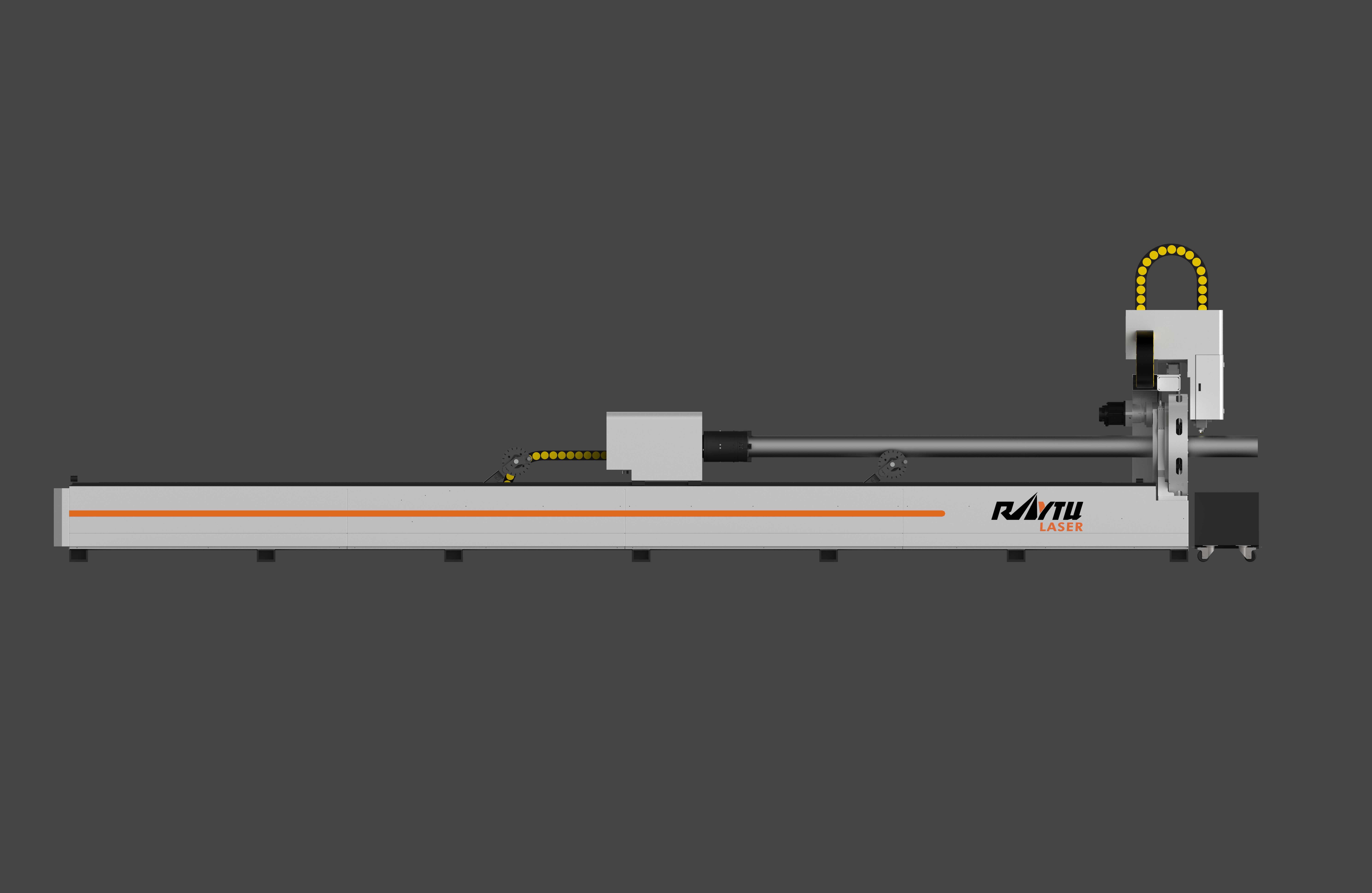

Precision and Accuracy in Tube Cutting with Fiber Laser Technology

How Fiber Laser Tube Cutting Technology Enhances Precision and Accuracy

Today's pipe laser cutters can hit about plus or minus 0.05 mm accuracy thanks to those 1064 nm fiber lasers that pack all their power into just a 0.1 mm beam. The intense heat they deliver actually helps reduce warping problems, so even when working with super thin stainless steel pipes down to 0.5 mm walls, the results stay nice and clean without excessive melting around the edges. What really sets these systems apart though is their real time seam tracking feature. While the machine is running, it constantly adjusts where it cuts based on what it sees through its cameras. This beats out old school mechanical approaches hands down since those tend to lose accuracy as tools get worn down after repeated use, something laser systems just don't have to worry about.

Tolerance Levels and Surface Finish Quality in Stainless Steel and Aluminum Tubes

Fiber lasers can hold dimensional tolerances around 0.1 mm across different materials, producing surface roughness at about Ra 1.6 microns on 304 stainless steel tubes with walls between 1 and 6 mm thick, all without needing any extra finishing work afterward. When working with aluminum alloys, the system adjusts gas pressure automatically which cuts down those pesky oxidation streaks by roughly 60 percent when compared to older CO2 laser technology, resulting in Ra 3.2 micron finishes good enough for structural parts. A recent look at manufacturing data from last year showed that these kinds of improvements actually save around eight dollars fifty cents per meter on deburring costs specifically in automotive exhaust production lines.

Comparison of CO2 vs. Fiber Laser Accuracy in Thin-Walled Tube Cutting

| Parameter | Fiber Laser | CO2 Laser |

|---|---|---|

| Minimum Wall Thickness | 0.3 mm | 0.8 mm |

| Cut Speed (2mm SS) | 12 m/min | 5 m/min |

| Heat-Affected Zone | 0.2–0.5 mm | 1.2–2.0 mm |

| Angular Accuracy | ±0.1° | ±0.3° |

Fiber systems offer 3– better energy efficiency and achieve 40% faster kerf closure in galvanized steel tubing, making them superior for high-precision, thin-walled applications.

Case Study: Reducing Scrap Rates by 35% Using Closed-Loop Feedback Systems

One metal fabrication shop recently upgraded to a fiber laser cutting setup that includes machine vision checks, which cut down on stainless steel waste quite a bit—from around 8.2% down to just 5.3% each year according to last year's Industrial Laser Report. What makes this system special is how it samples at an impressive rate of 500 times per second. This allows it to spot tiny differences in tube diameters measured in microns and then tweak things like feed speed and laser intensity accordingly. The result? A pretty significant savings story too. We're talking about nearly seven hundred forty thousand dollars saved yearly on materials alone, all without compromising quality since everything still meets those tough ASME BPE-2022 specs required for parts used in fluid systems.

Material Compatibility and Thickness Range for Pipe Laser Cutting Machines

Modern pipe laser cutting machines handle steel, aluminum, and stainless steel tubes with high precision. Fiber lasers cut carbon steel up to 30 mm thick and stainless steel up to 20 mm, though optimal performance for non-ferrous metals like aluminum typically extends to 15 mm (roboticsandautomationnews.com, 2024).

Laser Cutting Performance Across Steel, Aluminum, and Stainless Steel Tubes

When it comes to fiber laser cutting, steel tubes work really well because they don't reflect much light back at the machine. Even when dealing with fairly thick material around 12 mm, these cuts can be pretty narrow too – sometimes below half a millimeter wide. Things get trickier with aluminum though since it conducts heat so quickly. Operators need to constantly adjust the laser power otherwise the edges just melt away instead of getting clean cuts. The good news is technology has improved quite a bit lately. Modern fiber lasers can now handle aluminum tubes as thick as 8 mm while moving along at over 12 meters per minute. What's impressive is how straight those cuts stay despite all that speed, typically staying within 0.2 mm tolerance which makes a big difference in manufacturing quality.

Thermal Conductivity Challenges in Non-Ferrous Metals and Adaptive Power Control

To counteract aluminum’s rapid heat dissipation, fiber laser systems use real-time energy modulation. Adjusting pulse duration (5–20 ms) and dynamic gas pressure (2–4 bar) enables clean cuts in reflective materials like copper alloys and polished aluminum, which previously resulted in scrap rates as high as 18%.

Optimizing Cut Quality for Material Thicknesses From 0.5 to 12 mm

| Thickness Range | Speed Adjustment | Assist Gas Pressure | Edge Quality (Ra) |

|---|---|---|---|

| 0.5–2 mm | 20–25 m/min | 8–10 bar (Nitrogen) | 1.6–2.5 μm |

| 2–6 mm | 12–18 m/min | 6–8 bar (Oxygen) | 3.2–4.0 μm |

| 6–12 mm | 4–8 m/min | 4–6 bar (Argon) | 5.0–6.3 μm |

Closed-loop monitoring automatically adjusts 14 parameters to maintain ±0.1 mm dimensional accuracy across this range, allowing a single machine to process 95% of common industrial tubing applications.

Automation and CNC Integration for Efficient Tube Processing

Modern pipe laser cutting machines maximize efficiency through automated material handling and CNC system integration. Facilities using robotic loaders and AI-driven controls reduce idle time by 52% while maintaining ±0.1 mm positional accuracy (2024 industry analysis).

Automation Features: Automatic Loading, Unloading, and Robotic Material Handling

Robotic arms transfer tubes up to 12 meters long between storage and cutting stations with adaptive gripping technology, preventing surface damage on stainless steel and aluminum profiles. This automation reduces manual handling, improves safety, and ensures consistent part positioning.

Integration with CAD/CAM Software for Seamless Design-to-Production Workflow

Advanced systems convert 3D CAD models into machine instructions in under 90 seconds, eliminating manual programming errors. Nesting algorithms optimize material usage, achieving 92–95% utilization rates—especially beneficial for high-cost alloys.

Real-Time Monitoring and Error Correction Using AI-Driven CNC Control Systems

Machine vision and thermal sensors detect deviations such as focal point drift or gas pressure fluctuations, triggering micro-adjustments within 0.3 seconds. This closed-loop correction ensures defect-free cutting of thin-walled (0.8–1.5 mm) titanium tubes used in aerospace components.

Case Study: 40% Increase in Throughput with Integrated Automation

A leading manufacturer replaced legacy equipment with a fully automated pipe laser cutting system featuring robotic unloading and cloud-connected CNC controls. Cycle time dropped from 18 to 10 minutes per part, and scrap rates fell by 29% (MetalForming Journal 2024), significantly boosting throughput and cost efficiency.

Multi-Axis Flexibility and Complex Geometry Cutting Capabilities

Today's pipe laser cutters can achieve around 0.1 degree accuracy thanks to their advanced 5 axis systems which include rotating heads, multiple turning points, and smart focus adjustments. These features make it possible to create complex shapes, angled edges, and intricate three dimensional patterns on pipes as big as 300 millimeters across. For industries where tight tolerances matter most this capability is absolutely critical. Think about aircraft fuel lines that need completely sealed connections or car exhaust systems where even the smallest leak could cause problems down the road. Manufacturers rely on these machines because they simply cannot afford mistakes when dealing with such demanding applications.

Cutting Complex Profiles with 3D Multi-Axis Motion and Rotary Axis Precision (±0.1°)

CNC controls synchronize the laser head’s X-Y-Z movements with the tube’s rotational (C-axis) and tilt (A-axis) motions, maintaining optimal focal distance even on curved surfaces. This eliminates manual repositioning and reduces ovality errors by up to 70% in thin-walled hydraulic tubing compared to 3-axis systems.

Applications in Automotive Exhausts, Aerospace, and Construction Tubing

- Automotive: 45° miter cuts on stainless steel exhaust manifolds with 0.2 mm gap tolerance

- Aerospace: 3D slots in titanium landing gear tubes for weight reduction

- Construction: Notching structural steel columns for earthquake-resistant frameworks

Growing Demand for Mitered Joints and Contour Cuts in Industrial Fabrication

The shift toward modular assembly has increased demand for pre-notched tubes ready for welding. Six-axis pipe laser cutting machines reduce post-processing labor by 50%, and manufacturers report 30% less material waste when nesting complex parts like HVAC duct elbows compared to plasma cutting.

Dual Functionality and System Scalability in Modern Pipe Laser Cutting Machines

Today's pipe laser cutting machines are getting pretty smart, combining two different processing methods in one unit while still being able to scale up or down depending on what the shop needs. The latest models can handle both flat sheets and round tubes right on the same machine, which cuts down significantly on equipment expenses for shops that deal with all sorts of materials. These hybrid systems come with interchangeable parts and special lenses that adjust automatically, keeping measurements accurate within about 0.1 millimeters whether working on flat metal or round pipes. Shops report they finish jobs around 30 percent quicker compared to older setups where separate machines were needed for each type of material.

Space and Cost Efficiency for Job Shops with Mixed Production Needs

Manufacturers of smaller to medium size can save valuable floor space with these machines. A single 15 kW unit takes up about 35% less room compared to having both plate and tube cutting equipment separately. According to Laser Systems Journal from last year, this kind of setup cuts down on energy usage by around 18%. Plus, workers don't have to switch tools when moving between flat sheets and round tubes during production runs. Most job shops we've talked to see their return on investment happen pretty quickly too. About 7 out of 10 report getting their money back within just over a year because they spend less time doing extra work steps and moving materials around the shop floor.

Modular Bed Designs and Support for Tubes Up to 300mm Diameter and 6+ Meters

Scalable systems feature:

- Interchangeable clamping modules for round, square, and rectangular profiles

- Dynamic power modulation for stainless steel thicknesses from 0.5–12 mm

- Linear motor drives ensuring 0.02 mm/m positioning accuracy over 6-meter spans

This flexibility allows processing of HVAC ducts and structural columns on the same platform, with adaptive nesting software reducing material waste by 22% in mixed-load production. The modular design future-proofs operations, supporting capacity upgrades without full system replacement.

FAQ

What is the advantage of using fiber laser over CO2 laser for tube cutting?

Fiber lasers provide higher accuracy, especially in thin-walled tube cutting, due to better energy efficiency and faster kerf closure. They are also more effective in producing cleaner cuts for reflective materials like aluminum.

How do fiber lasers enhance material utilization in manufacturing?

Fiber laser systems use nesting algorithms and machine vision checks to optimize material usage, resulting in reduced waste and increased material utilization rates.

Can a single fiber laser cutter handle different materials and thicknesses?

Yes, modern fiber laser cutters are equipped to process a range of materials such as steel, aluminum, and stainless steel with varying thicknesses, typically handling up to 30 mm for carbon steel and up to 15 mm for aluminum.

What role does automation play in modern fiber laser cutting machines?

Automation significantly enhances efficiency by reducing manual handling and improving safety. Robotic arms and AI-driven controls assist in precise part positioning and real-time error correction, minimizing idle time and scrap rates.

How does fiber laser technology address heat dissipation issues in non-ferrous metals?

Fiber lasers utilize real-time energy modulation and adjust parameters like pulse duration and gas pressure to manage rapid heat dissipation in materials like aluminum and copper, ensuring clean cuts.

Table of Contents

- Precision and Accuracy in Tube Cutting with Fiber Laser Technology

- Material Compatibility and Thickness Range for Pipe Laser Cutting Machines

-

Automation and CNC Integration for Efficient Tube Processing

- Automation Features: Automatic Loading, Unloading, and Robotic Material Handling

- Integration with CAD/CAM Software for Seamless Design-to-Production Workflow

- Real-Time Monitoring and Error Correction Using AI-Driven CNC Control Systems

- Case Study: 40% Increase in Throughput with Integrated Automation

- Multi-Axis Flexibility and Complex Geometry Cutting Capabilities

- Dual Functionality and System Scalability in Modern Pipe Laser Cutting Machines

-

FAQ

- What is the advantage of using fiber laser over CO2 laser for tube cutting?

- How do fiber lasers enhance material utilization in manufacturing?

- Can a single fiber laser cutter handle different materials and thicknesses?

- What role does automation play in modern fiber laser cutting machines?

- How does fiber laser technology address heat dissipation issues in non-ferrous metals?