Material Compatibility Considerations

Metal Cutting Capabilities

Laser cutting tech has completely changed how we work with metal, giving manufacturers much better precision and flexibility for all sorts of jobs. Metal cutting really benefits from laser tech, and among these options, fiber lasers stand out as being super versatile when dealing with different materials like steel, aluminum, brass, and copper. The way these metals conduct heat and what temperature they melt at makes them great candidates for laser work. Take steel for instance it melts at a fairly low temperature and conducts heat well, which means laser processing works pretty efficiently. Fiber lasers have become increasingly popular in recent years because they offer better precision while also saving money compared to older cutting methods. Industry data shows fiber lasers actually perform around 200% better than CO2 lasers when working on thinner metals. More shops are switching to fiber laser technology now because it just plain works better for detailed work and big production runs alike.

Sheet vs. Tube Processing Needs

When it comes to laser cutting, sheet metal and tubes require completely different setups. For sheets, flatbed systems are pretty much standard because they need to stay stable throughout the whole cutting process just to get those clean edges right. Tubes tell a different story though. Working with them brings all sorts of headaches like keeping things rotating properly while still maintaining enough stability. That's why special equipment like rotary attachments became necessary over time. The world of tube laser cutting has changed quite a bit lately. Manufacturers have been working hard on making their machines better at handling these tricky jobs. We've seen some real progress with new rotary systems coming onto the market within the last few years specifically designed to tackle those pesky tube cutting problems. These newer systems let operators rotate parts smoothly without losing stability, which is absolutely critical when dealing with complicated tube designs. Since tubes come in so many shapes and sizes, modern machines now offer much greater flexibility across different profiles. This means better results overall and fewer headaches for shops that deal with tubular components regularly.

Thickness Range Requirements

How well a laser cutting machine works depends a lot on how thick the material is that needs cutting. Operators need to tweak power settings just right depending on what they're working with, so things run smoothly without wasting time or materials. Most industries have set rules about what's too thick or too thin for different lasers, which helps keep everyone safe while getting good results. When dealing with heavy metals like steel plates, companies need equipment that packs serious punch in terms of laser power if they want those nice clean edges. Take fiber laser cutters for instance these newer models actually handle thicker metals better than older CO2 systems did back in the day. They cut through everything from thin gauge sheets used in automotive parts all the way up to massive structural components for buildings. The whole metal fabrication business keeps changing though, so manufacturers keep improving their tech to meet whatever comes next whether it's super detailed work on delicate alloys or tough jobs requiring brute force cutting power.

Fiber vs. CO2 Laser Comparison

Choosing the right laser cutting equipment means knowing how fiber lasers differ from CO2 models. Fiber technology works with shorter wavelengths which metals absorb much better, so these machines excel at cutting through metal sheets. That's why many shops opt for fiber laser systems when working with steel or aluminum. CO2 lasers work differently though they produce longer wavelength beams that cut better through non-metal materials such as plastic sheets or wooden panels. Most manufacturers find fiber lasers quicker and cheaper to run because they consume less electricity and require fewer repairs over time. Some real world tests have actually found fiber lasers can cut materials about three times faster than traditional CO2 units. Because of this speed advantage, most large scale metal fabrication facilities now rely heavily on fiber laser technology to meet their production demands.

Power Output Considerations

How much power a laser cutting machine produces really affects how fast and clean the cuts will be. Higher power lasers slice through thick stuff quickly, but if the power is too low, we often end up making several passes which just slows everything down. When choosing settings, matching the right power level to what needs cutting makes all the difference. Metals usually need more muscle behind them so higher wattage works best there, while plastics generally get along fine with less intense beams. Most shops stick to lasers rated between 2 and 4 kilowatts when working on metal pieces. Thinner materials don't require such heavy hitters though. Getting familiar with these power relationships helps pick the right machine for the job without overcomplicating things or wasting time on unnecessary upgrades.

Beam Quality and Precision Factors

The quality of the laser beam plays a major role in determining how accurate and precise laser cuts will be when working with metals. The M squared value basically tells us how close a real laser beam comes to the theoretical Gaussian shape it should have. Lower numbers here mean better focus and sharper cuts overall. Good focusing lenses make all the difference too, allowing fine adjustments even when materials vary slightly in thickness or composition. For industries where precision matters most, like aerospace manufacturing and electronic component production, fiber lasers have become pretty much standard equipment. They deliver those clean cuts with very tight tolerances needed for complex parts that just wouldn't work if there was any sloppiness in the process.

Cutting Performance Metrics

Speed vs. Precision Balance

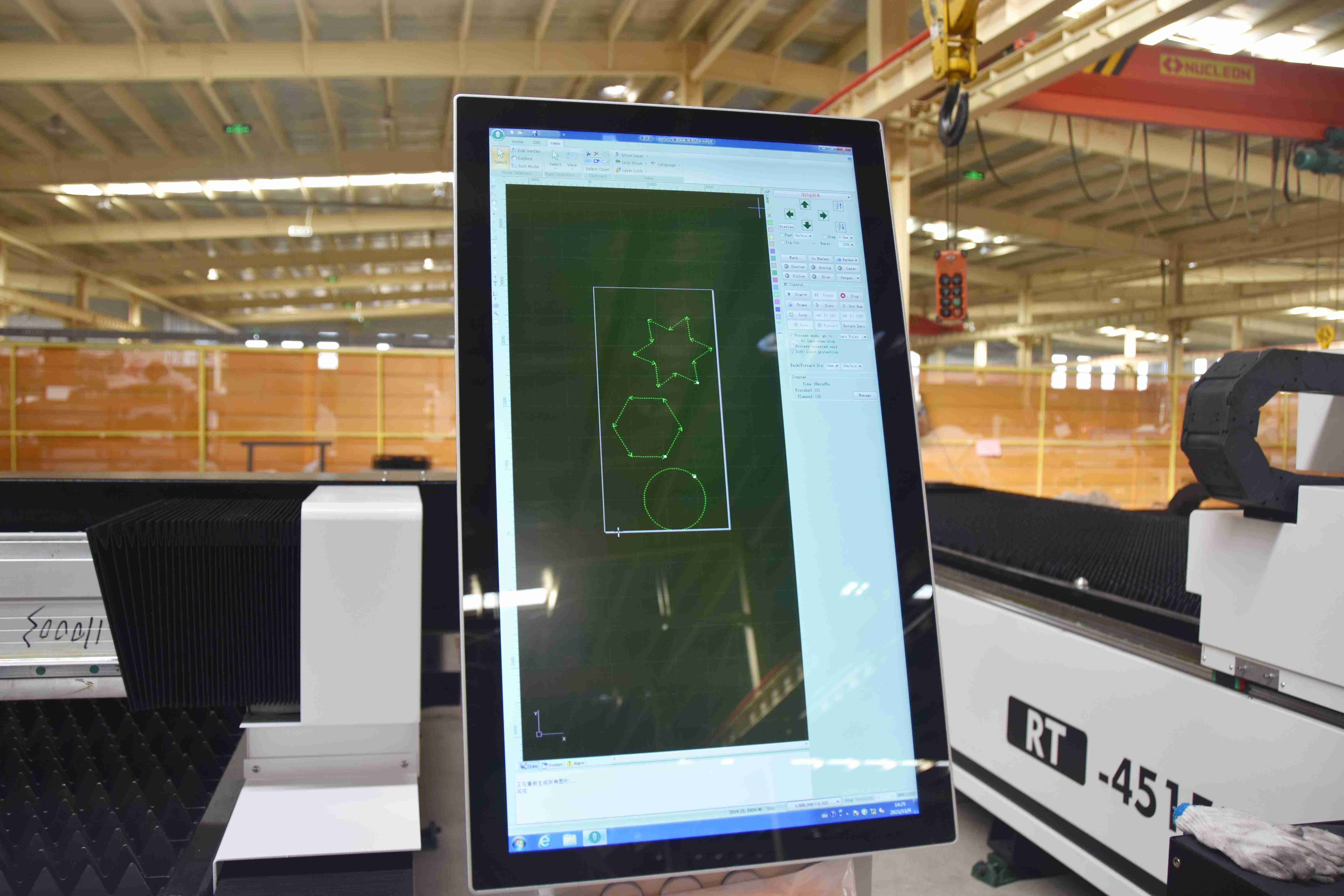

Finding just the right mix of speed and accuracy matters a lot when working with laser cutters. These machines come with adjustable settings for different jobs, but knowing what gives up what is pretty important. When someone needs really detailed work like complex patterns or fine details, slowing down the machine actually makes sense to get those clean cuts right. On the flip side, big manufacturing runs where every second counts can afford to crank things up since tiny imperfections won't matter much there. Take one car parts factory we looked at recently. They had trouble keeping up with demand while maintaining quality standards. After tweaking their laser cutter settings based on material thickness and design complexity, they managed to boost output without sacrificing too much on quality. Their production manager said finding that sweet spot made all the difference in meeting deadlines without compromising product integrity.

Edge Quality Expectations

When it comes to laser cutting results, edge quality remains one of the most important factors to consider. This includes looking at how rough or smooth the surface appears after cutting, plus checking if there's any noticeable taper where the top and bottom edges don't match up. Getting good edge quality really depends on setting the right parameters for the job. The machine needs to be calibrated properly based on what kind of material we're working with. Take thick metal sheets for example many operators find that slowing down the cutting speed on fiber lasers helps minimize those annoying tapers that can mess up precision work. We've seen this time and again through our customers who consistently mention how much they appreciate clean, straight edges without any waviness or unevenness. It just makes sense when someone wants their parts to fit together perfectly every single time.

Kerf Width and Material Waste

Getting a good grasp on kerf width makes all the difference when it comes to making the most out of materials during laser cutting operations. Simply put, the kerf refers to how wide the actual cut ends up being after the laser does its work. When the kerf gets too wide, that means more wasted material which adds up fast for any manufacturer. The size of the kerf varies depending on what kind of laser setup we're talking about and the material being worked on. Take sheet metal cutting for instance, where industrial lasers tend to produce much narrower cuts because they can focus better on those thin sheets. According to shop floor experience, companies that invest in laser systems capable of tight kerf control see noticeable reductions in scrap rates. Cutting down on that extra width might seem small but over time it translates into real savings across production runs.

Operational and Cost Factors

Energy Efficiency Analysis

Looking at laser cutting machines means paying attention to how much power they eat up and what that does to the bottom line. The truth is, some machines drink electricity while others sip it. Fiber lasers tend to be much more efficient than old school CO2 models, which makes them cheaper to run day to day. Better efficiency cuts down both money spent and carbon footprint left behind. What actually helps these machines save energy? Good question. Modern systems come with better beam delivery tech and smarter software that keeps components from sitting idle when they don't need to. Research published in places like Journal of Cleaner Production backs this up showing real world savings for shops switching to newer fiber tech. Picking a machine with solid energy specs isn't just about saving cash over time it changes how manufacturers approach their whole equipment buying strategy.

Maintenance Requirements

Keeping laser cutters well maintained really makes a difference in how long they last and how good they perform overall. For both fiber and CO2 models, regular attention to things like lens clarity and keeping those cooling systems clean is absolutely necessary. When shops stick to proper maintenance schedules, they avoid those frustrating unexpected shutdowns and get better cuts across the board. Most technicians will tell anyone who asks that fiber lasers are actually easier to work with since there aren't so many moving parts inside them. CO2 versions need constant checking because of all those internal components that wear out faster. Reading through what the manufacturers recommend isn't just paperwork either it matters for day to day operations. That's why so many fabricators gravitate toward fiber lasers especially when working with steel sheets. They just don't break down as often and save money on repairs in the long run.

Total Ownership Costs

Getting a laser cutting machine requires a big financial commitment. The price tag isn't just about buying the equipment itself but also covers running costs and regular maintenance. When we look at all the expenses involved in owning these machines, there are actually pretty big differences between different kinds of lasers. Fiber lasers tend to cost more upfront, sure, but they save money in the long run because they use less power and need fewer repairs. On the flip side, CO2 lasers start off cheaper but end up costing more due to their higher maintenance needs. Some manufacturers who switched to fiber laser technology saw their production rates go up while spending less overall, according to recent studies in manufacturing economics journals. For anyone shopping around for laser cutting solutions for metal sheets, taking a close look at what it really costs to own and operate each type makes all the difference in getting value for money.

Understanding these operational and cost factors is vital in determining the most suitable laser cutting machine for your needs. By considering energy efficiency, maintenance requirements, and total ownership costs, you can make strategic decisions to optimize performance and manage expenses effectively in laser cutting technology.