Precision and Non-Contact Cleaning: How Laser Technology Enhances Surface Treatment

How Laser Cleaning Works: The Science Behind Selective Ablation

Laser cleaning systems work by firing short bursts of light at surfaces to blast away dirt and grime through a process called selective ablation. Basically, the material being cleaned absorbs certain wavelengths of light while leaving other parts untouched. Operators can tweak settings like how long each pulse lasts from nanoseconds right down to femtoseconds, plus adjust the energy levels so they can zap away stuff like rust spots or old paint layers without harming what's underneath. One big advantage is that there's no physical contact involved, which means no tool wear issues. According to research published by MIT back in 2023, these lasers can actually remove material with incredible accuracy within just +/- 0.02mm.

Superior Control in Delicate Applications Like Aerospace and Automotive Components

Laser systems have become pretty much standard in aerospace manufacturing for removing thermal barrier coatings off turbine blades. These systems hit around 99.6 or 99.8 percent accuracy most of the time, which keeps those critical nickel alloys intact so engines last longer. The automotive industry benefits too when it comes to cleaning weld seams on aluminum panels. Even tiny bits of leftover material at the micron level can actually weaken the whole structure over time. What makes lasers stand out compared to old school chemical solvents is they don't leave behind any messy secondary waste products. Factories report cutting down their rework rates by roughly 15 to 20 percent across various high precision manufacturing operations since switching to laser technology.

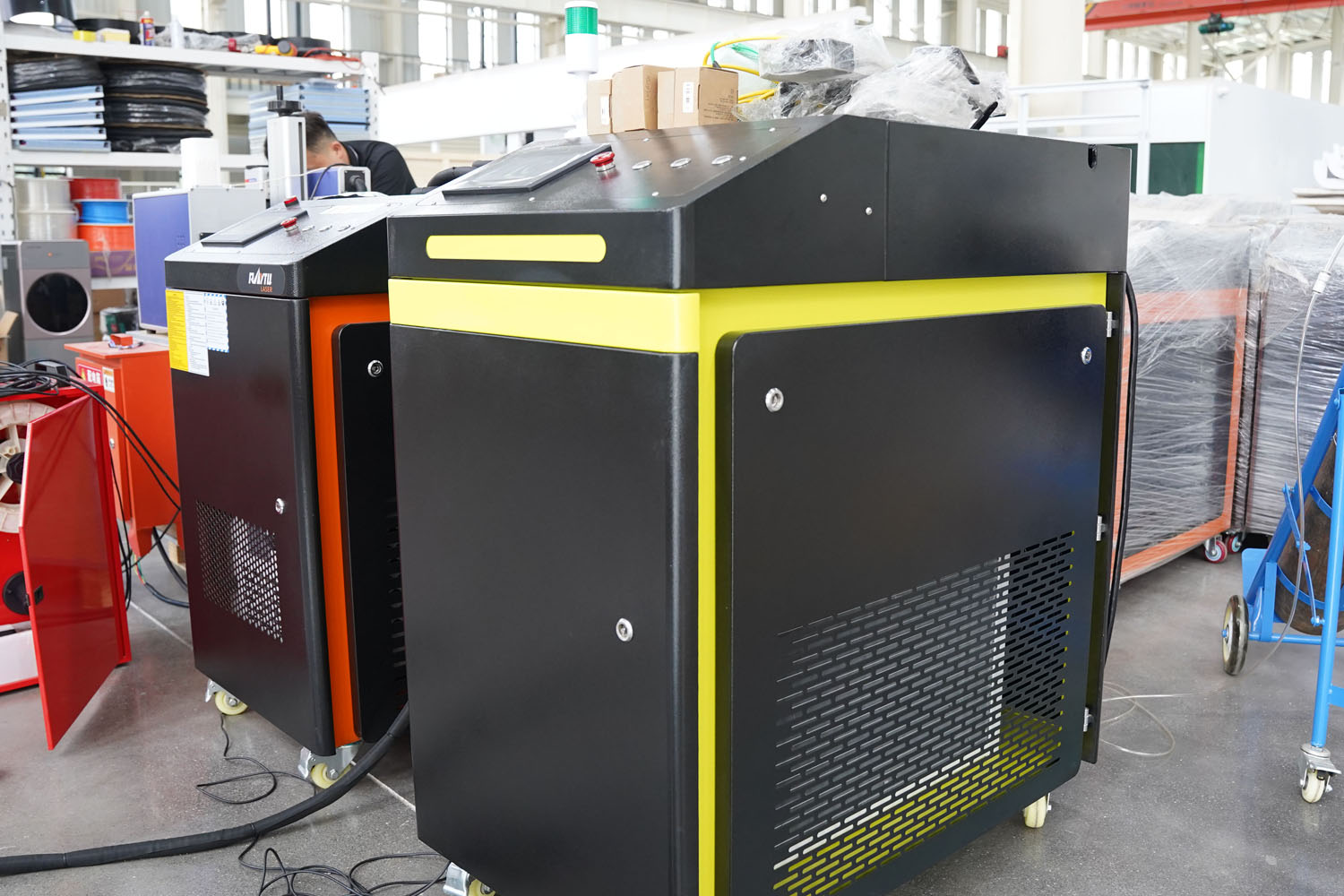

Case Study: High-Precision Welding Preparation Using Laser Cleaning Machines

One major car parts manufacturer made the switch from abrasive grinding to laser pre-cleaning when working on aluminum battery casings for welding applications. Their new system strips away oxidation layers pretty quickly actually around 15 square centimeters per second while keeping the surface roughness under control at less than Ra 1.6 micrometers. After testing these changes, they found weld defects dropped by about 30 percent overall, and the bonds between materials ended up being roughly 22 percent stronger than what they got using old school techniques. The company estimates this has saved them somewhere around $1.2 million each year just from fewer warranty issues related to faulty welds in their products.

Environmental and Safety Benefits Compared to Traditional Methods Like Sandblasting

Laser cleaning tackles some big problems facing industries today, especially when it comes to protecting the environment and keeping workers safe. Take sandblasting for instance. The stuff creates around 300 to 500 kilograms of abrasive waste every single hour according to what the EPA has found. Laser technology changes this completely by getting rid of those harsh chemical solvents and cutting down on dangerous leftovers through a process where it basically turns away the dirt without touching the surface itself. What makes this approach so good is that it works within all the strict EU REACH rules while also preventing any kind of follow-up pollution issues that can happen with other methods.

Eliminating Chemicals and Reducing Hazardous Waste in Industrial Cleaning

Most traditional cleaning approaches depend heavily on silica blasting materials and various chemical stripping agents, which account for around 38% of all industrial toxic waste according to OSHA data from 2024. With laser cleaning technology, things work differently. The process targets oxides, rust spots, and different types of coatings using what's called photothermal reactions. What remains after treatment is just fine particulate matter that gets caught in standard filtration systems. Take for example a metal fabrication facility somewhere in Ohio that saved themselves from dealing with 12 whole tons worth of solvent disposal each year simply by making the switch to lasers for their mold maintenance needs. The savings were substantial both financially and environmentally speaking.

Reducing Worker Exposure and PPE Costs with Non-Abrasive Laser Cleaning

Sandblasting requires NIOSH-approved respirators and full protective suits due to respirable crystalline silica exposure. Laser cleaning reduces PPE requirements by 60% (Journal of Occupational Safety, 2023) through enclosed work cells and integrated fume extraction. Workers can handle treated substrates immediately, free from chemical residues or dust contamination.

Case Study: Replacing Sandblasting in Shipbuilding with Laser Rust Removal

A shipyard reduced drydock cleaning time by 75% after adopting laser technology for hull maintenance. The system removed 0.8 mm-thick marine rust at a rate of 3 m²/hour without damaging the underlying steel. This eliminated 2,400 kg/day of blasting waste and saved $18k per month in hazardous material handling fees.

Preservation of Base Materials Without Damage During Surface Preparation

Avoiding Substrate Degradation Common in Mechanical and Chemical Cleaning

Old school techniques such as sand blasting or using chemicals to clean surfaces often end up damaging materials over time. Research published in Surface Engineering Journal back in 2023 found that some aluminum samples lost around 15% of their thickness after being subjected to harsh cleaning processes. Laser cleaning works differently by selectively removing only what needs to go. The laser vaporizes stuff like rust spots and oxide layers without touching the actual metal underneath. This approach stops those tiny cracks from forming and keeps pores from developing, which matters a lot for delicate parts. Think about gearboxes inside machinery or those intricate turbine blades used in power plants where even small defects can cause big problems down the line.

Optimizing Laser Parameters for Maximum Material Integrity

Consistent results are achieved by tuning three key variables:

- Pulse duration (nanosecond vs. picosecond) to control heat-affected zones

- Wavelength matched to contaminant absorption characteristics

- Fluence levels calibrated to substrate hardness

For example, a 1064 nm fiber laser effectively removes carbon deposits from titanium aerospace alloys without affecting fatigue resistance—a significant advantage over media blasting.

Case Study: Refurbishing Aerospace Components Without Surface Warping

One major aircraft manufacturer saw their wing spar rejection rate drop dramatically - down by nearly 92% - once they started using laser cleaning to tackle corrosion issues. The company managed to keep surface roughness under 1.6 micrometers Ra, which actually goes beyond what's required by ISO 8501-3 standards. This improvement meant they could save around $2.8 million worth of parts each year that would have otherwise gone straight into the scrap pile. Thermal imaging showed temperatures only rose about 5 degrees Celsius during the treatment process, so those delicate composite layers stayed intact without any damage from excessive heat exposure.

This non-abrasive approach reduces material waste by 85% compared to mechanical grinding and ensures consistent surface profiles for optimal coating adhesion, extending part life in extreme operating conditions.

Operational Efficiency and Integration into Automated Manufacturing Systems

Laser cleaning machines offer measurable operational advantages when integrated into modern manufacturing environments, particularly due to their compatibility with Industry 4.0 automation standards.

Achieving Consistent, Repeatable Results for ISO-Compliant Surface Cleanliness

Laser systems that are automated take out the guesswork from human operators since they can be programmed with exact energy levels ranging between 2 to 20 joules per square centimeter and pulse times anywhere from 5 to 200 nanoseconds depending on what material is being worked on. Research published last year in Sustainable Manufacturing showed something interesting too when companies started combining their laser operations with OEE tracking software. The results? About a 22 percent drop in process inconsistencies when compared against traditional hand-based abrasive techniques. This kind of consistency makes it much easier to meet those tough ISO 8501-1 requirements for proper surface prep without constant quality checks throughout production runs.

Automating Laser Cleaning in Production Lines for Higher Throughput

Robotic integration allows laser cleaning systems to process components at speeds up to 10 m²/hour while maintaining micron-level accuracy. The factory automation market is projected to reach $370 billion by 2034, driven by technologies that reduce unplanned downtime by 39% in automotive assembly lines.

Long-Term Cost Savings Despite Higher Initial Investment

Laser systems do cost about 20 to 40 percent more upfront compared to traditional sandblasting equipment, but this extra expense pays off big time when looking at long term savings. The biggest money saver comes from not having to constantly buy abrasive materials or solvents anymore. Plus, these systems actually cut down on energy consumption somewhere around 55 to 70 percent. And let's not forget maintenance either – over those first five years, companies report seeing their maintenance bills shrink by roughly three quarters because there's just so much less mechanical wear and tear involved. Aerospace manufacturers who've run the numbers through proper lifecycle analysis back up these claims, showing real world benefits beyond just theoretical calculations.

FAQ

What is selective ablation in laser cleaning?

Selective ablation is a process where laser technology is used to remove specific materials from a surface by selectively absorbing certain wavelengths of light without affecting other parts.

How does laser cleaning benefit industries like aerospace and automotive?

Laser cleaning offers superior control in removing coatings and impurities without damaging critical materials. It increases accuracy, reduces waste, and improves efficiency, especially in aerospace and automotive manufacturing.

What are the environmental benefits of laser cleaning compared to sandblasting?

Unlike sandblasting, which produces a large amount of abrasive waste, laser cleaning reduces hazardous waste and avoids the need for chemical solvents, making it more environmentally friendly.

Is laser cleaning cost-effective in the long run?

Despite higher initial costs, laser cleaning saves money over time by reducing material and energy consumption, minimizing maintenance expenses, and increasing operational efficiency.

Table of Contents

- Precision and Non-Contact Cleaning: How Laser Technology Enhances Surface Treatment

- Environmental and Safety Benefits Compared to Traditional Methods Like Sandblasting

- Preservation of Base Materials Without Damage During Surface Preparation

- Operational Efficiency and Integration into Automated Manufacturing Systems

- FAQ