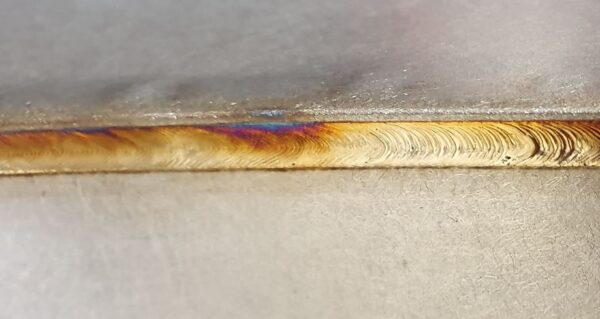

Узнайте, как добиться безупречных лазерных сварных швов на нержавеющей стали благодаря правильной подготовке материала, защите и оптимизации процесса. Узнайте, как Raytu Laser предоставляет индивидуальные решения для обеспечения точности и производительности.

Подробнее

Узнайте о распространенных дефектах при лазерной сварке нержавеющей стали — таких как пористость, трещины, отсутствие сплавления и окисление — а также о проверенных решениях для улучшения качества сварного шва.

Подробнее

Компания Raytu Laser успешно завершила свое участие в выставке FABTECH 2025 в Чикаго, представив новую волоконно-лазерную машину для резки серии HG. Благодаря высокой скорости, точности и компактному дизайну, Raytu укрепила свои позиции ведущего поставщика промышленных лазерных решений для резки на рынке США и глобальном рынке.

Подробнее

Присоединяйтесь к Raytu Laser на выставке FABEX Saudi Arabia 2025, 12–15 октября в RICEC, Эр-Рияд. Посетите наш стенд: Зал 2 – A109-1, чтобы ознакомиться с нашими новейшими станками для волоконной лазерной резки, лазерной сварки и лазерной маркировки. Откройте для себя передовые лазерные решения, созданные специально для вашего бизнеса.

Подробнее

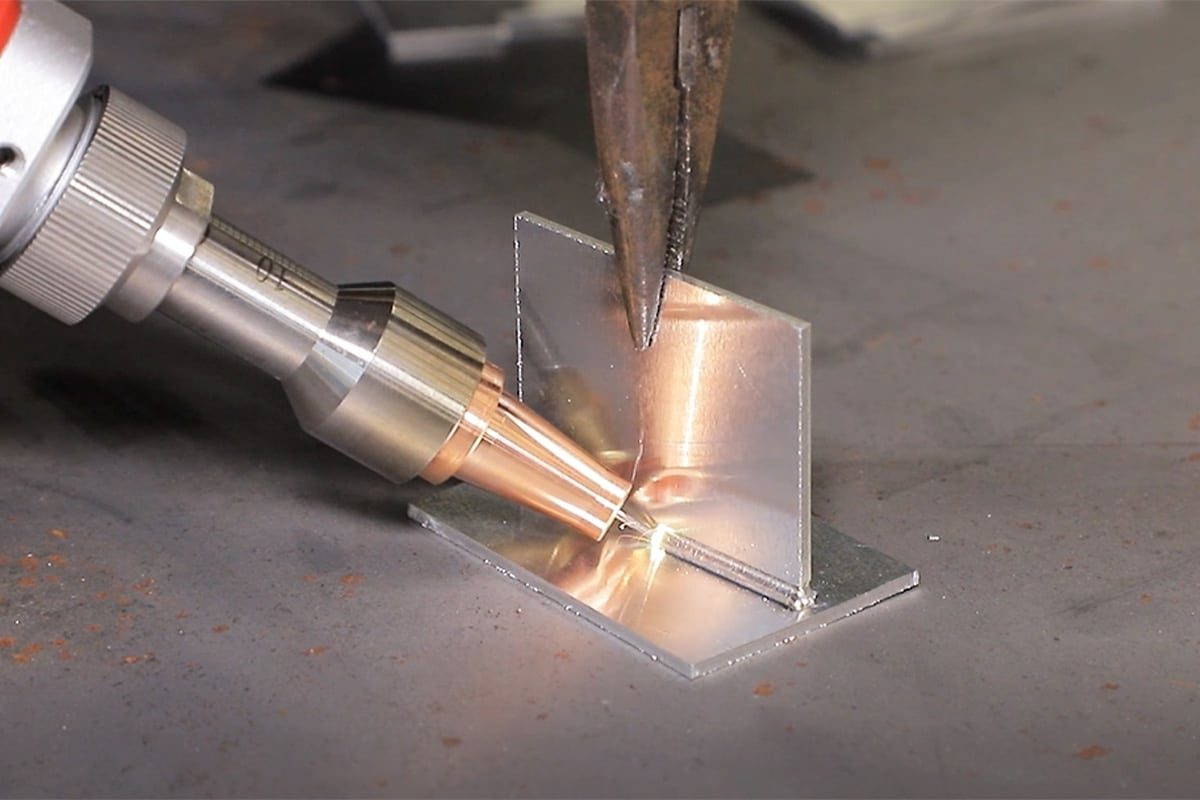

Изучите основы лазерной сварки нержавеющей стали. Узнайте о режимах теплопроводности и ключевого отверстия, непрерывных и импульсных лазерах, а также об основных правилах проектирования сварных швов.

Подробнее

Изучите основы лазерной сварки нержавеющей стали. Узнайте о режимах теплопроводности и ключевого отверстия, непрерывных и импульсных лазерах, а также об основных правилах проектирования сварных швов.

Подробнее

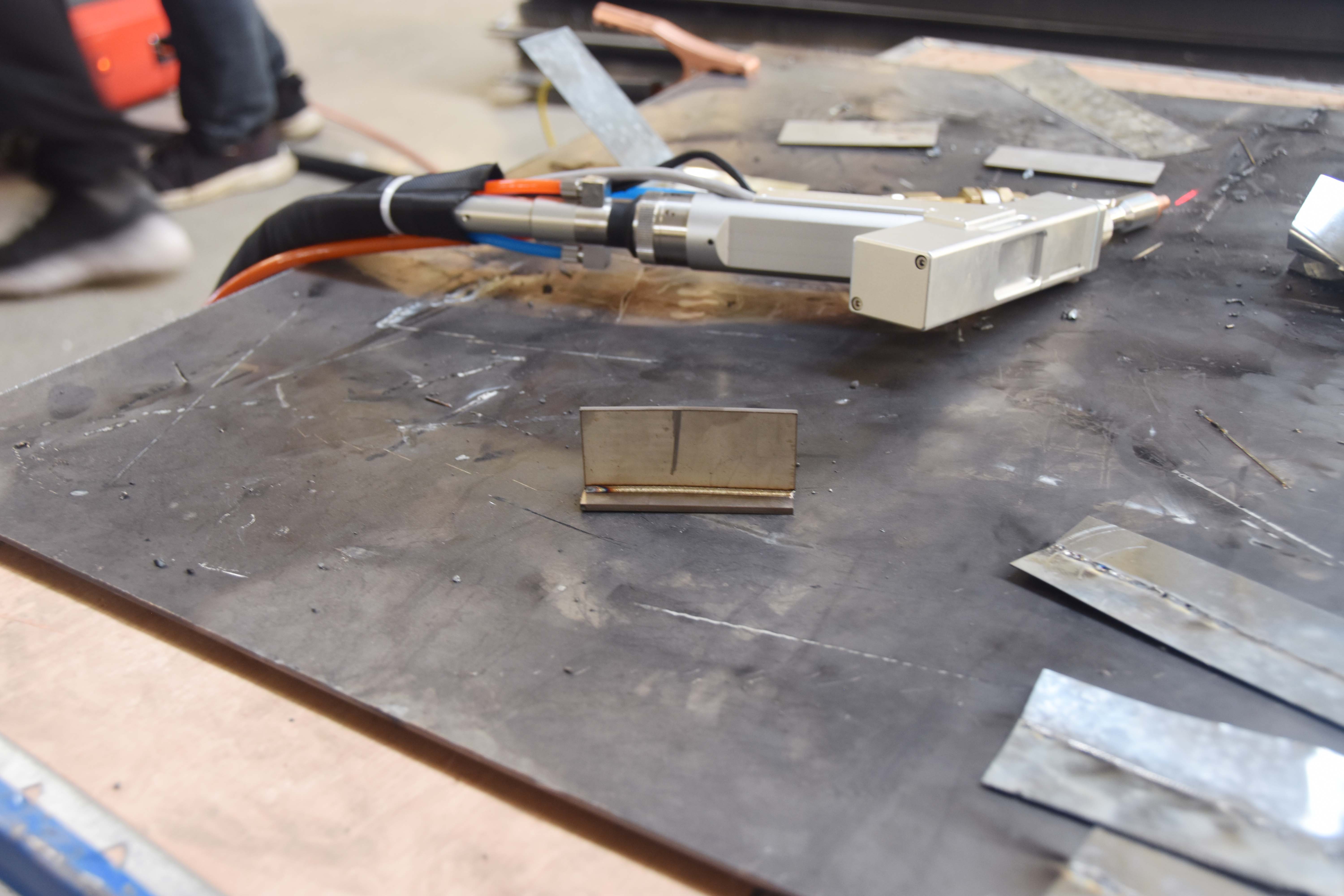

Узнайте основные советы по обслуживанию сварочного пистолета с лазером, чтобы обеспечить стабильную работу. От проверки контактных наконечников и защитных линз до очистки пружинных шлангов — это руководство поможет продлить срок службы вашего лазерного сварочного аппарата и повысить эффективность сварки.

Подробнее

Узнайте, как обслуживать лазерную сварочную машину для обеспечения долгосрочной стабильной работы. От настройки рабочей среды до очистки, калибровки, охлаждения и проверки расходных материалов, это руководство поможет продлить срок службы оборудования и повысить эффективность сварки.

Подробнее

Электрическая система Проверьте автоматические выключатели: Убедитесь, что главный силовой автомат и индивидуальные автоматы питания, включая аварийный выключатель, срабатывают своевременно и эффективно. Проверьте электрические соединения: Убедитесь, что подключение лазерной машины к электропитанию выполнено правильно. Убедитесь надлежащей емкости:

Подробнее

Узнайте, как обслуживать ключевые компоненты лазерной сварки: газовую систему, водяной охладитель и электрическую систему. Обеспечьте качество сварки, эффективность охлаждения и безопасную эксплуатацию.

Подробнее

Важные протоколы безопасности при лазерной сварке! Узнайте критически важные меры предосторожности (защита глаз/кожи/от огня), 8-шаговые проверочные процедуры и 6 механизмов самозащитных систем ручного типа. Соответствуйте требованиям OSHA с помощью нашего проверенного руководства 2025 года!

Подробнее

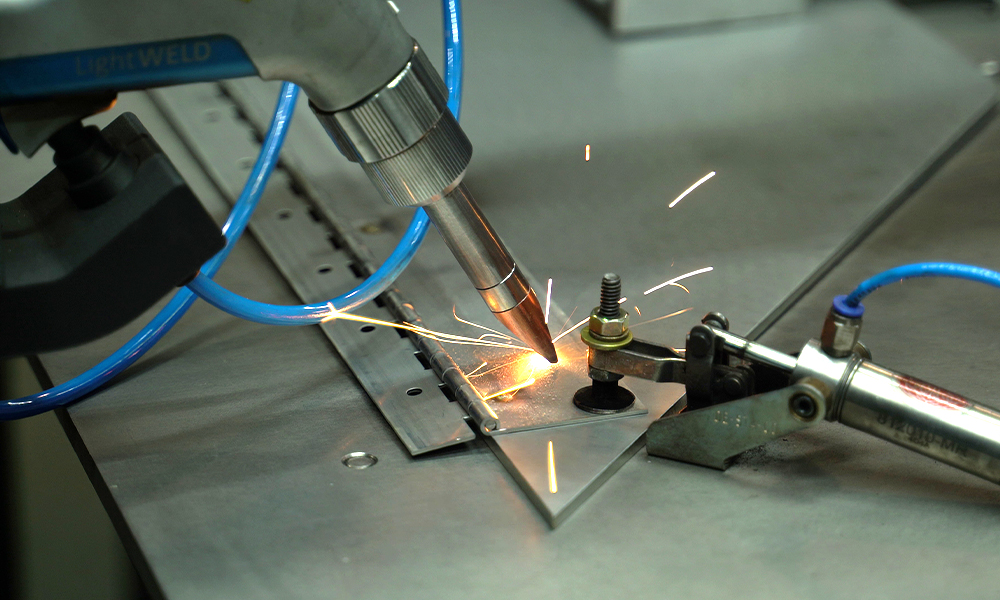

Научитесь правильно управлять лазерной сварочной машиной! Пошаговое руководство по установке, безопасные процедуры эксплуатации, основные меры предосторожности (аргон, охлаждение, калибровка), советы для новичков по получению качественных сварных швов. Начните сваривать как профессионал уже сегодня!

Подробнее Горячие новости

Горячие новости