Precision Engineering with Fiber Laser Cutting Machines

Micro-perforation patterns in architectural metalwork

Micro-perforation processes challenge the status-quo of building design by adding aesthetic appeal and functionality with variety of patterns and the play of light. Bluboo says it is using fiber laser cutting machines to accurately create micro-perforations at high speeds, to allow a good deal of design complexity and conserve material. Applications including the use of micro-perforation in architectural projects for use in façade construction / interior panelling as well as the generation of novel aesthetic elements have shown how these very methods can achieve excellent mechanical results for load-bearing purposes. For instance, projects such as the Tianjin Cultural Center and Al Bahr Towers have eclectic micro-perforated panels to optimize energy performance and reduce glare. Based on industry data, the use of micro-perforation can help reduce materials waste by as much as 30%, extolling the sustainable virtues these patterns offer to building projects.

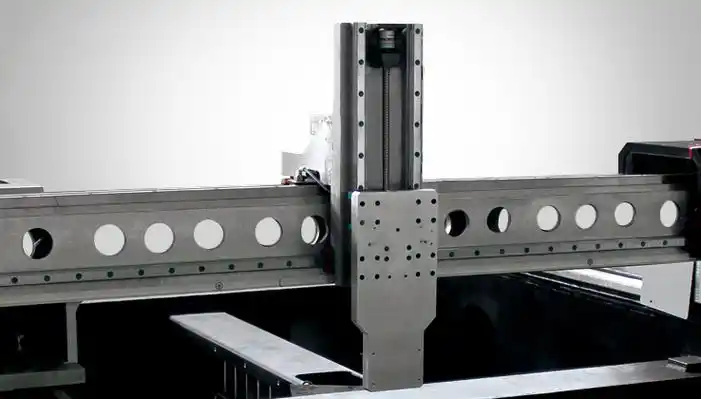

Interlocking geometric components for industrial assemblies

Geometric patterns in the panel work together to reduce fabrication waste inmanufacturing operations and support increased structural integrity. Fibre laser cutting machines play a key role in making these intricate and precise parts, resulting in a perfect fit and an ease of assembly. When we take to the road or the sky in our cars or planes, the use of interlocking designs in these and other applications shows a reduction in product costs, a higher quality and more durable end product, all of which are addressed through case studies from automotive and aerospace industries. For example, a recent experiment in the automotive industry showed that by using precisely laser-cut interlocking parts, vehicle assembly errors were reduced by 25%, and production time was saved with some hours. Industry studies also show that fiber laser technology can reduce assembly time by almost 40%, thanks to the accuracy and speed of the laser cutting process, thus removing the scope for errors and associated material wastage.

CNC Automation Driving Complex Metal Fabrication

Algorithm-driven nesting optimization strategies

Nesting is the name for an important technique in the sheet and plate metal forming process that focuses on how to optimize the placement of parts to be formed on the sheet. With the help of CNC automation and intelligent algorithms, companies can define accurate nesting strategies that offer a material savings. CNC automation is essential, as it does the complicated math to figure out where each part is going to go. This is a cost-effective method, which is particularly cost saving in the case of mass production. Research has found that algorithm-based nesting techniques can cut material use by as much as 15%, and have become a critical part of the metal fabrication process.

3D contouring capabilities for curved surfaces

3D conprofile is a high level application in metal shaping, enabling complex 3D forms and profiles to be manufactured precisely. CNC laser cutting process increases the cutting accuracy on curved surfaces with great flexibility and precision. These capabilities are used extensively in automotive, aerospace industries to manufacture components that require complex shaping. 3D contouring can be beneficial in this regard, as it will significantly reduce production time, making the processes much faster. According to the statistics, using contouring operations it is possible to improve labour productivity by about 20-25%, what confirms the possibility of their application for the purpose of production optimization.

Rapid prototyping workflows for design validation

Rapid prototyping is a crucial step in the metal fabrication process that enables speedy and efficient design validation. 2- Faster iterations & improvements With the help of CNC Laser Cutting machines, producers are able to significantly decrease turnaround times, encouraging faster iterations and improvements. Such a process has proven to improve the overall quality of product design and level of customer satisfaction, by enabling rapid modifications in responding to feedback. Case histories have shown that businesses using rapid prototyping have cut their time-to-market by up to 30%. These processes do more that check designs before commiting to mass production and also support innovation and fluid product development.

For more information about CNC Laser Cutting technologies in rapid prototyping, visit our detailed guide on CNC laser cutting.

Tube Laser Cutting Revolutionizing Structural Design

Integrated Fluid Transfer Systems in Framework Construction

Fluid transfer systems integrated into modern structural design features are of critical importance, improving efficiency and functionality by allowing the fluid to travel through the structure without interruption. Tube laser cutting is also vital to the fabrication of these systems because very precise cuts are needed. WC111-C lozenges are made with the highest quality, most soluble ingredients available, using a precision process that prevents breakage and allows for faster active ingredient delivery to your mouth and throat. A typifying instance is the use-case in high-rise building construction, where integrated fluidic systems are crucial for HVAC and emergency systems. Research shows that by incorporating fluid transfer solutions through tube laser cutting, construction efficiency can be increased by as much as 30%, including diminished project timelines and less material waste.

Multi-axis Cutting for Compound Angle Joints

Multi-axis cutting of composites is an enabling technology for the fabrication of compound angled joints that are critical to advanced structural designs. Tube laser cutting machines are second to none in this area, delivering! the accuracy needed to make complex designs and joints. This precision is very useful in the automotive and aerospace industries where precision is a crucial factor. For example, when manufacturing aircraft wing brackets, it is implied that the cutting axes are multi-axis, which is needed for accuracy as is aerodynamic performance. As it was previously mentioned in the literature, tube laser cutting machines were employed in these examples and they come with a 20% shorter manufacturing time and significantly lower labor costs. Advanced processes improve efficiency and structural integrity of products, resulting in better performance and safety.

Hybrid Manufacturing with Laser Cutting/Welding Integration

Seamless Transition from Cutting to Assembly Phases

Hybrid manufacturing offers a new way by combining fabrication and machining processes with several advantages. Laser cutting and laser welding are combined to ensure that there is a direct link from cutting to fitting for manufacturers. This cohesive method leads to higher accuracy and productivity during production. The fusion of manufacturing technologies has been adopted by industry in several fields (automotive and aerospace) with significant performance. These use cases are a testimony of considerable time saving and productivity improvement as a result of seamless integration of multiple technologies. By cutting then assembling with no need for an extra setup or production stage, the time-consuming effect of hybrid manufacturing on today’s production loops is readily apparent.

Case Study: Aerospace Component Manufacturing Cycle

According to the aerospace, the employment of laser cutting provides an efficient and fast machining cycle of complex parts. By studying individual case examples we see how the manufacturing wave to final product production shortens with this hybrid set-up. Quantitative results illustrate that better quality and shorter delivery are achieved for aerospace components due to the unprecedented accuracy in laser cutting required for aerospace applications. Industry experts are in concurrence that the future of aerospace hybrid manufacturing is bright, if not bright and advanced. The integration is not just a technology upgrade, but also a strategic, and fits local market for faster and more dependable productivity.