Fiber vs. CO2 Laser Cutting Machines: Matching Technology to Metal and Volume

Why fiber lasers dominate small-batch metal cutting: efficiency, reflectivity handling, and footprint

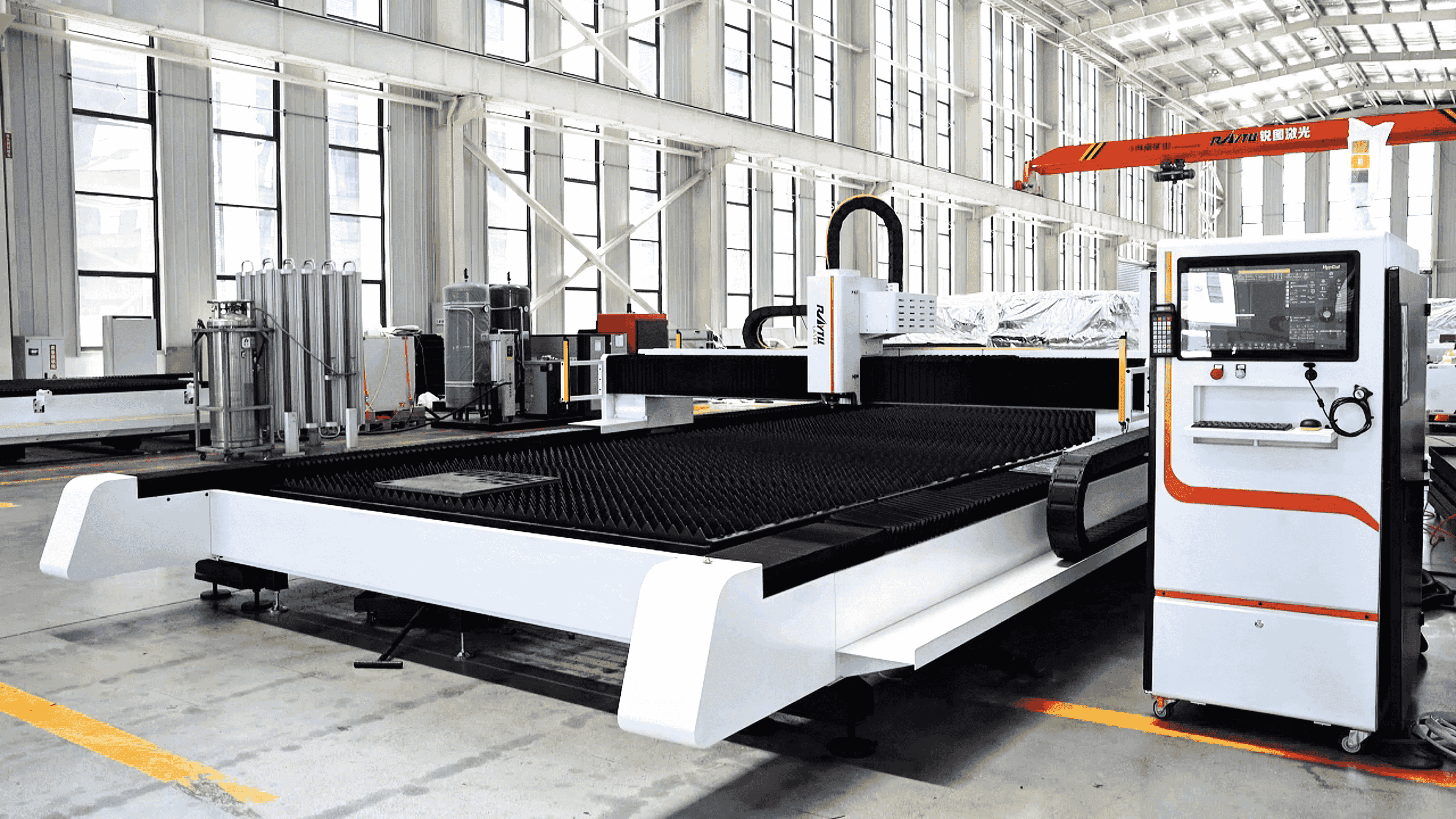

Fiber laser cutters really shine when working with small quantities of metal parts. These machines have a solid state build that makes them much more efficient than traditional gas powered CO2 systems, often saving around 35% or more on electricity bills. One big plus is how they handle reflective materials such as copper and aluminum without causing damage from those pesky back reflections, so there's no need to spend extra money on special anti reflection coatings for the lenses. Plus, these lasers take up way less room in the shop floor space wise, sometimes cutting down footprint needs by almost half which matters a lot in tight workshop environments. When dealing with thinner steel sheets below 6mm thick, fiber lasers typically slice through material about 30% quicker than older CO2 models, meaning prototypes get finished faster and production runs can be turned around sooner.

When CO2 lasers remain relevant: hybrid materials and thick-metal exceptions

There are still situations where CO2 lasers make sense despite newer alternatives. One case is when dealing with materials that aren't just metal but have other components mixed in. Take those rubber bonded metal gaskets for instance. The CO2 laser gets absorbed better by these non metallic parts compared to what fiber lasers can manage. Another scenario involves working with really thick structural steel plates over 15mm. Here the CO2 laser's longer wavelength at around 10.6 microns makes a real difference. The cuts come out straighter with significantly less tapering on the edges something that matters a lot for parts that need to bear weight properly. Thermal issues are another consideration. When running long operations on thick plates, CO2 systems tend to stay consistent for hours without drifting off course like fiber lasers sometimes do when they get hot.

Debunking the 'fiber-only' myth: flexibility in mixed-material prototyping environments

What works best really depends on what kind of materials get used day to day rather than sticking to some tech trend. Shops that switch between different materials all the time like those doing prototype work for airplanes with aluminum parts, titanium components, and composite materials often find it makes sense to keep both laser systems running. Fiber lasers are great when they need to make quick changes to metal pieces, but when there's an acrylic template needed or some insulating polymer part, having that CO2 system on site saves everyone headaches instead of waiting for outside vendors. According to some reports from the FMA folks who track these things, combining both technologies cuts down wait times by around 22% for complicated builds. That kind of speed difference adds up over time in busy manufacturing environments.

Sizing Laser Power to Material Thickness and Batch Requirements

Matching 1–6 kW output to common metals: steel, stainless, aluminum, copper, and brass

Getting the right laser power starts by looking at what kind of material we're working with and how thick it is. Carbon steel that's not reflective and under 4 mm usually works well with lasers between 1 and 2 kW. Things get trickier with stainless steel up to 6 mm thick, plus those shiny metals like aluminum and copper which need around 3 to 4 kW because they reflect so much light and conduct heat differently. When dealing with thicker pieces from 10 to 20 mm, going up to 4-6 kW helps maintain good cutting quality. But watch out for copper and brass though these metals eat up about 20 to 30 percent more power compared to regular steel at similar thickness levels since they just don't hold onto energy as effectively. Finding this balance between power settings and how materials react makes all the difference in avoiding problems like leftover slag, unwanted oxidation spots, or cuts that aren't fully separated.

The diminishing returns of high power: why 3 kW often outperforms 6 kW for thin-gauge, low-volume runs

When working with thick metals, those powerful 6 kW lasers do the job well enough, though they tend to waste a lot of energy when dealing with thinner materials three millimeters or less. Switching down to a 3 kW model actually cuts through thin gauge sheets just as fast, but saves around 25 to 30 percent on electricity costs. And there's another bonus too: the lower power means less heat gets transferred into the surrounding metal area, so critical components maintain their structural properties after cutting. Shops handling smaller runs below fifty pieces will notice real money savings over time thanks to things like using less assist gas and needing maintenance checks far less often. Plus mid range equipment brings flexibility to job shops, allowing faster start up times for piercing operations and making it easier to switch between different part types without losing much productivity.

Achieving Precision and Edge Quality in Complex, Low-Volume Geometries

Managing Kerf Width, Taper, and Heat-Affected Zone (HAZ) for Tight-Tolerance Prototypes

Getting precision right in small batch prototypes depends on managing three main things together: how wide the cut is (kerf), the angle of the taper, and the size of the heat affected area around the cut. When working with parts that need tight tolerances like +/- 0.1 mm which is standard for aerospace parts or medical devices, today's fiber laser systems can make cuts just 0.1 mm wide even in 3 mm thick stainless steel. The taper stays under 0.5 degrees thanks to those adjustable focus settings during cutting. And switching from oxygen to nitrogen as an assist gas makes a big difference too it cuts down the heat affected zone by about 70%. This matters a lot when working with titanium alloys where maintaining fatigue strength after cutting is absolutely essential for long term performance.

| Parameter | Impact on Precision | Mitigation Strategy |

|---|---|---|

| Cutting Speed | Increases taper at high speeds | Optimize for material thickness and geometry |

| Assist Gas (N2 vs O2) | Reduces HAZ by 60–70% with nitrogen | Match gas to material reactivity and finish requirements |

| Focal Position | Controls kerf consistency | Auto-focus systems for complex contours and variable thicknesses |

Adaptive software compensates for kerf displacement during intricate cuts, enabling sharp internal corners and micron-level accuracy. Fine-tuning pulse frequency prevents dross formation on thin metals, while optimized piercing techniques eliminate micro-cracks in copper alloys transforming low-volume laser cutting into a viable solution for mission-critical prototypes.

Optimizing Automation and Software for Intermittent, Small-Batch Production

Streamlining workflows: nesting software, CAD/CAM integration, and one-click setups for batches under 10 parts

When working on those occasional small production runs of metal parts, laser cutters need special software to get the most out of them while keeping costs down per piece. The nesting programs available today are pretty smart about how they place components on sheet metal, which cuts down scrap material significantly even when making just a few items at a time. Some shops report saving around 20% on materials this way. Getting designs from CAD into CAM systems works smoothly these days, so there's no need to manually enter all those complicated shapes into the machine. Just import the file and go. And let's talk about setup times. With one click, operators can bring back previous settings, which saves hours normally spent adjusting parameters between jobs. For runs of less than ten pieces, this makes a huge difference. All this automation helps maintain good quality across batches, gets products out faster, and lets smaller shops compete on price without having to compromise on accuracy or consistency from part to part.

FAQ Section

What are the advantages of fiber laser cutters over CO2 systems?

Fiber laser cutters are more efficient, handle reflective materials better without damage, and have a smaller footprint compared to CO2 systems. They also perform faster when cutting thinner steel sheets.

In what scenarios are CO2 laser systems still preferred?

CO2 lasers are preferred for materials that include non-metal components, such as rubber bonded metal gaskets, and for thick structural steel over 15mm where their longer wavelength provides better quality cuts.

How does laser power output affect cutting?

Laser power must be matched to material type and thickness. Lower power is suitable for thinner materials and helps reduce costs and thermal transfer, while higher power is necessary for thicker materials.

Why is combining fiber and CO2 laser systems beneficial?

Combining both systems offers greater flexibility for shops dealing with diverse materials, speeds up complicated builds, and allows prototyping for a range of components without outsourcing.

How can automation and software optimize small-batch production?

Nesting software, CAD/CAM integration, and automated setup save time, reduce material waste, and streamline workflows, improving efficiency and allowing small shops to remain competitive.

Table of Contents

- Fiber vs. CO2 Laser Cutting Machines: Matching Technology to Metal and Volume

- Sizing Laser Power to Material Thickness and Batch Requirements

- Achieving Precision and Edge Quality in Complex, Low-Volume Geometries

- Optimizing Automation and Software for Intermittent, Small-Batch Production

- FAQ Section