Laser Cutting Technology: Precision Engineering for Modern Manufacturing

Core Principles of Laser Cutting Machines

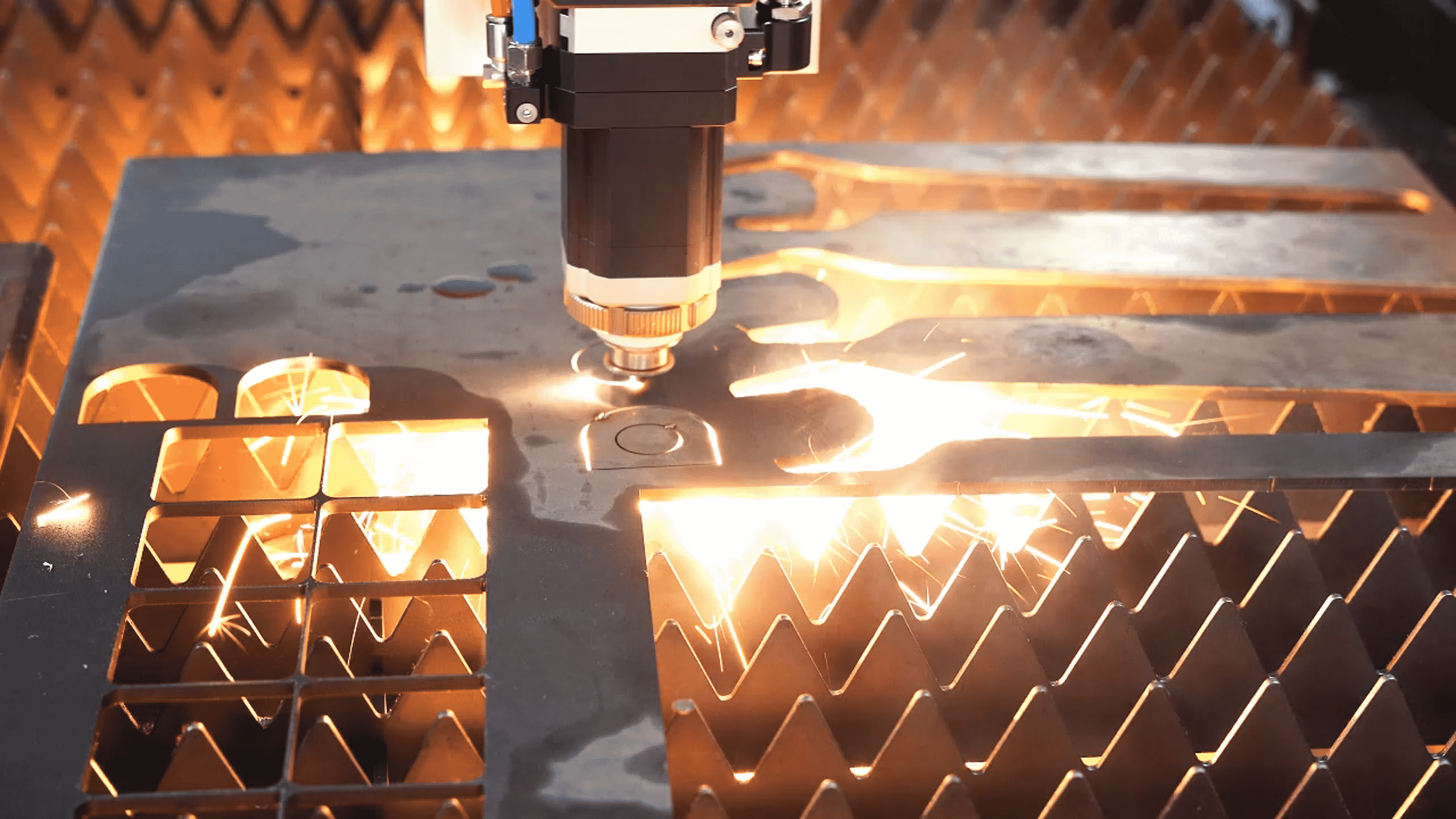

Laser cutting machines have become essential tools in today's manufacturing world. They work by focusing a powerful laser beam onto materials including metals, plastics, and even certain fabrics. What makes this technology so effective is how it converts intense light energy into heat that cuts through materials with remarkable precision while leaving very little waste at the edges. Getting good results really depends on picking the right kind of laser for the job. Traditional CO2 lasers were once the standard but fiber lasers are becoming increasingly popular these days because they handle different materials better. For instance, fiber lasers tend to perform well on reflective surfaces where CO2 might struggle. Several important factors determine how well a cut turns out. Power levels matter a lot, along with how fast the machine operates and where exactly the laser focuses its energy. Sticking close to recommended settings generally leads to better outcomes. Material characteristics also play their part. Thicker materials require more power, and reflective surfaces need special handling to avoid damaging the workpiece during the cutting process.

Achieving Microscopic Tolerance Levels

Industries such as aerospace manufacturing and electronic component production demand extreme accuracy, often requiring tolerances down to fractions of an inch. Laser cutting stands out in these fields because it can hold incredibly tight specs, sometimes as precise as plus or minus 0.001 inches on critical parts. What makes this possible? The technology allows for repeated passes across tiny sections while keeping heat buildup minimal, something traditional cutting methods struggle with when working on delicate materials. Modern software tools give technicians better control over complex designs, letting them tackle specifications that would have been impossible just a few years ago. Keeping laser systems properly calibrated and well maintained isn't optional either. These machines need regular attention to stay within those narrow tolerance ranges day after day. Without this kind of care, even the most advanced equipment won't meet the quality requirements demanded by high tech manufacturing environments.

Mass Production Capabilities of Industrial Laser Cutters

High-Speed Automation and Throughput Optimization

The speed of industrial laser cutters is changing how manufacturers approach production, with these machines able to crank out parts at impressive rates. What makes them so valuable is their ability to run non-stop without needing someone to watch over them every second, meaning factories can keep producing around the clock. Manufacturers have started integrating things like robotic arms alongside conveyor belts to minimize downtime between operations, getting more done in less time. There's also smart software now that automatically tweaks settings while cutting based on what kind of material it encounters and how thick it is. This kind of flexibility matters a lot when switching between different jobs throughout the day. According to recent studies looking at factory floor data, companies using fast laser cutting tech typically see anywhere from 25 to 30 percent improvement in overall productivity numbers compared to traditional methods.

Material Efficiency in Large-Scale Processing

Getting the most out of materials matters a lot when it comes to saving money in large scale manufacturing, and laser cutters really stand out here. Traditional cutting methods leave behind quite a bit of waste, but lasers create almost no leftover scraps. This means manufacturers can nest parts together more strategically on sheets of material, making better use of every inch. The precision also lets designers pack more components onto one sheet without compromising quality. Another big plus is how these machines handle complicated shapes all in one go, which cuts down on extra steps like grinding or machining that would otherwise eat into materials. According to industry reports, businesses that switch to laser cutting often see around 20% less wasted material. That translates to real dollars saved while also helping companies meet their green goals at the same time.

Technological Evolution in Laser Cutting Systems

Advancements in CNC Control Systems

Computer Numerical Control (CNC) systems have changed the game for laser cutting technology, giving manufacturers much better control and precision during the cutting process. With modern CNC setups, we can program all sorts of complex designs into machines, which means producing custom parts with really detailed specs isn't such a big deal anymore. The result? Even those tricky shapes and complicated patterns get cut accurately, something that used to be a real headache for many shops. These systems come equipped with real time feedback features too, so operators can keep an eye on what's happening during cuts and tweak things as needed to maintain quality standards across entire production runs. Industry reports suggest that when companies upgrade to advanced CNC controls, they often see around a 40% reduction in setup times. That translates to quicker turnaround for jobs and generally better shop floor efficiency.

Integration of IoT and Real-Time Monitoring

Bringing IoT technology into laser cutting machines has created opportunities for constant monitoring and gathering data throughout operations, which helps predict when maintenance is needed and keeps things running smoothly. These monitoring systems keep an eye on important factors like how fast the machine cuts and the strength of the laser beam. When something starts to go wrong, operators get warnings so they can fix issues before they become big problems, maintaining top performance most of the time. The whole setup cuts down on unexpected stoppages while boosting output levels, which means lower expenses over time. All this data collected in real time gives managers valuable insights they need to fine tune their processes. They can see exactly where improvements are possible and make better decisions about how resources should be used across different parts of production.

Industry Applications Driving Laser Cutting Demand

Aerospace and Defense Precision Components

The aerospace and defense industries have seen growing interest in laser cutting tech because they need parts made with extreme accuracy for both safety reasons and how well their systems perform. With lasers, manufacturers can create all sorts of complicated shapes out of tough materials that would be nearly impossible with older techniques. This matters a lot when making things like airplane frames or missile parts where even small errors could lead to major problems down the line. For instance, drone manufacturers rely heavily on laser cut components since they need lightweight yet durable pieces that fit together perfectly. Some studies point to around a 20% drop in manufacturing time when switching from conventional cutting methods to laser technology. That kind of time savings translates directly into cost reductions while maintaining those critical quality standards required in aviation and military equipment production.

Automotive Manufacturing Efficiency

Laser cutting has become a game changer for efficiency in car manufacturing, especially when producing large volumes of parts. The tech can slice through metals like steel and aluminum with precision, creating intricate shapes that meet the specific needs of both electric cars and conventional models. What makes this technology so valuable is how it combines flexible design options with fast production times, allowing factories to keep pace with changing vehicle designs without major retooling costs. Some real world examples show manufacturers who adopted laser cutting systems saw their production efficiency jump by around 25%. While not every shop can afford these systems right away, those that do often find themselves ahead of competitors struggling with older methods.