Precision and Accuracy in Metal Fabrication

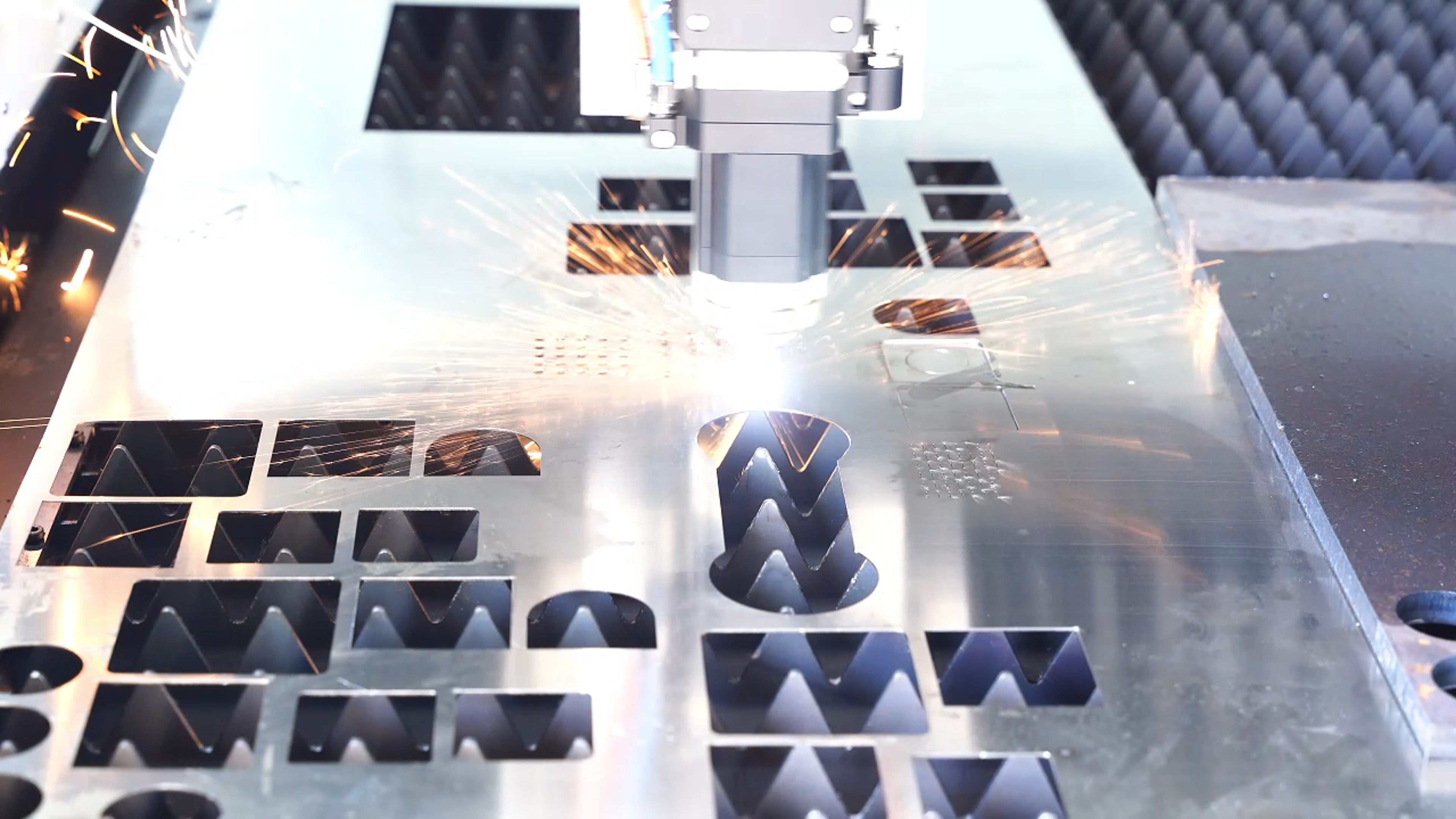

Achieving Tight Tolerances with Fiber Laser Cutting

Fiber laser cutting machines deliver amazing precision, which makes them ideal for jobs needing really tight tolerances sometimes as small as plus or minus 0.01 mm. What gives these machines their edge? Advanced optical systems combined with excellent beam quality keep the laser beam super focused on the material being cut. This focus allows the machine to slice through different materials accurately without wandering off track. Because fiber lasers cut so precisely, manufacturers usually don't have to spend time on post processing work after the initial cut. That saves both time and money in production shops since there are fewer additional steps required. For companies working in fields like aerospace manufacturing or car part production, getting access to fiber laser tech isn't just nice to have it's practically mandatory given how critical precision becomes in those high stakes environments.

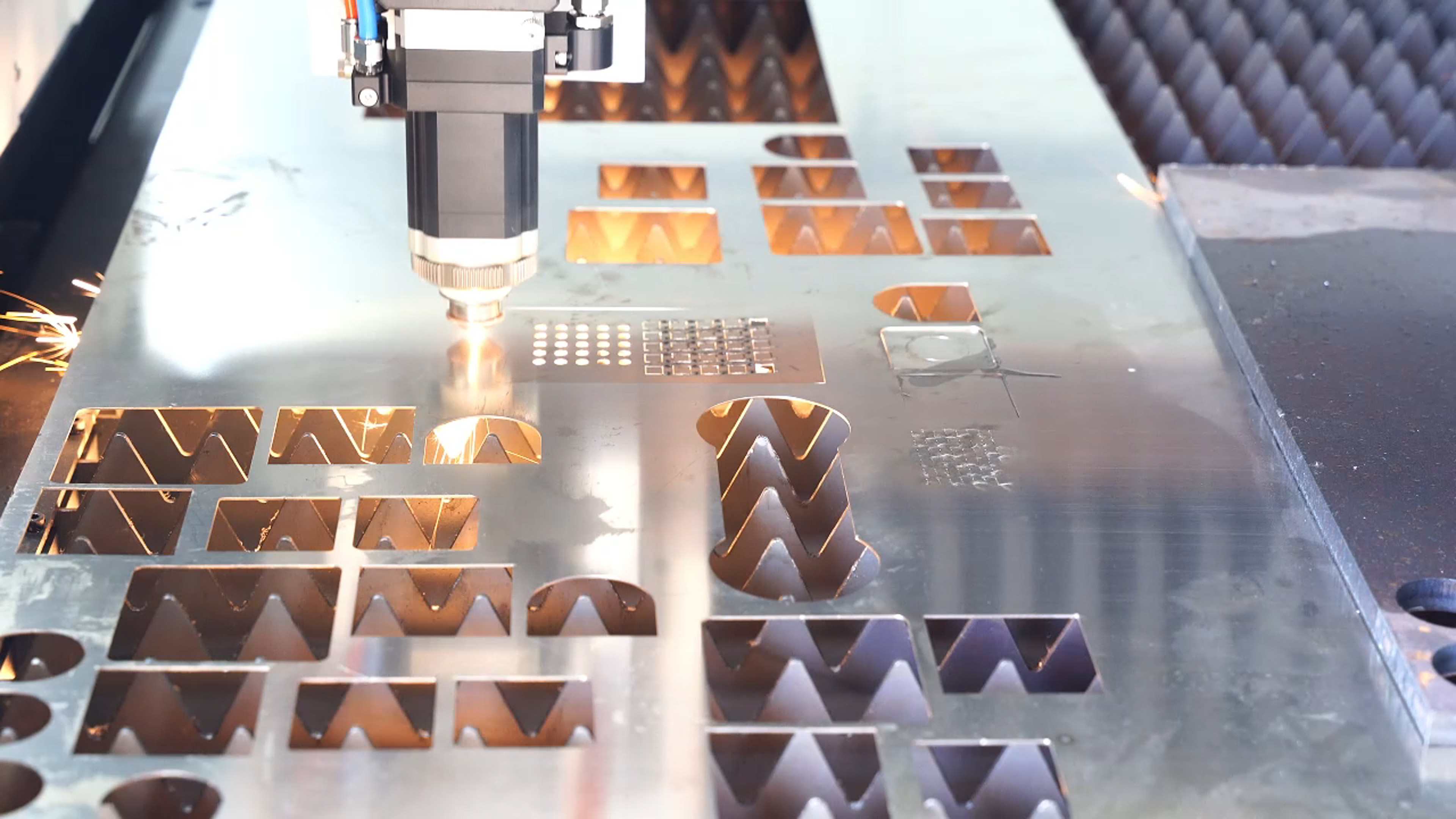

Superior Edge Quality for Reduced Post-Processing

Fiber laser cutting stands out because it creates much better edge quality than traditional methods. The reason? These systems create smaller heat affected areas during operation, so the cuts come out cleaner with far fewer flaws. Fabrication shops love this because they spend less time on those tedious finishing jobs like grinding away rough spots or removing burrs from parts. Industry research shows that when companies switch to fiber lasers, they often cut down on these extra steps by around 40%. That means real savings in both time and money across production runs. For metalworking shops handling large volumes of parts, this kind of efficiency makes all the difference in meeting deadlines while keeping overhead costs under control.

Enabling Complex Geometries and Intricate Designs

Fiber laser cutters handle complex shapes and detailed patterns that many industries need, especially aerospace and automotive sectors where precision matters most. These machines offer real flexibility when it comes to design possibilities, letting engineers experiment with ideas they might otherwise abandon. For companies working on prototypes or limited production runs, this means getting products ready faster than ever before something that keeps them ahead in competitive markets. Manufacturers who switch to fiber lasers find themselves able to tackle projects requiring unique specifications without sacrificing quality. The technology allows for tight tolerances even on complicated parts, making it possible to meet demanding customer requirements while still keeping costs under control during production cycles.

High-Speed Cutting for Rapid Production Cycles

Fiber laser cutters stand out because they cut materials really fast, cutting down on how long production takes. Some models actually reach speeds around 60 meters per minute, which makes these machines great for factories that need to produce large quantities. The faster cutting means more parts get made in the same amount of time, so the whole factory can crank out more product overall. Shorter cycles mean shops can rearrange their workflow better too. Shops find they waste less time waiting between operations, and workers spend less time monitoring the machines since everything moves along so smoothly. This kind of efficiency saves money in the long run while keeping production running at peak levels.

Integration with CNC Laser Cutting Automation

When fiber lasers get paired with CNC systems, it marks a real game changer for how things are made these days. The combination creates fully automated workflows that just keep running without constant supervision. Factories see fewer mistakes because humans aren't manually adjusting settings all the time. What does this mean? More consistent results across batches and better overall product quality. According to recent industry reports, companies that have adopted CNC laser cutting automation typically see their productivity jump by around 30% or more. For manufacturers looking to cut costs while improving their bottom line, investing in this kind of tech makes perfect sense. It's not just about keeping up with competitors anymore either many forward thinking shops are already ahead of the curve thanks to these advancements.

Explore Fiber Laser Cutting Technology

Reducing Energy Consumption and Operational Costs

Fiber laser cutters stand out when it comes to saving power, making them much cheaper to run than old school cutting techniques. Metal shops report cutting their electric bills by around half after switching to these systems, which adds up to real money saved over time. Lower power usage means greener operations while still keeping the bottom line healthy. Shops that make the switch to fiber lasers often find themselves ahead of competitors because they spend less on running costs and get things done faster. For manufacturers dealing with tight margins, this kind of efficiency makes all the difference in staying profitable during tough market conditions.

Minimizing Material Waste Through Precision Nesting

When manufacturers combine precision nesting software with fiber laser cutting systems, they get something pretty remarkable for material efficiency. The software basically arranges all those cut shapes on metal sheets in ways that leave almost no wasted space. We're talking about saving around 20% of raw materials in many cases. That kind of waste reduction means real money saved on production costs and better bottom line numbers at the end of the month. From an environmental standpoint, these systems cut down on scrap heaps in warehouses and factories. Metal fabricators who implement this technology see both their wallets and their carbon footprint shrink simultaneously. For shops looking to stay competitive while being responsible citizens, investing in good nesting software makes perfect sense on multiple fronts.

Cutting Capabilities for Sheet Metal and Thick Plates

Fiber laser cutters bring real flexibility to the table, working well for everything from delicate sheet metal jobs right up to cutting through fairly thick plates. They handle materials ranging from around 0.1 millimeters all the way to over 25mm thicknesses, which makes them pretty adaptable for most shop floor needs. Construction firms, car manufacturers, and companies making industrial parts have all jumped on board with these machines because they get things done faster without sacrificing quality. What really stands out is how these systems work just as effectively in small workshops as they do in massive production facilities, which explains why so many different businesses keep coming back to fiber lasers year after year.

Applications in Automotive and Aerospace Manufacturing

Fiber laser cutting machines have basically taken over many shops in automotive and aerospace manufacturing because they just work so well for precise cuts and fast production times. For car makers, these lasers let them churn out parts that fit together perfectly every time. Think about engine blocks or complicated body panels where even tiny mistakes can cause big problems down the line. The automotive guys love how quickly these machines can handle all sorts of metal thicknesses without compromising quality. Over in aerospace, the story is similar but even more demanding. These lasers slice through titanium alloys and other super strong materials that regular equipment would struggle with. The tight tolerances required for aircraft components mean manufacturers can't afford anything less than absolute perfection. That's why we see fiber lasers dominating shop floors across both industries wherever precision meets pressure.

Adapting to Diverse Metals: Stainless Steel to Aluminum

Fiber lasers really excel when it comes to cutting all sorts of metals including stainless steel, aluminum, brass and even copper. Manufacturers love this because they can expand what they produce without buying several different cutting machines for each material. Companies benefit from being able to respond quickly to whatever customers need next. The versatility means factories can offer more products while still keeping costs down since there's no need for extra equipment sitting around unused. In today's fast paced manufacturing world, having laser systems that handle various materials gives shops a real advantage over competitors stuck with outdated or limited technology.

Adoption Trends in Modern Fabrication Shops

Fiber laser tech has really taken off in fabrication shops lately, with around 60 percent now using it regularly in day-to-day work. The numbers tell a story of manufacturers moving fast toward high-tech solutions that boost efficiency while maintaining tight tolerances and speeding up production times. Shops across the country are starting to see what all the fuss is about, which explains why market analysts expect fiber laser cutter sales to climb by roughly 12% each year going forward. What we're witnessing isn't just incremental improvement either. This technological leap is transforming how metal gets processed today and setting the stage for even bigger innovations down the road as companies adapt to stay competitive.

Future Innovations in Laser Cutting Machine Technology

Looking ahead in laser cutting tech, most experts believe the next big wave will center around faster cuts and better automation features. Already seeing some exciting moves toward smarter machines too. Artificial intelligence is starting to play a bigger role here, letting equipment fine tune itself during operation without constant operator input. At the same time, control systems are getting smarter and more responsive, which means fewer setup times and less waste material overall. For manufacturers working with metals or plastics, this kind of advancement translates directly into real money savings and production gains. The metalworking shops I've talked to recently all mention wanting to upgrade their systems soon, mainly because competitors who adopted these newer technologies first have gained significant market share advantages.

Table of Contents

-

Precision and Accuracy in Metal Fabrication

- Achieving Tight Tolerances with Fiber Laser Cutting

- Superior Edge Quality for Reduced Post-Processing

- Enabling Complex Geometries and Intricate Designs

- High-Speed Cutting for Rapid Production Cycles

- Integration with CNC Laser Cutting Automation

- Reducing Energy Consumption and Operational Costs

- Minimizing Material Waste Through Precision Nesting

- Cutting Capabilities for Sheet Metal and Thick Plates

- Applications in Automotive and Aerospace Manufacturing

- Adapting to Diverse Metals: Stainless Steel to Aluminum

- Adoption Trends in Modern Fabrication Shops

- Future Innovations in Laser Cutting Machine Technology