Understanding Laser Cutting Machines for Business

Laser cutters represent a major leap forward in manufacturing technology, changing the way companies work with all sorts of different materials. The basic idea is simple enough really - these machines direct powerful laser beams at whatever material needs cutting, and depending on how they're set up, they can cut through, engrave details, or even burn away parts of the material completely. What makes this approach so special is that it lets manufacturers produce complex shapes and fine details that would be almost impossible to get using older cutting techniques. For example, jewelry makers can create delicate filigree patterns while industrial fabricators can make extremely accurate components for machinery. Many shops that have invested in laser cutting equipment report significant improvements in what they can produce, often leading to better quality end products across various industries from automotive to aerospace.

Laser cutting machines come in different varieties, mainly differentiated by what kind of laser they employ, which makes them better for certain jobs than others. CO2 lasers tend to be the go-to option when dealing with things like wood, acrylic sheets, or even thick cardboard. They do a great job at both cutting clean lines and detailed engravings on these materials. Fiber lasers work much better with metal stuff though stainless steel and aluminum respond really well to them. The process is faster too, so production runs get done quicker. Then there's tube laser cutting equipment that many manufacturers rely on because it handles round objects so precisely. When looking at all these options, power levels matter a lot depending on what exactly needs to be cut. Some machines just aren't built for heavy duty tasks while others might waste energy on simpler projects.

Key Features to Look for in a Laser Cutting Machine

Laser Power and Cutting Capabilities

When looking at laser cutting machines, one of the key factors to consider is definitely the laser power. Measured in watts, this number tells us roughly what thickness of material the machine can actually cut through without struggling. Higher wattage machines tackle thicker stuff and work much faster too. Take a 100 watt machine for instance it usually handles quarter inch steel pretty easily. But power isn't just about how fast or thick something gets cut. There's another side to it all when it comes to detail work. The really good machines come with better optics and motion systems that let them carve out intricate designs with clean edges. This means less time spent on finishing touches after the fact, which saves both time and money in production settings.

Material Compatibility

Material compatibility plays a key role in picking the right laser cutting equipment for businesses that need flexibility across different substrates. Metal cutting machines exist alongside models optimized for plastics and woods, though some perform better than others depending on what's being processed. Acrylics and textiles often call for adjusted parameters or specific optical components, while fiber lasers stand out as must-have tech for handling tough metals like stainless steel and aluminum alloys. Companies looking at new laser systems should take stock of their regular workload materials first, since this determines whether they get value from their investment down the road.

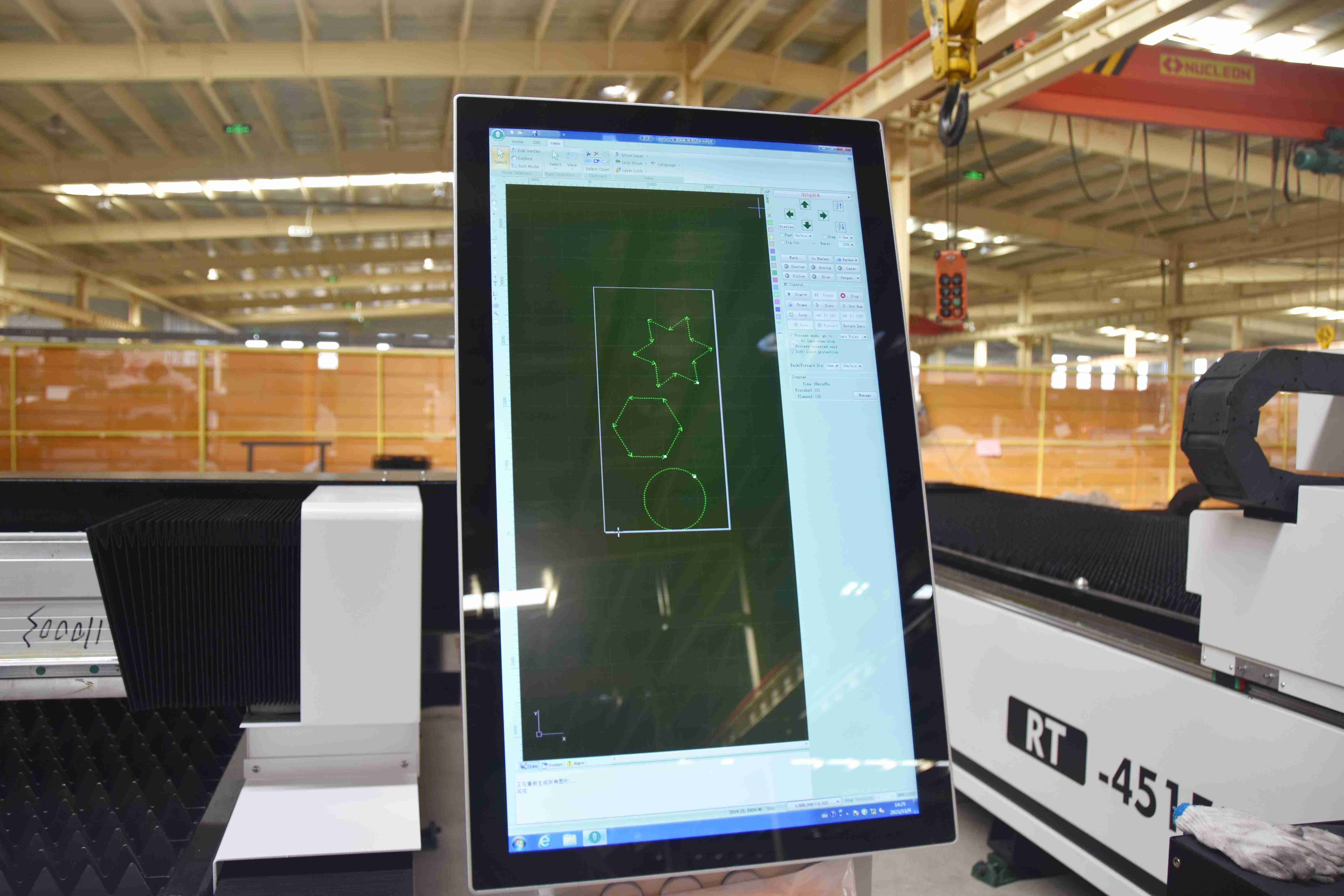

Accuracy and Precision

Getting accurate and precise results matters a lot when it comes to laser cutting operations. The actual measurements determine how well a machine can make repeated cuts that stay within those tight specifications everyone talks about. For companies working in sectors such as aerospace engineering or automotive production lines, meeting these exacting standards isn't just nice to have it's practically non-negotiable. When manufacturers invest in good equipment, they end up with cleaner cuts across multiple pieces, which means better overall product quality and less material going to waste on the factory floor. Many shops report significant savings after upgrading their systems simply because everything just works better together.

Best Laser Cutting Machines for Small Businesses

Top Picks for Small Business Needs

Small businesses often turn to Glowforge and Epilog Lasers when they need affordable laser cutting solutions that won't break the bank. What makes these machines stand out is their versatility across different materials - from basic woods and plastics like acrylic to certain types of metal too. The best part? They deliver decent quality work at a price point most startups can handle. These lasers cut and engrave pretty accurately, so businesses can create nice looking products without spending fortunes on equipment. Plus, the control panels aren't too complicated to figure out. Most owners find themselves up and running within hours rather than days. For shops with limited staff or no tech support team, this ease of use really matters. A local sign shop I know got one installed last month and now handles custom orders much faster than before.

Comparing CO2 vs. Diode Lasers

When deciding between CO2 and diode lasers, small business owners need to think about what exactly they want to cut. CO2 lasers work really well because they handle so many different materials. Wood? No problem. Acrylic sheets? Easy peasy. Even certain metals fall under their capabilities, which makes them pretty versatile for all sorts of jobs around the shop. Diode lasers tell a different story though. These little guys are generally smaller in size and cheaper upfront, which is why lots of folks go for them when doing things like engraving or detailed work on smaller items. The bottom line is knowing what matters most for each business situation. Some will care more about being able to tackle various materials while others might prioritize saving space and money. Getting clear on those priorities helps pick the right tool without breaking the bank or limiting creative possibilities down the road.

Material Considerations for Laser Cutting

Best Materials for Laser Cutting

Small business owners love laser cutting machines because they can handle so many different materials. Wood, acrylic sheets, leather pieces, plus various metals such as aluminum and stainless steel all work well with these tools. But here's the thing: each material behaves differently when exposed to laser beams. The results really depend on what kind of laser system is being used along with how the power levels are set up. Acrylic tends to give those nice clean cuts with sharp edges, same goes for wood products. Metals however need something stronger. They often demand higher powered equipment and much finer adjustments just to get decent results. Getting to know the right settings for each material makes all the difference. Businesses that take time to experiment will find themselves saving money on wasted materials while producing better quality finished goods overall.

Material Thickness and Laser Power

The thickness of the material being cut directly affects what kind of laser power and cutting speed we need for good results. When working with thicker sheets, stronger lasers are required just to get through them properly. Otherwise, the cuts tend to be rough or leave damage on the surface area. Getting the laser power right for the material at hand makes all the difference in how well the cutting goes. Wrong power settings mean either wasted time or those ugly burn marks that nobody wants to see in their final product. Adjustments to laser power aren't just about getting things done faster though. Proper calibration helps maintain quality throughout production runs while keeping the structural integrity intact in everything from sheet metal parts to intricate components used in manufacturing.

Cost and ROI of Laser Cutting Machines

Initial Investment vs. Long-Term Benefits

Getting a laser cutting machine is something companies need to think through pretty thoroughly before making the purchase. Prices jump all over the place really, with basic models starting around $5k while industrial grade units can hit well into six figures depending on what kind of bells and whistles they come with. For most small to medium operations, this represents a major capital outlay so comparing those upfront expenses to actual profit potential becomes essential work. These machines do open up whole new possibilities though. They let shops crank out parts faster than ever before and create detailed patterns that would be impossible with traditional methods. Many manufacturers report seeing their bottom line improve within 18 months after installation as they cut down on manual labor hours and get more done with fewer resources. The real magic happens when shops start taking on custom jobs that competitors simply can't handle.

Calculating ROI for Your Business

Looking at the return on investment for a laser cutting machine isn't just about what it costs upfront. Companies really need to think about all those ongoing expenses too maintenance costs, how much power the thing eats up, but also any money saved when operations run smoother. And there's something else worth mentioning the machine actually creates new ways to bring in cash by letting shops provide better services than before. Customers tend to stick around longer when they get quality work done right the first time, so that loyalty factor definitely counts toward overall value. When weighing out numbers, smart business owners consider not only the obvious money coming in and going out, but also things like standing out against competitors in the marketplace. Taking all these angles into account helps determine whether investing in laser cutting tech makes good business sense long term.

Safety and Maintenance Tips

Essential Safety Features

When working with laser cutting machines, safety should always come first, which means certain features just cant be skipped if we want to prevent accidents from happening. The list starts with good ventilation systems that get rid of those dangerous fumes floating around during operation. Emergency shut off switches are equally important because they let operators cut power instantly whenever something goes wrong. Protective enclosures make sense too since they keep people away from direct contact with the actual laser beam, significantly cutting down injury risks. Following safety rules like OSHA standards isn't just about keeping workers safe either it helps avoid costly shutdowns and production delays that can really hurt business continuity in the long run.

Maintenance Best Practices

Keeping laser cutters running smoothly requires regular maintenance if we want them to last and perform at their best. Cleaning those lenses on a regular basis stops dirt from building up, which messes with how precise the cuts are. Checking the mirrors regularly makes sure they still properly bounce back the laser beam where it needs to go. Don't forget about checking other parts too - things like belts wear out over time and cooling systems get clogged. A quick look around these areas catches small problems before they become big headaches down the road. When shops skip their maintenance routines, they end up facing unexpected shutdowns and expensive fixes that nobody wants to deal with during production hours.