A comprehensive guide to laser cutting operating costs. Learn how assist gases like Oxygen and Nitrogen impact your budget and the differences between Fiber and CO2 gas requirements.

Read More

Stop wasting profits on high energy bills. Discover how fiber laser technology offers 30-50% efficiency vs 10% for CO2. Compare real-world power consumption, daily electricity costs, and see why the Raytu 3015H is the cost-effective choice for your factory.

Read More

Unlock the precision of laser cleaning by mastering process parameters. Learn how wavelength, pulse width (ns, ps, fs), fluence (J/cm²), and repetition rate control ablation and ensure selective contaminant removal with zero substrate damage. Essential reading for industrial users.

Read More

Discover the versatility of laser cleaning technology. Learn what materials and surfaces—from corroded steel on offshore rigs and aluminum oxide on aerospace parts to historic sandstone and PCB conformal coatings—can be safely and precisely cleaned using non-contact lasers. See why industries choose laser ablation for superior precision and environmental safety.

Read More

Laser cleaning is suitable for a wide range of materials, including metals, stone, ceramics, polymers, and organic surfaces. This article explains how different materials respond to laser cleaning and which contaminants can be safely removed without damaging the substrate.

Read More

Laser cleanability depends on multiple factors, including optical absorptivity, thermal conductivity, coating thickness, adhesion strength, and surface geometry. This article explains the key variables that influence whether a material or surface can be safely and effectively cleaned using laser technology.

Read More

Laser cleaning offers a safer, cleaner, and more precise alternative to abrasive blasting, chemical stripping, and dry-ice blasting. This article compares traditional methods and highlights the advantages of laser cleaning, including non-contact operation, selective removal, minimal waste, and superior environmental performance.

Read More

Laser cleaning machines can remove rust, paint, oxides, grease, and surface residues from various metals, alloys, and delicate materials. This article explains the principles of laser cleaning, including photo-thermal and photo-mechanical mechanisms, key laser parameters, and how different contaminants interact with substrates. Learn how to safely and efficiently apply laser cleaning across industrial applications.

Read More

Laser and plasma cutting both involve high heat and energy, making safety and maintenance essential. Learn how to prevent optical, electrical, and fire hazards, manage fumes, and extend equipment service life. Discover which cutting method offers lower maintenance and greater long-term reliability.

Read More

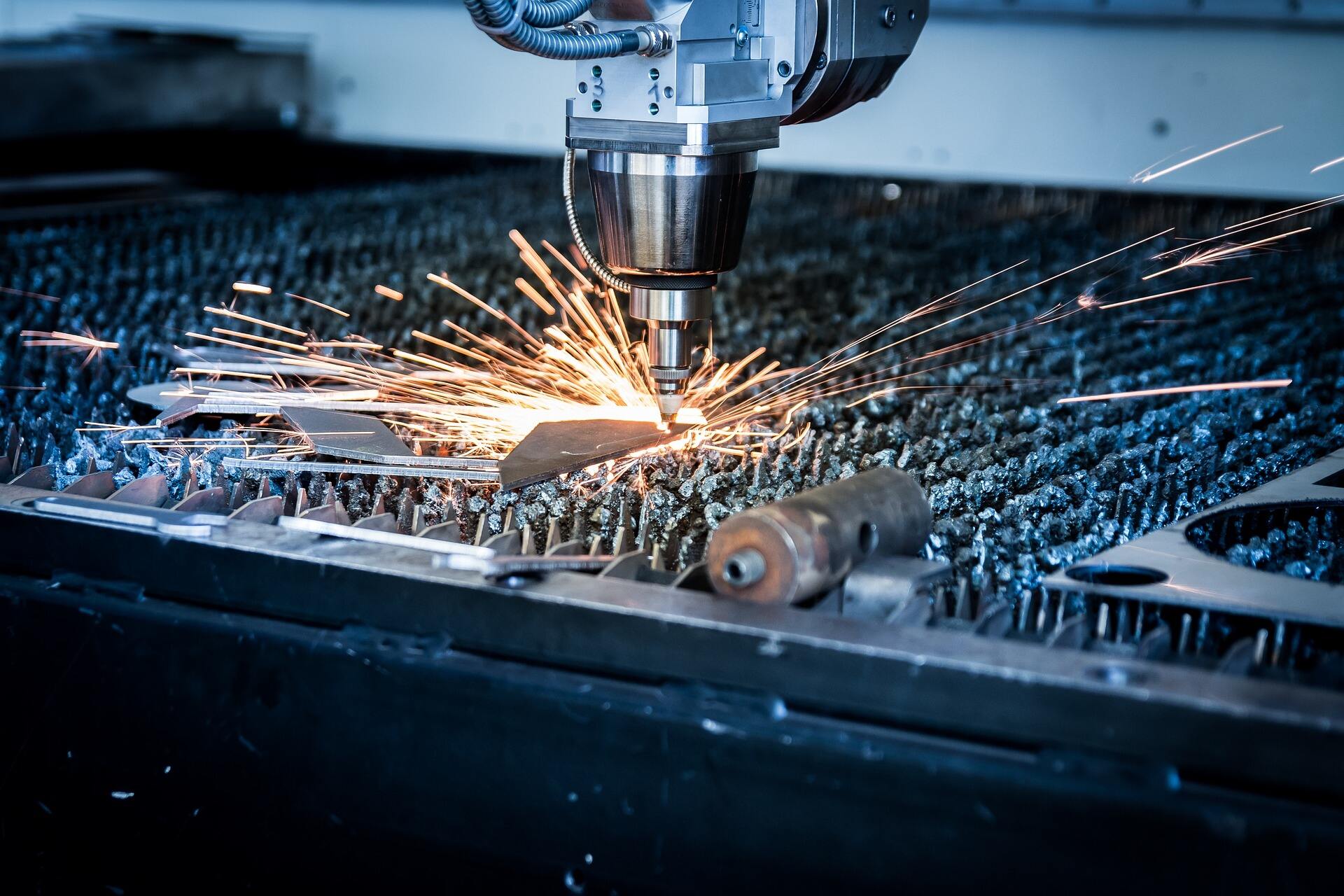

Laser cutting and plasma cutting differ in speed, productivity, and total cost of ownership. Laser cutting delivers high precision and efficiency for thin materials, while plasma cutting excels in high-speed cutting of thick metals at a lower upfront cost. Learn which process best fits your production goals and budget.

Read More

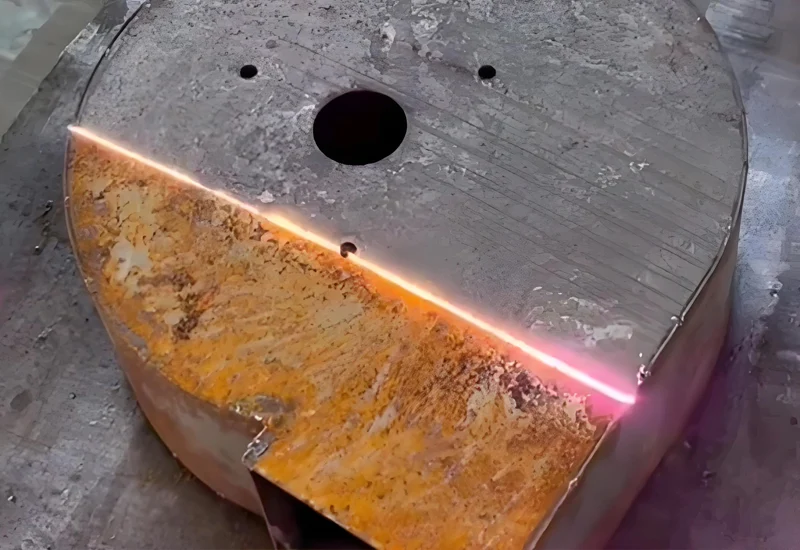

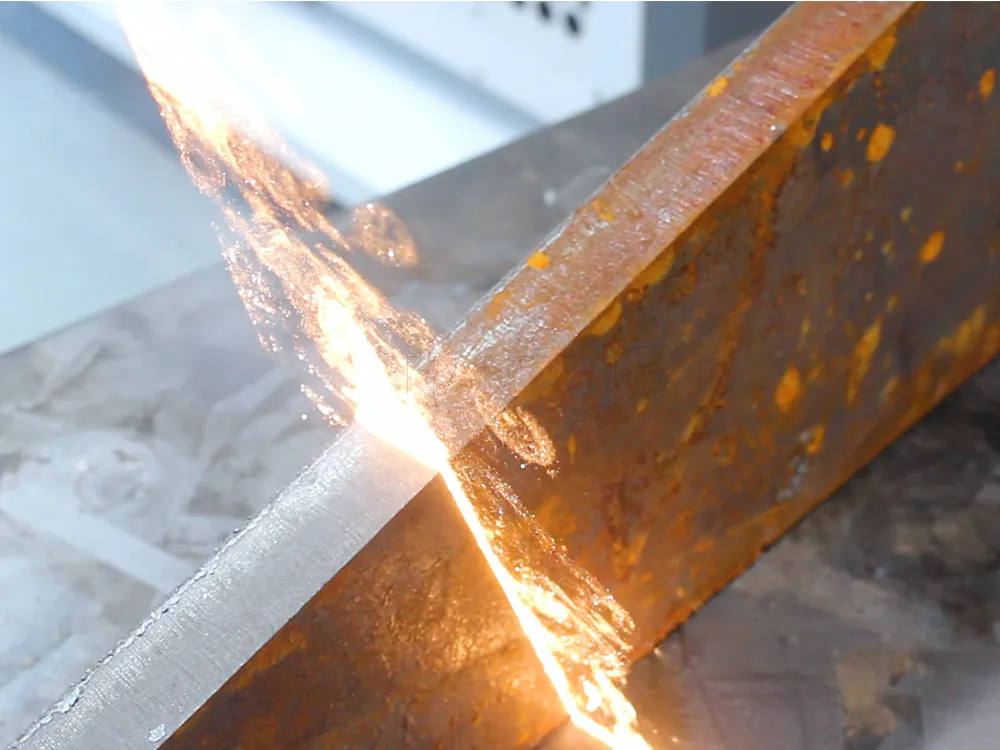

Explore how laser and plasma cutting perform across different materials and thicknesses. Compare cutting precision, kerf width, and edge quality to choose the best method for your metal fabrication needs.

Read More

Compare laser cutting and plasma cutting technologies — explore their working principles, advantages, equipment, and best applications for metal fabrication.

Read More Hot News

Hot News