Energy Efficiency and Environmental Benefits of Laser Welding Machines

How Laser Welding Machine Technology Reduces Energy Consumption

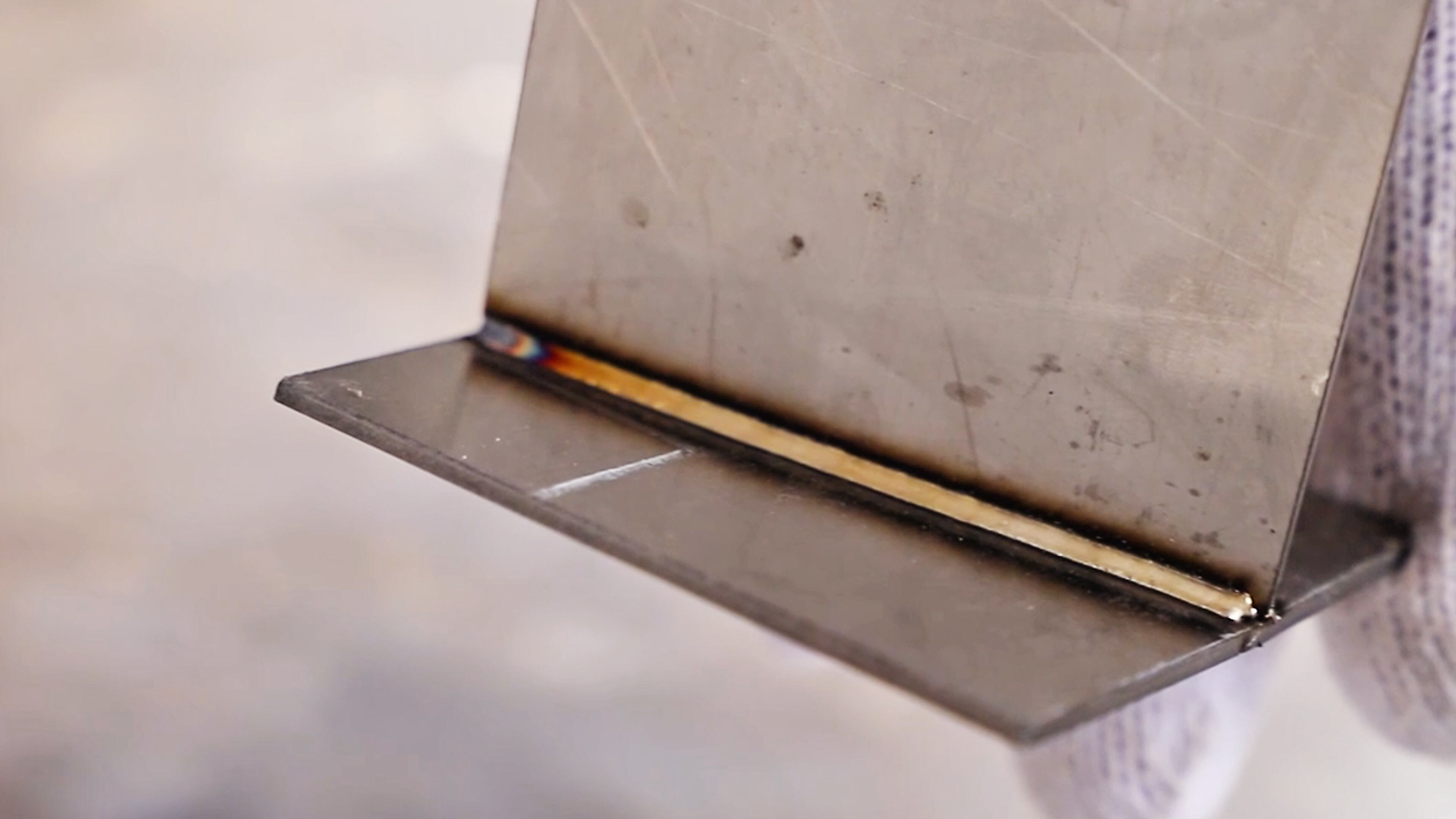

Laser welding machines focus their energy right where it needs to go, heating only the actual weld area and keeping unwanted heat from spreading out. Unlike old school welding that needs constant power to keep those arcs going, lasers work differently. According to recent industry data, pulsed laser systems cut down on wasted energy during downtime by around 20 to 35 percent. Another big plus is that since there's no physical contact involved, we don't lose energy fighting electrode wear and tear. Plus, these machines can automatically adjust their power levels as they work, changing strength depending on how thick the material is. This real time adjustment makes everything run smoother and saves even more energy in the long run.

Comparative Energy Efficiency: Laser Welding vs. Traditional Arc Welding

| Metric | Laser Welding | Arc Welding |

|---|---|---|

| Energy Use per 1m Weld | 0.8–1.2 kWh | 3.5–4.2 kWh |

| Thermal Diffusion | 0.3–1.2 mm | 4–8 mm |

| CO₂ Equivalent per Hour | 2.1 kg | 9.6 kg |

According to the International Institute of Sustainable Manufacturing, laser systems complete equivalent tasks using 68% less energy than MIG welders. Their narrow heat-affected zones reduce or eliminate the need for post-processing steps like straightening warped components, which are both time-consuming and energy-intensive.

Decreased Emission of Hazardous Fumes Compared to Conventional Welding Methods

Laser welding cuts down on airborne particles by around 83% because it doesn't need those consumable electrodes or filler materials that traditional methods like flux-cored arc welding do. According to the 2023 Clean Manufacturing Survey results, most laser welding setups don't produce harmful hexavalent chromium or manganese fumes at all. About 92% showed none, compared to just 34% for TIG welding. What does this mean for factories? They can actually shrink their ventilation systems without violating OSHA's air quality rules. And shrinking those systems means saving money upfront when building facilities and cutting ongoing maintenance expenses too.

Lower Carbon Footprint Enabled by Laser Welding Machine Automation

Integrated automation features—such as collision avoidance and predictive maintenance—reduce energy waste from unplanned downtime by 17–24%. Centralized power management in fiber laser systems optimizes energy distribution across multiple workstations, cutting annual carbon emissions by 38 metric tons per production line when compared to manual welding setups.

Precision and Resource Efficiency in Material Utilization

Reduction in material waste through precision joining with fiber laser cutting machine

Fiber laser cutting machines achieve material utilization rates of up to 92%, significantly outperforming plasma cutting’s 68%, according to a 2025 materials efficiency study published in Nature Scientific Reports. With a kerf width of just 0.2mm and positional accuracy within ±0.1mm, these systems enable tightly nested layouts that maximize sheet usage:

| Cutting Method | Material Utilization Rate | Kerf Width | Energy Consumption |

|---|---|---|---|

| Fiber Laser | 92% | 0.2mm | 8.5 kW/hr |

| Plasma | 68% | 3.1mm | 24 kW/hr |

This level of precision translates to raw material cost savings of 18–22% in sheet metal fabrication, particularly beneficial when working with high-value materials such as aerospace-grade aluminum and corrosion-resistant steels.

Minimizing raw material loss using laser cutting machine for metal

Because laser cutting is a non-contact process, it eliminates tool wear gaps inherent in mechanical shearing. This preserves an additional 15–20% of raw sheet metal per production run. For projects involving expensive alloys—where material costs can represent 60–70% of total expenses—this efficiency directly improves profitability and sustainability.

Extended tool life and reduced consumables in handheld laser welding machine operations

Handheld laser welding systems do not require consumable electrodes or shielding gases, reducing supply costs by up to 85% compared to MIG/TIG processes. Their solid-state design supports operational lifespans exceeding 10,000 hours, far surpassing the typical 500-hour lifespan of conventional welding torches under heavy use.

Economic Sustainability and Long-Term Operational Advantages

Total Cost of Ownership Analysis for Fiber Laser Cutting Machine Systems

Laser welding and cutting systems tend to cost less overall because they eat up about 30 to 40 percent less energy and basically take care of themselves when it comes to maintenance. Take fiber laser cutting machines for instance these typically guzzle around half the power compared to plasma options out there. And let's not forget about automation which can save shops roughly eight bucks twenty cents every hour on labor costs according to some research done back in 2023 by Ponemon Institute. Looking at real world examples, many manufacturing plants have seen their wallets fatten up by nearly ninety two thousand dollars over five years thanks to fewer breakdowns, less need for replacement parts, and simply getting more work done in the same amount of time.

ROI Timelines in Medium-Scale Manufacturing After Integrating Laser Welding Machines

Medium-sized manufacturers typically achieve return on investment within 18–24 months after replacing arc welding systems with laser technology. As highlighted in the 2024 Manufacturing Efficiency Report, integration leads to 27% faster production cycles and 15% higher material utilization. Additional savings from reduced waste and eligibility for ESG-related incentives further accelerate breakeven timelines.

Strategy: Phased Integration to Align With Sustainability KPIs

A structured rollout ensures smooth adoption while advancing sustainability goals:

- Pilot testing with handheld laser welding units in low-risk applications

- Workforce retraining focused on precision joining techniques

- Full-scale deployment of fiber laser cutting machines in primary production lines

This phased strategy minimizes upfront investment and helps meet 65–80% of annual sustainability targets without disrupting operations.

Case Study: Automotive Component Manufacturing Achieving 30% Lower Emissions

One European car parts manufacturer slashed its carbon footprint by around 132 metric tons each year when it switched from traditional spot welding techniques to modern laser welding technology. When they optimized their metal cutting processes using these laser systems, they managed to reduce wasted materials by nearly 20%, which translated into total savings of about $2.1 million across three years according to IndustryWatch in 2023. This investment not only helped them meet stricter environmental regulations but also made good financial sense for their bottom line over time.

FAQ

What are the main energy savings with laser welding machines?

Laser welding machines significantly reduce energy waste by focusing energy precisely and adjusting power levels in real time. They use about 68% less energy than traditional MIG welders.

Do laser welding machines emit fewer hazardous fumes?

Yes, laser welding machines reduce airborne particles by approximately 83% and produce none of the harmful hexavalent chromium or manganese fumes common in conventional methods.

How much can material waste be reduced using laser cutting machines?

Fiber laser cutting machines can achieve material utilization rates of up to 92%, leading to raw material cost savings of 18–22% in sheet metal fabrication.