Laser Power, Speed, and Focus Control

How Laser Power Influences Material Penetration and Edge Quality

The amount of laser power basically controls how much energy gets concentrated on the material, which then affects how deep it cuts and how smooth those edges end up being. When working with thinner stuff, say around 0.5mm stainless steel, keeping the power low between 300 to 500 watts helps avoid unwanted warping. But these lower settings just don't work well when dealing with anything thicker than about 3mm. Move all the way up to 4000 watts plus and CO2 lasers start making serious progress through 25mm carbon steel sheets. However there's a catch here too since such high power tends to create those pesky heat affected zones measuring roughly 80 to 120 micrometers wide. The latest numbers from the 2023 Industrial Laser Report show that getting laser power right within about ten percent of what's needed for different material thicknesses actually boosts cutting accuracy by nearly seventeen percent overall.

Balancing Cutting Speed With Precision and Kerf Width Control

Cutting at high speeds over 25 meters per minute helps cut down on heat damage but can actually make the cut width vary more in copper alloys sometimes by as much as 12%. When going slower than 5 meters per minute though, we get much better control with around plus or minus 0.05 millimeters accuracy for 5 mm thick aluminum parts, although this takes three times longer to process. Today's advanced machines have smart speed adjustments ranging from half a meter to two meters per second depending on what the infrared sensors detect in real time. This lets manufacturers maintain good quality cuts while still keeping production moving efficiently through their shops.

The Role of Focus Position in Beam Density and Cutting Accuracy

Small changes in focus, even just plus or minus 0.1mm, can cut down beam density by almost 40% when working with fiber lasers. Getting the focal point right makes a big difference too. When cutting through 10mm acrylic, proper positioning brings those pesky melt ejections down from around 85 microns to about 25 microns. Research published last year in the International Journal of Advanced Manufacturing showed something interesting as well. Shifts between 0.8 and 1.2mm in focal position on galvanized steel actually change the kerf angle by 5 to 7 degrees. That might not sound like much until you're trying to fabricate automotive panels where getting those angles exactly right matters a lot for fit and finish.

Interdependence of Power, Speed, and Focus in High-Precision Operations

Precision cutting requires synchronized control of power, speed, and focus:

- Doubling laser power (2000W → 4000W) requires 18-22% focus compensation

- A 15m/min speed increase demands 25-30W power adjustment to maintain 0.1mm accuracy

- Focus shifts beyond 0.25mm necessitate 12% speed reduction to keep surface roughness at Ra ≤1.6μm

These parameters interact nonlinearly, prompting 92% of industrial systems to adopt AI-driven predictive models for real-time optimization.

Material Properties and Their Impact on Cutting Accuracy

Variations in accuracy across metals, plastics, and composites

What kind of material we're working with makes a big difference when it comes to how accurately something can be cut. Stainless steel stands out for its tight tolerances ranging from plus or minus 0.002 to 0.005 inches, which beats aluminum by about 70%. This happens because stainless absorbs heat more evenly during processing. On the flip side, aluminum isn't as good since it reflects light and is softer, leading to tolerances around 0.006 inches. Plastics present another challenge altogether with their tolerance range between 0.008 and 0.012 inches mainly due to warping from heat exposure. Interestingly enough, this issue gets somewhat controlled using pulse modulation techniques. When looking at composites, these materials tend to have about 23% more variation in cut width compared to regular single-material substances. The reason? Their layered construction doesn't react uniformly to laser beams, creating inconsistencies in the final product.

Challenges in precision when cutting thick or highly reflective materials

When working with steel that's half an inch thick, beam dispersion actually cuts down on edge perpendicularity by around 40% when compared to quarter inch sheets. This is quite a difference for manufacturers to consider. Now take highly reflective materials such as copper which reflects about 95 percent of light at one micrometer wavelength. These properties cause the metal to bounce back a lot of laser energy during processing. Because of this reflection problem, operators need to slow things down by roughly 25% just to keep within those tight tolerances of plus or minus 0.004 inches for positioning accuracy. Fortunately there are ways around these challenges today. Many modern cutting systems now incorporate what we call adaptive optics technology along with special dual pressure gas assistance configurations. These innovations help maintain consistent cut quality even when dealing with tricky materials that would otherwise create problems for standard equipment setups.

Thermal conductivity and reflectivity: hidden contributors to inaccuracy

When working with materials that conduct heat really well like silver or copper which have thermal conductivity ratings above 300 W/mK, they tend to lose laser energy about 15 percent quicker compared to stainless steel. This creates problems during processing since we end up with uneven melt pools and sometimes see kerf expansion reaching as much as 0.0015 inches. The situation gets even trickier when dealing with polished metal surfaces because their reflectivity ranges between 80 to nearly 98 percent, bouncing back around 30 to 40 percent of whatever laser beam hits them. That's why modern equipment now comes equipped with closed loop monitoring systems that constantly tweak the power levels being delivered. These adjustments help maintain those critical micron level tolerances despite all these complications in material response and surface characteristics.

CNC and Motion Control Systems in Precision Laser Cutting

How CNC Systems Enable Micron-Level Positioning Accuracy

Computer Numerical Control (CNC) systems play a key role in getting those super precise cuts we need these days. These machines can turn digital blueprints into actual parts with tolerances down to around 5 microns, meeting the requirements set out in ISO 9013:2017 standards. What makes them so reliable is that they cut out the possibility of human mistakes while following programmed paths for cutting tools, which means manufacturers get consistent results even when running at top speed. The multi-axis controllers work behind the scenes to keep everything synchronized between where the laser head moves and how fast material gets fed through, fine tuning acceleration settings to prevent unwanted vibrations during operation. Recent research from MIT's robotics department back in 2022 found something interesting too - their tests revealed that closed loop systems actually cut down on variations in kerf width by about 34% compared to older open loop configurations when working with tough aerospace materials.

Servo vs. Stepper Motors and Closed-Loop vs. Open-Loop Control Debates

Servo motors without brushes that come with those fancy 20-bit rotary encoders can measure angles as small as 0.0003 degrees, which means they're capable of positioning things at the micron level. These motors pack about three times more torque per unit volume compared to regular stepper motors, so they can speed up really fast without losing their place during operation something that matters a lot when making detailed cuts through tough stuff like stainless steel. With closed loop systems, the motor keeps checking where it actually is against where it should be based on encoder readings, then fixes any mistakes instantly to stay within less than 0.01 millimeters of accuracy. Around a quarter of manufacturers are still going with open loop steppers mainly because they save money on projects involving mild steel, but most folks in the business are moving toward these closed loop servos especially when working with tricky metals such as copper or titanium where precision counts.

Software Path Planning and Interpolation Effects on Cut Fidelity

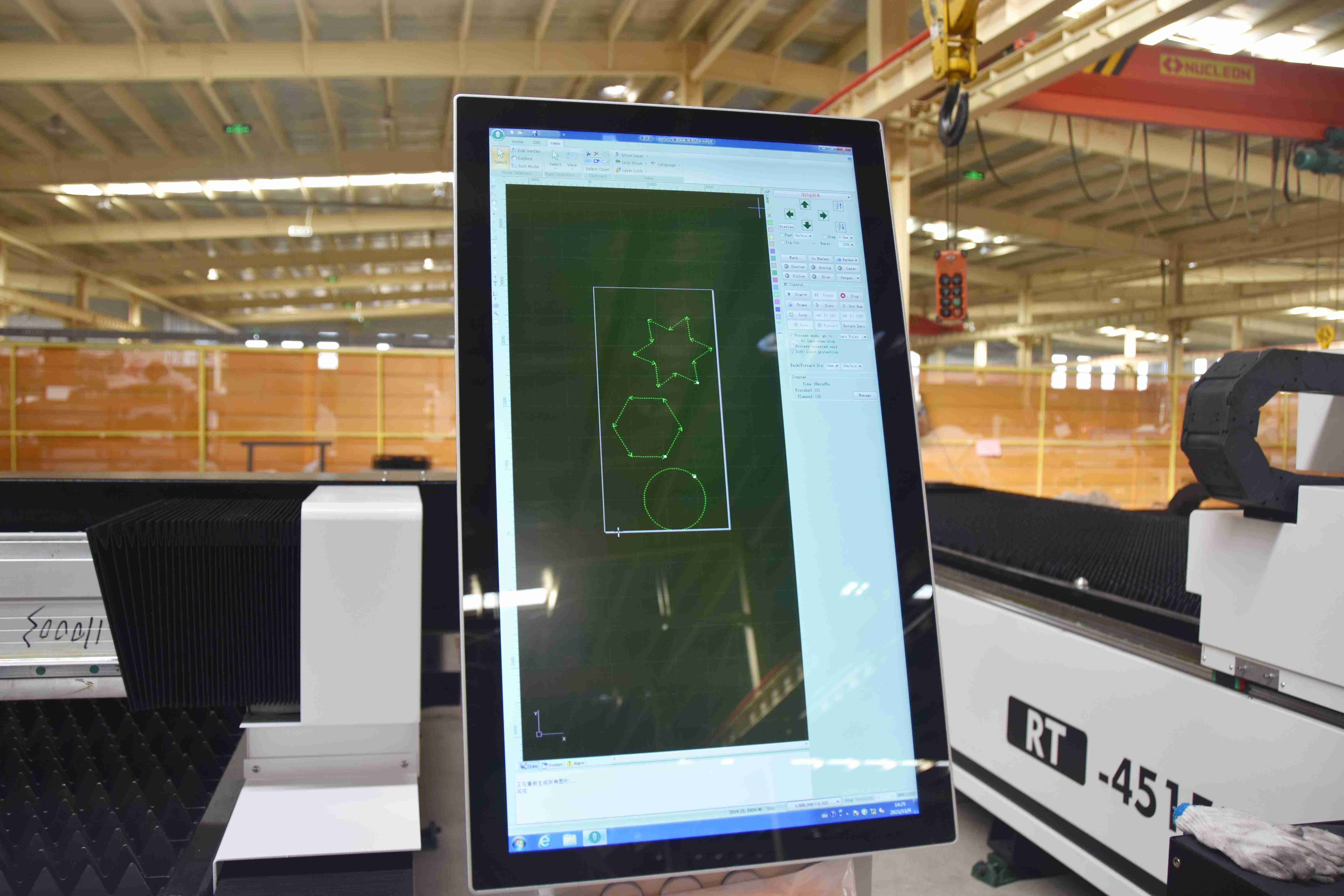

The quality of cuts really depends on good CAM software these days. When it comes to interpolation techniques, NURBS gives much smoother toolpaths compared to those old linear or circular approaches. Some tests showed this can cut down angular errors by around two thirds when working with complex organic shapes, something mentioned in that recent 2024 CAD/CAM Almanac report. Another important feature is look ahead processing which checks out over 500 motion commands before execution. This helps adjust speeds so we don't get those annoying undercuts whenever the tool changes direction suddenly. For medical parts where precision matters a lot (think below 0.1mm tolerances), the system will automatically slow down the cutting head as it goes through tight curves. And let's not forget about those specialized post processors either. They account for how each specific machine behaves in real world conditions, making sure what actually gets cut matches what was programmed down to about 5 microns difference.

Critical Machine Components Influencing Accuracy

Precision in laser cutting depends on the harmonious operation of three core subsystems: the laser source, beam delivery components, and assist gas mechanisms. Proper calibration and maintenance of these systems enable ±0.05 mm tolerances in industrial settings (Ponemon Institute, 2023).

Laser Source Stability and Beam Quality (M² Factor)

A stable laser source maintains less than 15% power fluctuation, ensuring consistent penetration and edge finish. The M² factor measures beam focusability, with values below 1.3 ideal for narrow kerfs. Machines with M² >2.0 suffer up to 30% wider heat-affected zones, compromising accuracy in thin stainless steel.

Optics Alignment, Lens Condition, and Kerf Consistency

| Component | Impact on Accuracy | Maintenance Interval |

|---|---|---|

| Collimation Lenses | Beam focus ±0.1 mm deviation | 500 operating hours |

| Nozzle Condition | 20–35% kerf width variation if worn | 200 cuts |

Dust on mirrors reduces beam intensity by 12-18%, while misaligned optics cause focal shifts equivalent to 0.25% of material thickness. Automated pressure sensors now alert operators to lens contamination before accuracy degrades beyond acceptable limits.

Assist Gas Purity, Pressure, and Their Effect on Dross and Smoothness

High-purity assist gases (>99.95%) prevent oxidation-related edge defects, especially in non-ferrous metals. Optimal pressure varies by material:

- Aluminum: 12–15 bar nitrogen reduces dross by 40% versus compressed air

- Carbon Steel: 1.2–1.5 bar oxygen delivers clean cuts but requires ±0.05 bar precision

Insufficient gas flow increases recast layer thickness by up to 25 µm, often requiring secondary finishing. Real-time gas monitoring has reduced cutting head clogs by 78% in high-volume production environments.

Machine Maintenance and Environmental Stability

Structural Rigidity and Machine Bed Stability as Accuracy Foundations

Machine structural integrity is foundational to long-term precision. Units with reinforced granite bases or polymer-composite frames exhibit 40% less vibrational distortion than standard models, maintaining ±0.01 mm accuracy during high-speed operation. Proper leveling and anchoring prevent micro-movements, while corrosion-resistant materials resist warping from thermal changes.

Routine Maintenance to Prevent Optical and Mechanical Degradation

Cleaning laser optics on a weekly basis keeps around 98% of the beam's power intact, something that makes all the difference when it comes to getting uniform cuts with clean edges. For monthly maintenance, running interferometry checks helps spot tiny misalignments down to 0.1 degrees before they turn into serious problems like 0.15 mm cutting inaccuracies across the workpiece. When shops properly lubricate those linear guides and ball screws, they cut down on positioning drift caused by friction by about two thirds. Shops adopting predictive maintenance approaches that mix vibration monitoring with thermal imaging reports have seen their unplanned machine stoppages drop by roughly one third over time, industry research shows. These improvements translate directly into better productivity numbers for manufacturing operations.

Temperature, Vibration, and Humidity: Managing External Accuracy Risks

When ambient temperatures swing more than 2 degrees Celsius above or below target, steel parts expand thermally, which can throw off positioning by as much as 0.02 millimeters for each degree change. To combat this issue, modern facilities install vibration damping bases along with active isolation tech that cuts down on floor vibrations by around 85%. Keeping humidity under 60% relative humidity stops moisture from forming on sensitive optical equipment and electronic components. The air filtration system plays another important role too, making sure the assist gases stay clean enough so nozzles don't get clogged and laser beams don't scatter during operation.

FAQ Section

What is the impact of laser power on cutting accuracy?

Laser power determines the energy concentration on the material, affecting both penetration depth and edge quality. Properly adjusting power according to material thickness can result in increased cutting accuracy.

How does cutting speed affect precision?

Cutting speed influences kerf width. Higher speeds can lead to wider variances in cut width, while slower speeds offer greater precision but require more processing time.

Why is focus position crucial in laser cutting?

Focus position impacts beam density and cutting accuracy. Adjusting the focal point can reduce melt ejections and change kerf angles, which are critical in applications needing precise fits.

How do material properties affect laser cutting?

Material properties like reflectivity and thermal conductivity significantly influence cutting precision. Metals, plastics, and composites each react differently to laser beams, affecting tolerance levels.

What role does CNC play in laser cutting accuracy?

CNC systems facilitate micron-level positioning by converting digital blueprints into precise movements, minimizing human error and increasing consistency.