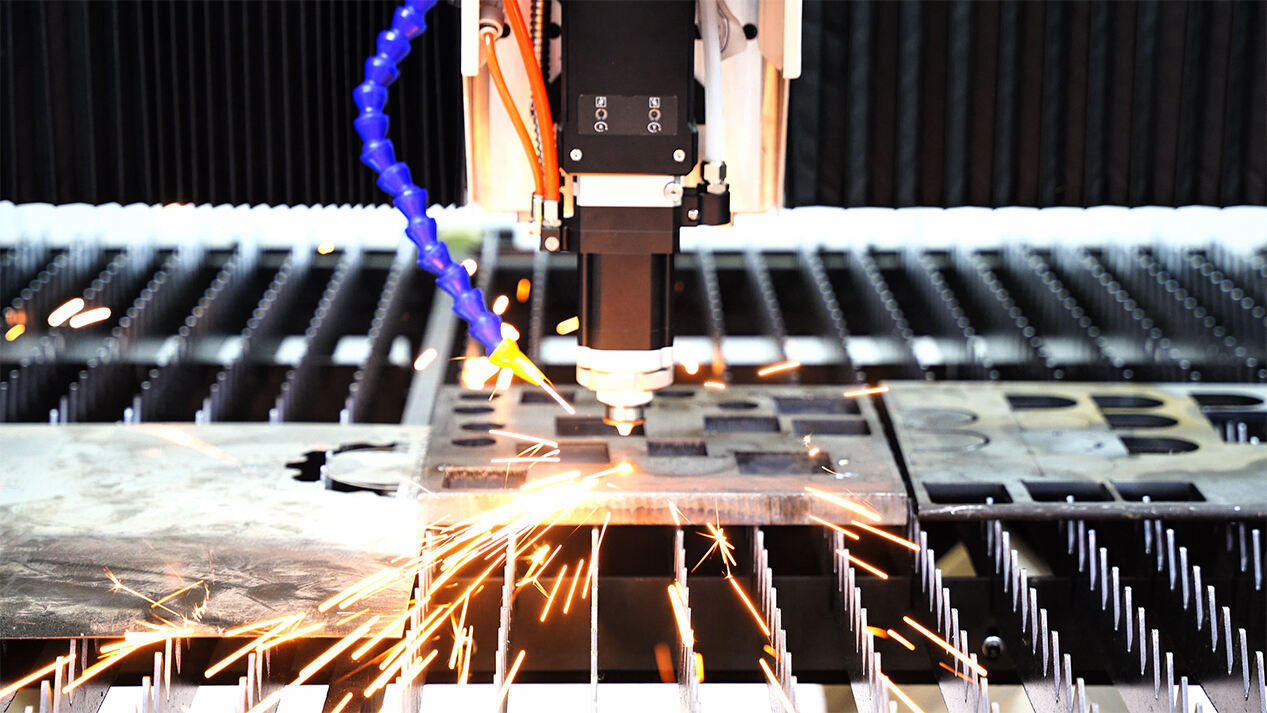

Unmatched Precision and Accuracy in Metal Fabrication

High Beam Quality and Focus Enable Precision in Metal Fabrication

Fiber laser cutting machines achieve micron-level accuracy through collimated light beams 10x more focused than CO2 lasers. This concentrated energy enables precision metal cutting with kerf widths under 0.1 mm, allowing manufacturers to maintain ±0.05 mm tolerances consistently—critical for aerospace and medical components requiring 1:1 dimensional accuracy (2024 Laser Technology Institute study).

Achieving Tight Tolerances With Consistent Accuracy and Efficiency in Metal Cutting

Automated fiber laser systems process stainless steel and aluminum sheets up to 25 mm thick while maintaining 99.8% repeatability across 10,000+ cycles. Unlike plasma cutting, which creates 0.3—1.2 mm deviations, fiber lasers sustain <0.1 mm variance even at 30 meters per minute, reducing material waste by up to 19% compared to mechanical methods.

Superior Edge Quality and Reduced Need for Post-Processing

The non-contact method produces Ra 1.6 µm surface finishes—equivalent to light sanding—eliminating secondary grinding in 83% of applications. A 2023 sheet metal fabrication survey found fiber laser users reduced post-processing time by 42 minutes per 8-hour shift compared to waterjet systems.

Minimal Heat Affected Zone (HAZ) Preserves Material Integrity

Fiber lasers generate HAZ zones <0.25 mm in 3 mm mild steel, 76% narrower than plasma alternatives. This precision prevents warping in delicate materials like 0.5 mm copper sheets and maintains tensile strength within 2% of original specs—crucial for load-bearing components in automotive and defense applications.

Consistent, Repeatable Results in High-Volume Production

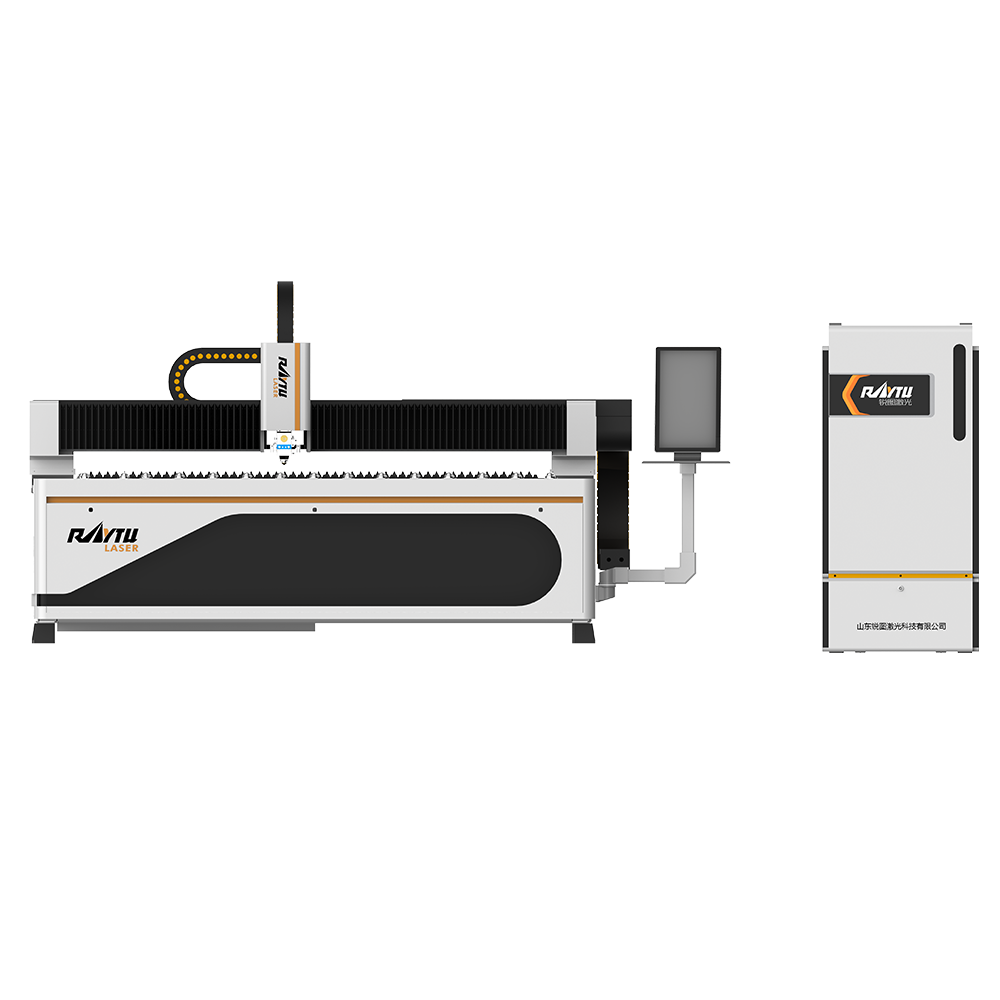

Fiber laser cutting machines deliver unparalleled consistency for large-scale manufacturing operations, addressing the critical need for repeatable quality in high-volume production environments.

Stable Performance Ensures Consistent Quality in High-Volume Production

Advanced cooling systems and adaptive optics maintain ±0.1 mm positional accuracy across 24/7 operations. With no consumable electrodes or gas mirrors, fiber lasers sustain beam intensity for over 100,000 cutting hours (Industry Standard 2023), ensuring uniform results from the first to the thousandth part—unlike plasma systems affected by nozzle degradation.

Greater Control Over Cutting Parameters Enhances Repeatability

Operators can fine-tune power, pulse frequency, and gas pressure with sub-millisecond precision—essential for applications like automotive panel stamping. Integrated sensors automatically adjust parameters for varying thicknesses, reducing material waste by 12—18% compared to CO2 lasers (Fabrication Tech Journal 2024).

Long-Term Reliability of Fiber Laser Cutting Machines

Modern fiber laser systems achieve 98.5% uptime in automotive manufacturing due to solid-state design and minimal maintenance. This reliability cuts operational downtime by 40% over traditional methods, enabling consistent output and on-time delivery in demanding production schedules.

These capabilities position fiber laser cutting as the backbone of high-volume precision manufacturing, where even minor deviations can disrupt entire supply chains.

Advanced Capability for Complex and Delicate Designs

Compatibility with complex geometries in precision metal cutting

Fiber laser cutting machines handle intricate shapes through seamless integration of CAD/CAM software and motion control systems. Manufacturers maintain ±0.05 mm accuracy when cutting multifaceted contours in aerospace brackets and transmission components, achieving a 99.8% first-pass success rate according to 2023 precision engineering benchmarks.

Ability to cut thin and delicate materials without distortion

With a spot diameter typically under 0.3 mm, fiber lasers cleanly cut 0.1 mm stainless steel shims and 0.6 mm aluminum foils with near-zero thermal warping. A 2022 material science study showed an 83% reduction in edge curl compared to CO2 systems when processing 0.5 mm titanium sheets.

Case Study: Aerospace component manufacturing using fiber lasers

A leading aerospace supplier achieved 99.9% dimensional compliance in turbine blade cooling hole patterns after switching to fiber lasers. The non-contact process eliminated tool wear that previously caused a 0.8% scrap rate in nickel alloy components.

Trend: Rising demand for intricate designs in medical device fabrication

The medical device industry shows 34% year-over-year growth in laser-cut microfluidic channels and surgical mesh patterns (2024 Medical Design Report). Fiber lasers now routinely produce 50-micron features in nitinol stents—a critical capability as 78% of cardiovascular implants require customized geometries.

Reduced Material Stress and Cleaner Cut Surfaces

Less Material Stress Due to Non-Contact, Localized Energy Application

Fiber lasers apply energy only to a precise 0.1—0.3 mm zone (Journal of Materials Processing Technology, 2023), eliminating mechanical distortions from physical contact. This localized input reduces residual stress by up to 40% compared to plasma cutting, preserving structural integrity in sensitive alloys like aerospace-grade aluminum.

Improved Cut Quality With Cleaner Edges and Minimal Dross

The focused beam yields roughness values below Ra 3.2 µm, producing clean edges that often require no finishing. A 2023 analysis showed a 92% reduction in dross formation versus CO2 systems, enabling direct assembly in medical device manufacturing and slashing post-processing time by 30—50%.

Thermal Management Advantages Over Plasma Cutting

| Factor | Fiber Laser | Plasma |

|---|---|---|

| Heat-Affected Zone | 0.1—0.5 mm | 1.2—2.5 mm |

| Peak Temperature | 1,500°C | 25,000°C |

| Distortion Risk | Low | High |

Operating at 1/15th the temperature of plasma arcs, fiber lasers prevent warping in thin-gauge materials under 2 mm—allowing precise cutting of 0.3 mm brass shims without compromising flatness.

Energy Efficiency and Long-Term Cost Benefits

Energy Efficient Laser Cutting Reduces Operational Costs

Modern fiber laser cutting machines consume up to 35% less energy than CO2 lasers while maintaining comparable speeds (LaserTech Institute 2023). This efficiency lowers electricity costs for high-volume shops, while automation optimizes material usage and minimizes scrap.

Lower Power Consumption Compared to CO2 Lasers and Plasma Systems

Fiber lasers operate at 30—50% lower electrical input than CO2 systems for thin metals. Plasma alternatives require 2—3 times more energy for similar tasks, according to industrial energy consumption benchmarks. The non-contact process also avoids additional power drains from mechanical handling.

Sustainability Benefits of Automated Fiber Laser Cutting Systems

Integrated automation enhances sustainability through:

- Predictive maintenance algorithms that reduce unnecessary power draw

- Smart nesting software that minimizes raw material use

- LED-based work area lighting consuming 80% less power than halogen options

High Initial Cost vs Long-Term ROI in Metal Fabrication

While fiber laser machines carry 20—40% higher upfront costs than plasma systems, their 25,000+ hour lifespan delivers multi-year savings. Users typically recover the investment through energy efficiency and productivity gains within 18—32 months, as shown in 2023 metal fabrication ROI studies.

Frequently Asked Questions

What are the precision capabilities of fiber laser cutting machines?

Fiber laser cutting machines can achieve micron-level accuracy with kerf widths under 0.1 mm and maintain tolerances of ±0.05 mm, crucial for aerospace and medical components.

How does fiber laser cutting reduce material waste?

Fiber lasers maintain a variance of less than 0.1 mm, which reduces material waste by up to 19% compared to mechanical methods.

What are the advantages of fiber laser cutting over plasma cutting?

Fiber lasers have a narrower heat-affected zone, lower distortion risks, and consume less power. Additionally, they provide better edge quality with minimal post-processing needs.

How energy efficient are fiber laser cutting systems compared to other methods?

Fiber lasers consume up to 35% less energy than CO2 lasers and operate at 30—50% lower electrical input for thin metals compared to other methods.