases like Oxygen and Nitrogen impact your budget and the differences between Fiber and CO2 gas requirements.

Jan, 23, 2026

Stop wasting profits on high energy bills. Discover how fiber laser technology offers 30-50% efficiency vs 10% for CO2. Compare real-world power consumption, daily electricity costs, and see why the Raytu 3015H is the cost-effective choice for your factory.

Jan, 19, 2026