How Fiber Laser Cutting Machines Excel in Metal Processing

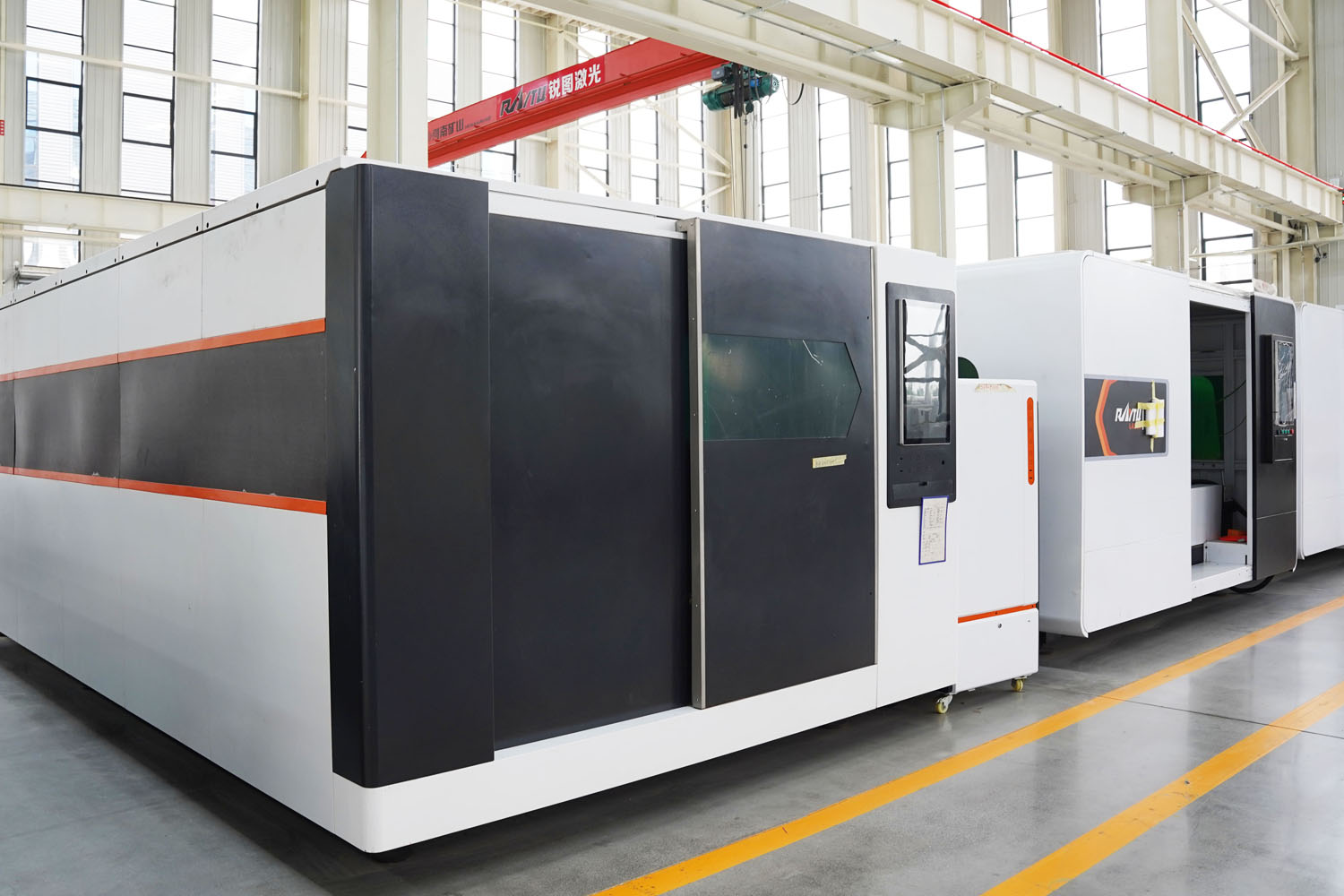

Understanding Fiber Laser Cutting Machines and Their Dominance in Metal Fabrication

Fiber laser cutting machines changed the game for metal fabrication shops everywhere because they produce those super focused, intense laser beams capable of achieving really fine details down to microns. What makes these systems stand out is how efficient they are at turning electricity into usable light energy around 95 percent efficient which is almost twice as good as older CO2 laser tech. And when it comes to actual cutting speeds, fiber lasers can slice through metals about thirty times quicker than traditional plasma cutting methods according to data from the 2023 Fabrication Technology Report. This kind of speed boost means factories can crank out products much faster without sacrificing quality, making fiber lasers a smart investment for manufacturers looking to increase their output capacity.

Laser Parameters Affecting Cutting Efficiency and Quality: Power, Speed, and Spot Size

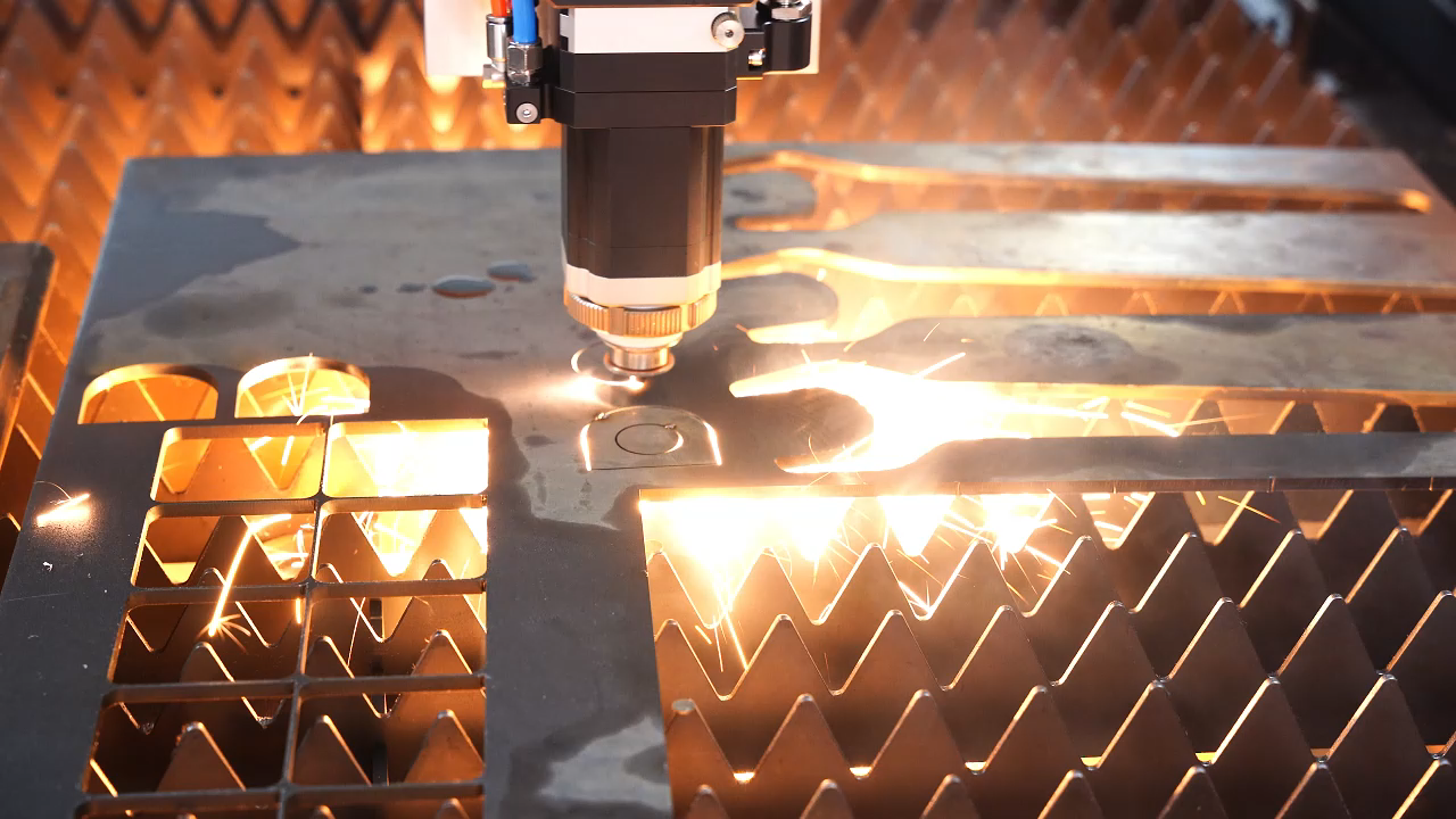

Optimal cutting performance hinges on balancing three key parameters:

- Power (1-20 kW): Higher wattages enable thicker material processing but increase energy costs

- Speed (0-50 m/min): Thin sheets (<10mm) can be cut at over 30 m/min without sacrificing quality

- Spot size (10-100µm): Smaller diameters (<30µm) improve edge finish but require precise beam alignment

AI-assisted systems that dynamically adjust these parameters deliver 18-22% higher throughput, according to the 2024 Laser Processing Survey.

Material Thickness Limits for Fiber Laser Cutting in Industrial Applications

Modern fiber lasers handle a wide range of industrial materials:

- Carbon steel: 0.5-40mm (1kW-20kW systems)

- Stainless steel: 0.3-30mm with nitrogen assist gas

- Aluminum alloys: 0.5-25mm using pulse modulation

Notably, 6kW systems now cut 25mm stainless steel at 1.2m/min—300% faster than 2019 benchmarks—demonstrating rapid advancements in capability.

Heat-Affected Zone (HAZ) and Thermal Damage in Conductive Metals

Fiber lasers can cut down on HAZ width by around 60 to 80 percent when compared with traditional CO2 systems. This makes them really important for making aerospace parts where even small amounts of heat damage matter a lot. When using pulsed mode settings, the temperature stays under 350 degrees Celsius for stainless steel materials. This helps maintain the metal's structural properties without compromising quality. Take 304L stainless steel as an example. Cutting it with a 3 kilowatt fiber laser results in only about 0.08 millimeters of HAZ, whereas older CO2 laser technology would leave behind roughly 0.25 millimeters worth of heat affected zone. These differences might seem tiny but they make all the difference in precision manufacturing applications.

Comparative Advantage of Fiber Lasers Over CO2 Lasers in Metal Cutting

Fiber lasers outperform CO2 lasers in three major areas:

- Operational costs: 70% lower energy consumption per cut

- Maintenance: No mirrors to align, reducing downtime by 45%

- Thin material speed: 4-6x faster on sheets under 6mm

For sheet metal operations, this translates to $18-22/hr cost savings on 6kW systems processing mild steel (2024 Metalworking Efficiency Study).

Carbon Steel and Stainless Steel: Core Industrial Applications

Why Carbon Steel Responds Well to Fiber Laser Energy

The carbon content in steel between 0.05% and 2.1% means it absorbs the 1,070 nm fiber laser wavelength really well. Most other metals just reflect away most of that energy, but carbon steel actually puts about 95% of what hits it right into the cutting process. That's why we can cut through 1 mm thick sheets at around 40 meters per minute, which is pretty fast for industrial applications. The material works great for things like car frames and building structures where precision matters. Another big plus is that fiber lasers consume roughly 30% less power than traditional plasma cutting methods when working with carbon steel pieces thinner than 20 mm thick. This energy savings adds up over time in manufacturing operations.

Optimal Laser Settings for Mild and High-Carbon Steel Cutting

| Parameter | Mild Steel (0.1-0.3% C) | High-Carbon Steel (0.6-1.0% C) |

|---|---|---|

| Power (W) | 2,000-3,000 | 3,500-4,500 |

| Speed (m/min) | 6-10 (for 6 mm) | 2.5-4 (for 6 mm) |

| Assist Gas | Oxygen (oxidizing) | Nitrogen (non-reactive) |

High-carbon steels require higher power due to increased hardness, while oxygen assist accelerates mild steel cutting through exothermic reactions. Nitrogen reduces edge oxidation by 72% in tool steels, maintaining post-cut machinability, as shown in a 2023 industrial study.

Precision Cutting of Stainless Steel While Preserving Corrosion Resistance

Fiber lasers achieve kerf widths under 0.1 mm, minimizing waste in medical and food processing equipment. Their ultra-short pulse durations (<0.5 ms) prevent chromium depletion at cut edges, preserving the 10.5% chromium threshold essential for corrosion resistance. Testing confirms laser-cut 304L stainless retains 98% of its salt-spray resistance compared to sheared parts.

Minimizing HAZ in Austenitic and Martensitic Stainless Steel Grades

Pulsed fiber lasers limit HAZ to <50 µm in sensitive 316L austenitic steel by cycling between 20-50 kHz frequencies. For martensitic grades like 410, the narrow thermal impact simplifies post-cut tempering (150-370°C), restoring ductility. A 2024 analysis found fiber lasers reduce HAZ-related scrap rates by 19% versus CO2 lasers in aerospace production.

Cutting Aluminum and Other Reflective Non-Ferrous Metals

Challenges of Processing Aluminum With Fiber Laser Cutting Machine Due to Reflectivity

The combination of aluminum's near total reflectivity at around 95% plus its impressive thermal conductivity (over 200 W/m K) creates real headaches for manufacturers. Although fiber lasers operating at 1 micron wavelength help reduce reflections compared to traditional CO2 systems, those super smooth surfaces found in aerospace grade materials can still bounce back enough energy to wreak havoc on optical components. Getting a cut started takes roughly 20 to 30 percent more power density than what's needed for steel because aluminum sheds heat so quickly. Processing pure aluminum grades like the 1100 series proves far trickier than working with tempered options such as 6061 T6 alloy. These tempered variants actually absorb laser beams better and produce significantly less dross during cutting operations according to most fabrication shops we've spoken to recently.

Pulse Modulation and Assist Gas Strategies for Clean, Reliable Aluminum Cuts

When it comes to working with aluminum sheets between 1 and 8 mm thick, adaptive pulse shaping makes a real difference. Especially when using burst mode pulsing around 1 to 5 kHz, this technique gives better control over the melt pool. Edge rippling drops by about 18 percent compared to just running continuous waves according to research published in Material Processing Journal last year. For parts that need to stand up to harsh environments, like those used in boats or cars, adding nitrogen assist gas at pressures between 15 and 20 bar works wonders. It stops oxides from forming while pushing out molten material effectively. Some manufacturers are now combining nitrogen cutting with oxygen edge sealing in their dual gas systems. This approach has actually sped things up by roughly 12 percent in battery tray production lines, which matters a lot given how fast demand is growing for electric vehicle components.

Can Fiber Lasers Cut Thick Aluminum? Addressing Industry Skepticism

The latest developments have made it possible for fiber lasers to slice through aluminum that's as thick as 25mm, going well beyond what was previously considered practical at around 15mm. Take a 12kW setup equipped with those fancy dynamic beam oscillations, and it can handle 20mm thick 5083 marine grade aluminum at about 0.8 meters per minute while maintaining a precision range of plus or minus 0.1mm. That kind of performance used to be something only plasma cutting could achieve. But when working with materials thicker than 12mm, operators need to adjust their approach using oscillation patterns between 40 and 50 microns to avoid unwanted tapering effects. This adjustment comes at a cost though, since gas usage goes up by roughly 35%. For anything over 30mm thick plates, CO2 lasers are still king of the hill. However, for most industrial applications dealing with aluminum below 20mm thickness, fiber laser systems currently cover about four out of five processing requirements across various manufacturing sectors.

High-Performance Alloys: Titanium and Inconel in Demanding Industries

Fiber Laser Cutting Machine Material Compatibility with Titanium and Inconel

When it comes to working with tough materials like titanium and those nickel based superalloys we call Inconel, fiber lasers really shine thanks to their special 1.08 micrometer wavelength. These materials actually soak up this kind of laser light about 47 percent better than they do CO2 laser beams, making the process much more efficient overall. Speaking of efficiency, titanium isn't great at conducting heat (only around 7.2 watts per meter Kelvin), so the laser can deliver its energy right where needed without spreading out too much. And for Inconel parts, there's another advantage when cutting them with nitrogen as a protective gas cover. The material stays resistant to oxidation during the process, which means cleaner cuts and fewer quality issues down the line.

Managing Thermal Stress During Titanium Laser Cutting

Controlled pulse modulation reduces thermal stress in aerospace-grade titanium by 25%, preventing microcracking in critical components. Advanced systems use <8 ms pulses with oxygen-free assist gases to keep temperatures below 400°C, preserving fatigue resistance above 750 MPa—essential for medical implants and turbine blades.

Case Study: Precision Cutting of Inconel 718 for Aerospace Jet Engine Components

A 6 kW fiber laser achieved ±0.05 mm tolerances cutting Inconel 718 combustor liners at 4.2 m/min, as detailed in a 2024 Springer Materials Science study. The nitrogen-assisted process prevented sigma phase precipitation, preserving creep resistance at 980°C and meeting aerospace AS9100 quality standards.

Advancements Enabling Thicker High-Performance Alloy Processing

Breakthroughs in collimator optics and gas dynamics now allow fiber lasers to cut 25 mm titanium plates at 0.8 m/min with <0.3 mm kerf—rivaling plasma speeds while achieving Ra 12.5 µm surface finishes. Dynamic focal length adjustment compensates for material stratification in multi-layer aerospace parts, expanding feasible applications by 35% since 2022.

Future Trends: Expanding the Boundaries of Fiber Laser Material Processing

Emerging Applications Beyond Traditional Metals

Fiber lasers have become essential tools for working with all sorts of tough materials these days. They handle advanced composites, those tricky ceramic-metal combinations, and even layered structures needed for thermal protection systems in aircraft. What really stands out is how they can slice through carbon fiber reinforced plastics while leaving behind a heat affected zone of just under 0.1mm. This level of precision is exactly what manufacturers need when making battery casings for the latest generation of electric vehicles. Looking ahead, most industry observers expect around 18 percent yearly increase in fiber laser usage for additive manufacturing right up until 2033. The main driver here seems to be growing interest in printing complex parts from titanium using 3D printing technology across various sectors.

Hybrid Material Processing in Advanced Manufacturing

Manufacturers are integrating fiber lasers with robotic welding and cladding systems to create single-machine production cells. A 2023 analysis found hybrid systems reduce multi-material assembly costs by 34%. This integration enables simultaneous cutting of aluminum heat sinks and welding of copper busbars in power electronics—tasks previously requiring three separate processes.

Smart Parameter Adaptation for Multi-Material Production Lines

Fiber lasers powered by artificial intelligence can automatically tweak their power output between 2 kW to 12 kW and manage assist gas pressures ranging from about 15 to 25 bar whenever different materials come into play. Systems connected through the Internet of Things cut down on waste significantly during tests last year, slashing scrap rates by around 41%. This was possible because these smart systems spotted changes in material thickness as they happened. When it comes to cutting paths on sheets made from various materials, machine learning algorithms do a much better job than traditional methods. Automotive manufacturers report getting nearly 98% material usage from their chassis parts, which beats what standard nesting software could achieve by roughly 22 percentage points according to industry reports.

FAQ Section

What makes fiber laser cutting machines more efficient than CO2 lasers?

Fiber lasers are up to 95% efficient at converting electricity to light energy, which is almost double the efficiency of older CO2 laser technology. This results in faster cutting speeds and lower operational costs.

Can fiber lasers cut materials thicker than 20mm?

Yes, recent advancements allow fiber lasers to cut materials as thick as 25mm, especially in aluminum and titanium, making them suitable for a wide range of industrial applications.

How do fiber lasers minimize the heat-affected zone?

Fiber lasers reduce the width of the heat-affected zone by up to 80% compared to CO2 lasers, crucial for precision in applications such as aerospace manufacturing.

Are fiber lasers suitable for cutting aluminum?

Fiber lasers can effectively cut aluminum, especially tempered alloys, using adaptive pulse modulation and nitrogen assist gas strategies to minimize reflections and thermal damage.

Table of Contents

-

How Fiber Laser Cutting Machines Excel in Metal Processing

- Understanding Fiber Laser Cutting Machines and Their Dominance in Metal Fabrication

- Laser Parameters Affecting Cutting Efficiency and Quality: Power, Speed, and Spot Size

- Material Thickness Limits for Fiber Laser Cutting in Industrial Applications

- Heat-Affected Zone (HAZ) and Thermal Damage in Conductive Metals

- Comparative Advantage of Fiber Lasers Over CO2 Lasers in Metal Cutting

- Carbon Steel and Stainless Steel: Core Industrial Applications

- Cutting Aluminum and Other Reflective Non-Ferrous Metals

-

High-Performance Alloys: Titanium and Inconel in Demanding Industries

- Fiber Laser Cutting Machine Material Compatibility with Titanium and Inconel

- Managing Thermal Stress During Titanium Laser Cutting

- Case Study: Precision Cutting of Inconel 718 for Aerospace Jet Engine Components

- Advancements Enabling Thicker High-Performance Alloy Processing

- Future Trends: Expanding the Boundaries of Fiber Laser Material Processing

- Emerging Applications Beyond Traditional Metals

- Hybrid Material Processing in Advanced Manufacturing

- Smart Parameter Adaptation for Multi-Material Production Lines

- FAQ Section