What is Laser Welding and How Does It Work?

Laser welding works by focusing intense laser light onto materials, mostly metals, creating joins with remarkable accuracy and speed. Because of its concentrated heat source, this method has found its way into many different fields including cars, planes, and electronic devices where tight tolerances matter. When someone actually performs laser welding, they generate a powerful beam which gets aimed at just one spot on whatever needs joining together. This creates enough heat to melt the material locally before it solidifies again into a solid connection between parts.

Laser welding generally involves two main approaches: conduction welding and keyhole welding. With conduction welding, the process works by transferring heat from the melted material to nearby areas. This creates good quality welds with little spatter or smoke coming off. The metal turns to liquid but stays solid enough not to evaporate completely, which helps keep the heat spread out evenly across the joint. Keyhole welding tells a different story though. This technique creates a deep hole in the material as it melts and actually vaporizes parts of the metal. While this produces stronger connections between materials, there's usually more spatter and sometimes tiny air pockets form inside the weld. Many manufacturers prefer keyhole welding for mass production because it goes faster and gets deeper into the material than conduction methods can achieve.

By understanding these methods, businesses can choose the appropriate technique to achieve optimal welding results for their specific needs, whether they are working with intricate electronics or robust automotive components.

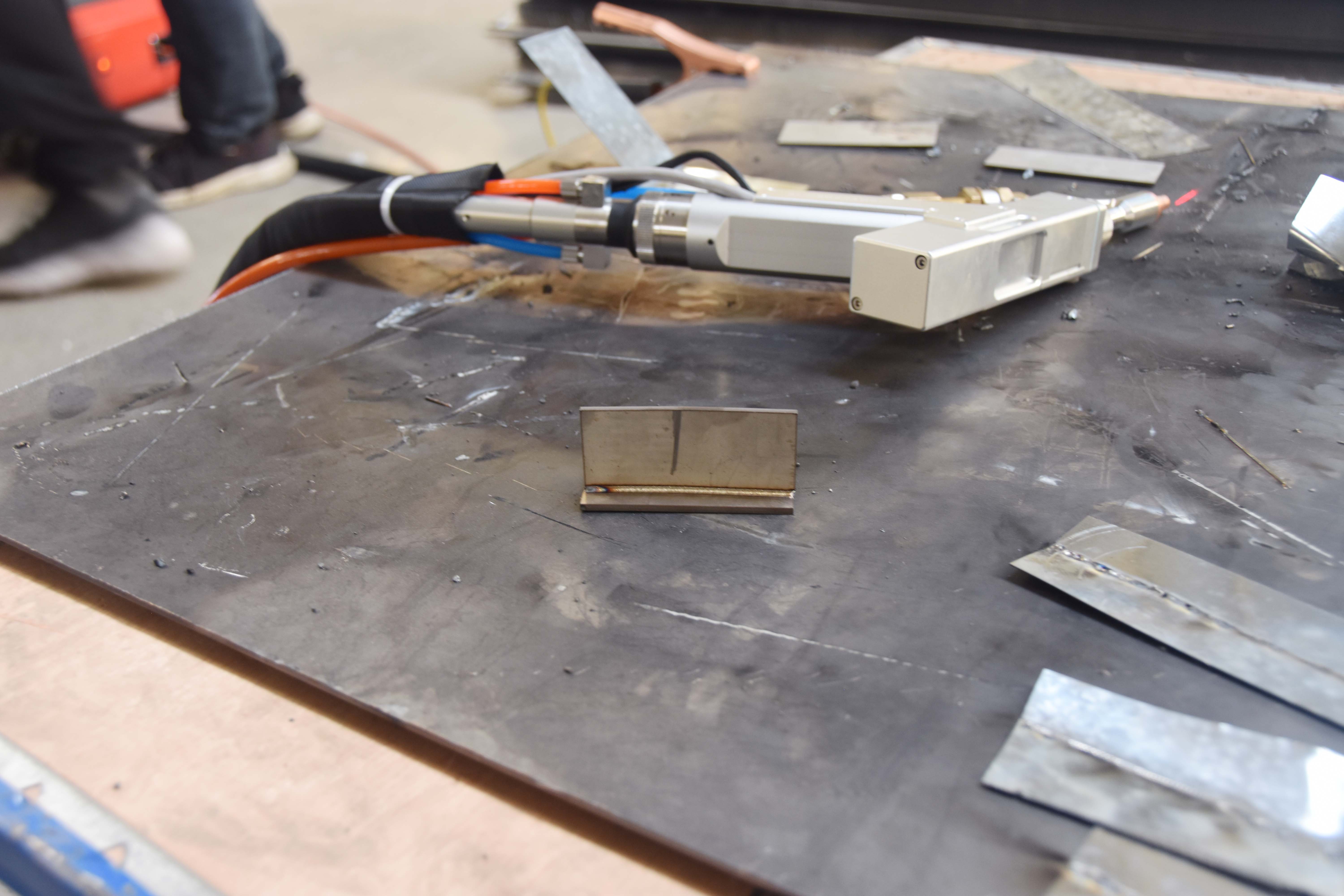

Benefits of Handheld Laser Welding Machines

Increased Precision and Speed

Handheld laser welding gear gives manufacturers a real edge when it comes to getting things done right and fast compared to old school welding techniques. The concentrated laser light lets workers hit those super tight specs they need, making it possible to tackle intricate weld patterns without missing a beat. Production runs get finished way quicker too since these laser units can zip through work at speeds no regular welder could match. For shops in aerospace or medical device manufacturing where quality control is non-negotiable, this combination of pinpoint accuracy and rapid turnaround makes all the difference between meeting deadlines and falling behind schedule.

Reduced Heat Affected Zone (HAZ)

One big plus for laser welding comes down to how small the heat affected zone actually gets. When there's less heat spreading out during the process, it means parts don't warp as much and their original strength stays intact right around the weld area. That matters quite a bit in sectors like aerospace manufacturing or car production, places where getting every measurement just right makes all the difference between success and failure. Handheld models specifically help out here because they create those tight focused beams which result in better quality joins while still keeping the base materials strong enough for whatever application they end up in.

Versatility Across Materials

Handheld laser welders can handle all sorts of stuff from steel to plastic and even composite materials, which is pretty impressive considering how varied these substances are. Because they work so well with different materials, many factories find them useful in everything from automotive assembly lines to medical device manufacturing. Instead of needing separate machines for each material type, companies can just grab one tool and get the job done. The savings add up fast when looking at maintenance costs alone since there's no need to keep multiple specialized welders running. That's why we see these portable laser systems becoming staples in workshops where space matters and budgets are tight.

Why Handheld Laser Welding Machines Are Gaining Popularity

Cost-Effectiveness and Accessibility

Handheld laser welders are getting cheaper these days, which means smaller shops can finally afford them too. What used to be a big ticket item for large manufacturers is now within reach for many midsize operations as well. Running costs also go down because there's less stuff that needs replacing over time, plus machines break down less often. For most workshops, this translates into real savings month after month without sacrificing quality. The metalworking industry has noticed this trend and many shops are upgrading their equipment despite tight budgets simply because the long term math works out better.

Applications in Various Industries

Handheld laser welding machines stand out because they can adapt to different situations while still working efficiently, which explains why so many industries rely on them including car manufacturing, aircraft assembly, and electronic device production. These tools really shine when dealing with delicate materials that have thin walls or when space is limited something that happens all the time in those fields. The fact that these machines work well in tight spots means manufacturers can apply them in ways that weren't possible before, leading to better quality products and new approaches to how things get made on factory floors around the world.

Ease of Use and Training

Handheld laser welding machines focus on being easy to use, so most operators can get the hang of them without spending weeks in training. The way these devices are built makes it simpler for people just starting out to work with them right away. Plenty of training options exist too, which helps folks new to the field pick up what they need to know while also giving companies a chance to build better qualified teams over time. Because they're straightforward to operate and there's good support available for learning, these portable laser welders fit pretty well into regular shop workflows without causing major disruptions.

Comparing Handheld Laser Welding to Traditional Methods

Speed and Efficiency Comparison

Laser welding handheld units work much faster than old school techniques such as MIG or TIG welding. With their concentrated beam of energy, these machines cut down on welding time significantly. Some industry reports point to around a 50% boost in production efficiency when switching to laser technology. For manufacturers dealing with tight deadlines, this time savings makes all the difference. Automotive shops and metal fabrication businesses are increasingly adopting these systems because they simply get the job done quicker without compromising quality. The speed factor alone often justifies the investment for companies looking to streamline their operations.

Quality of Weld and Post-Processing

Handheld laser welding machines tend to produce better quality welds because lasers offer such precise control over the process. With this level of accuracy, there's simply less need for all that extra work after welding is done, which saves money and cuts down on labor costs. Research comparing different methods shows laser welds generally have fewer flaws and actually hold together stronger under stress compared to what comes out of conventional welding setups. For manufacturers working in sectors where strong, reliable welds matter most, like aerospace or automotive manufacturing, switching to laser technology makes total sense from both a quality and efficiency standpoint.

Environmental and Safety Benefits

The handheld laser welding machines produce significantly less smoke and harmful particles compared to old school welding techniques, which is good news for both workers and the environment. Safety wise, there's another plus point worth mentioning these devices don't get nearly as hot as conventional welders do, so they cut down on burns and other injuries caused by intense heat exposure. For factories looking at long term sustainability, switching to laser tech means cleaner air inside workshops plus fewer health risks for staff members who spend their days working around metal. The combination of lower emissions and improved safety profile makes these lasers stand out among traditional options in manufacturing environments across various industries.

Future Trends in Handheld Laser Welding Technology

Advancements in Laser Welding Equipment

Recent breakthroughs in laser tech have transformed handheld welding machines, shrinking their size while boosting power output, which explains why they're gaining popularity among professionals. The improvements tackle real world problems like carrying around heavy equipment and wasting electricity, making these tools practical for everything from auto repair shops to construction sites. Manufacturers keep tweaking things like how much juice they draw and the accuracy of the laser beam, so these welders can actually work alongside traditional machinery without causing headaches for factory managers trying to upgrade their operations.

Integration with Automation and Robotics

Automation keeps driving handheld laser welders to work alongside robotic systems these days, which means better precision and way faster results on the shop floor. These collaborative robots or cobots are becoming pretty common for letting workers interact safely while welding happens. When manufacturers combine these technologies, they get improved accuracy plus quicker turnaround times. The whole welding operation becomes smoother too, so factories run more efficiently without needing constant human oversight throughout every step of the process.

Emerging Applications and Innovations

Handheld laser welding tech is getting better all the time, which means we're seeing it pop up in some unexpected places lately. Medical device makers have started using it for delicate components, while companies building solar panels and wind turbines find it handy too. Some manufacturers are now testing out mixed approaches where they blend laser welding with older techniques. This combination seems to cut down on wasted materials and actually produces stronger joints than either method alone. The real game changer comes when looking at how these improvements let engineers tackle projects that were impossible before. From creating intricate jewelry pieces to repairing aerospace parts mid-flight simulations, the range of possible applications keeps expanding as the technology evolves alongside industry needs.