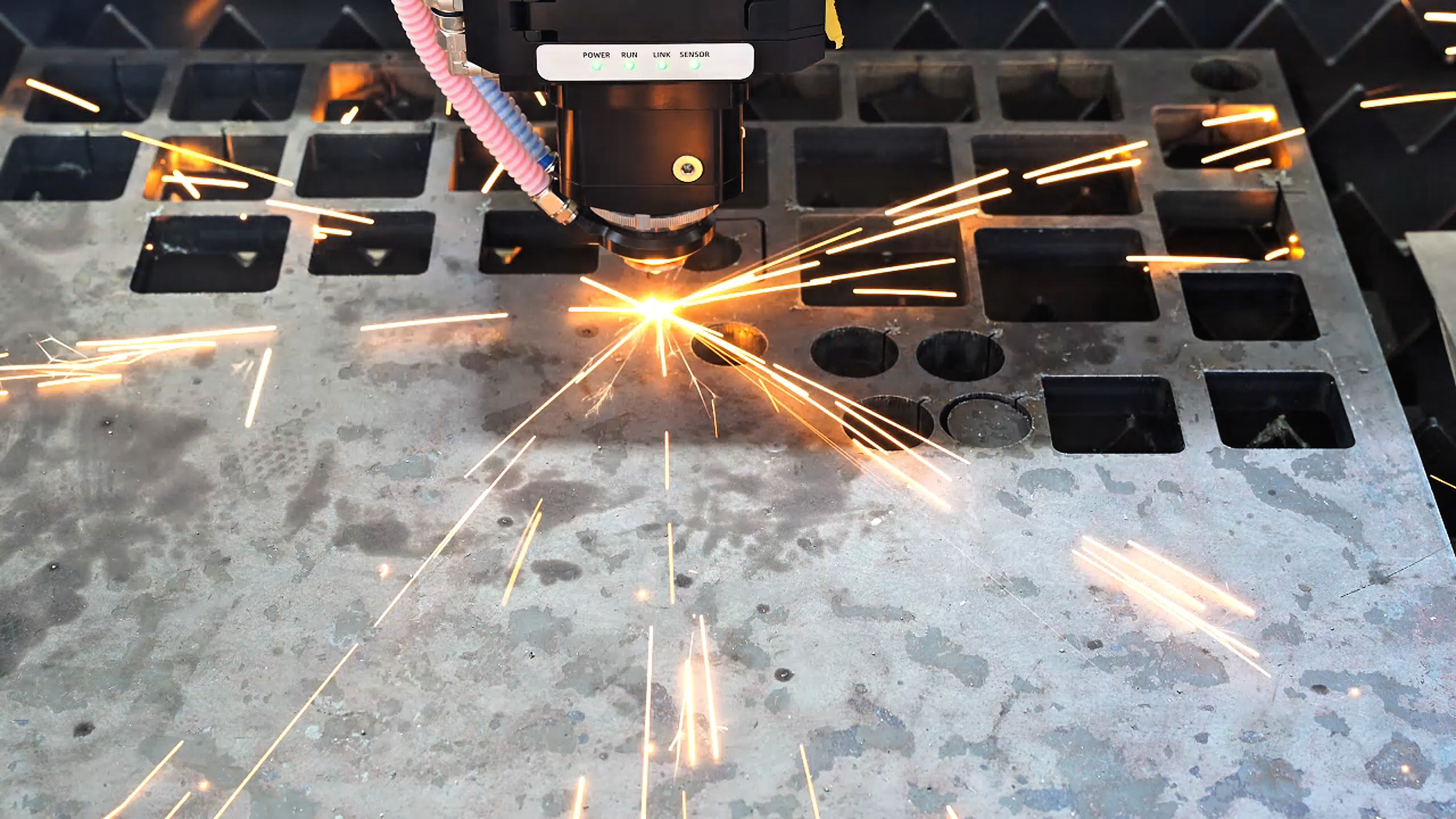

When evaluating the real operating cost of a laser cutting machine, electricity is often the "hidden profit killer." For a factory running double shifts, power consumption isn’t just a utility bill—it’s a major factor in your price-per-part competitiveness.

While both fiber and CO2 technologies are industry staples, their energy profiles are worlds apart. Here is a practical breakdown of how fiber laser efficiency translates into bottom-line savings.

The fundamental difference lies in Wall-Plug Efficiency—the percentage of electrical power that actually turns into a cutting beam rather than wasted heat.

Fiber Lasers: These systems are incredibly efficient, converting 30% to 50% of input power into a laser beam.

CO2 Lasers: Older gas-based technology is notoriously inefficient, usually converting only 10% to 15% of the power it draws.

In a real factory setting, this means for every $100 you spend on power, a fiber laser uses $40 to cut metal, while a CO2 laser might waste $90 just generating heat that your chiller then has to work even harder to remove.

Let’s look at the total system draw, which includes the resonator, CNC controller, servo motors, and the exhaust system.

Typically, a fiber laser setup draws between 6kW and 12kW during active cutting. Because the solid-state architecture is compact, the cooling requirements are minimal.

A comparable CO2 machine is a power-hungry beast. Between the high-voltage power supplies, the gas circulation turbines, and the massive chillers required to cool the inefficient resonator, the total draw often spikes to 20kW or even 30kW.

To make this practical, let’s calculate the cost based on an average industrial rate of $0.10 per kWh for a standard 8-hour shift (approx. 22 days/month).

| Machine Type | Typical Power Draw | Daily Cost (8hrs) | Monthly Cost |

| Fiber Laser | 8 kW | $6.40 | $140.80 |

| CO2 Laser | 22 kW | $17.60 | $387.20 |

The Result: Switching to fiber technology can save you over $3,000 per year on a single-shift operation. For factories running 24/7, those savings often pay for the machine's financing costs alone.

One detail many buyers overlook is the HVAC and Cooling load. Because CO2 lasers generate massive amounts of waste heat, they require high-tonnage chillers. This doesn't just increase your power bill; it also increases the ambient temperature of your workshop, potentially requiring more air conditioning and more frequent maintenance on sensitive electronic components.

While CO2 lasers still have a niche in specific non-metal or thick acrylic applications, the energy efficiency of a fiber laser like the Raytu 3015H makes it the clear winner for modern metal fabrication. You aren't just buying a faster cut; you are securing a lower overhead for the next decade.

Hot News

Hot News