Common Pipe Materials Compatible with Pipe Laser Cutting Machines

Modern pipe laser cutting machines are engineered to process a wide range of materials essential across industries such as construction, automotive, and aerospace. Their ability to deliver high precision on diverse metals ensures reliable performance in demanding fabrication environments.

Carbon Steel and Stainless Steel: Industrial Standards for Precision Cutting

Carbon steel remains popular for structural work because it combines decent strength with reasonable costs and predictable results when cut with lasers. Stainless steel gets chosen often in places where rust is a problem, especially in food plants, hospitals, and factories handling chemicals. The newer fiber laser tech can get down to about 0.1 mm precision on these metals, which cuts down those pesky heat affected areas by roughly 30% compared to older CO2 laser systems. Manufacturers now produce thousands of parts daily thanks to this improvement, including things like complex hydraulic systems for machinery and intricate metal structures seen in modern buildings across the country.

Aluminum and High-Strength Alloys: Lightweight Yet Challenging Materials

The lightweight nature of aluminum has made it a go to material for aerospace and car manufacturers dealing with weight restrictions. But working with aluminum presents challenges because of how reflective it is and how quickly it conducts heat, which means standard laser settings won't cut it. For 6000 series alloys, pulsed fiber lasers are pretty much essential to manage the molten metal pools during cutting. When handling tougher stuff like 7075-T6 aluminum, operators need to crank up the power density by around 20% just to get those clean edges without burning through. Getting these parameters right matters a lot when manufacturing components where precision counts, think fuel system tubing or aircraft heat exchange systems where even minor imperfections can cause major problems down the line.

Processing Reflective Metals: Copper, Brass, and Inconel in Specialized Applications

Working with copper and brass can be quite tricky because these materials have really high infrared reflectivity plus excellent thermal conductivity. Modern cutting equipment gets around these issues by incorporating special anti-reflective lenses along with nitrogen assist gas, which makes it possible to achieve nice clean edges when working on things like electrical conduits or plumbing parts. When dealing with Inconel, that tough nickel based alloy found in some pretty harsh conditions, operators need laser systems rated at least 4 kW power. Getting good results means paying attention to details like focal length adjustments and maintaining proper gas flow rates throughout the process. This careful approach helps avoid those pesky micro cracks that could spell disaster for critical components in aircraft exhaust systems.

Aerospace and Defense Use Cases: Cutting Titanium and Exotic Alloys

Grade 5 titanium along with various nickel alloys play essential roles in manufacturing parts for jet engines, missiles, and satellites where strength matters most. When working with these materials, manufacturers typically cut them in environments without oxygen to avoid what's called alpha case formation. This surface layer can really weaken the metal over time, especially problematic for those thin walled titanium tubes used in many aerospace applications. The latest cutting technologies now achieve incredibly narrow kerf widths around 0.8mm when processing Inconel 718. Such precision meets the tough requirements set by defense contractors and space agencies for components in radar systems and engine parts alike.

How Material Properties Impact Cutting Precision and Quality

Material Thickness, Reflectivity, and Thermal Conductivity Considerations

The thickness of pipe walls has a real impact on how lasers penetrate material, which means operators often need to tweak power levels somewhere around plus or minus 15% just to keep the cutting process going at a steady pace while maintaining good quality cuts. Copper and brass present another challenge since they tend to bounce back some of the laser energy, making them about 20 to maybe even 35 percent less efficient to cut than regular steel does. When it comes to aluminum, its ability to conduct heat so quickly requires much faster movement across the surface. Most shops find they need to go roughly one and a half to twice as fast as what works for steel, otherwise too much heat gets lost and those nice clean edges start getting compromised. A recent paper from Materials Science and Engineering in 2023 looked into this stuff and found something interesting too. They measured surface roughness values (called Ra measurements) and saw differences of almost 40% when comparing shiny metals versus their dull counterparts, all other conditions being equal.

Achieving Tight Tolerances Across Different Metals

Keeping within tight tolerances around plus or minus 0.1 millimeters means adjusting laser settings on the fly depending on what kind of material we're working with. Carbon steel can handle pretty fast cutting rates between six and eight meters per minute while still holding onto good accuracy levels. When dealing with titanium alloys though, things get trickier. These materials need about thirty to forty percent slower movement speeds just to keep those heat affected areas under control. For hardened steels that are over 45 Rockwell C hardness, many shops find it helpful to run some sort of preheat cycle first. This helps prevent tiny cracks from forming when making those super precise cuts, which is something nobody wants to deal with later down the line.

Surface Quality and Edge Consistency in Final Parts

The edge perpendicularity of stainless steel really depends on how thick it gets, especially when the material goes beyond 0.2 mm in thickness. When using fiber lasers, we typically see angular precision below 0.5 degrees for thin wall aluminum parts between 1 and 3 mm thick. However things change with brass that's a bit thicker since thermal expansion tends to throw off the angles quite a bit, sometimes pushing them anywhere from 1.2 to 2.0 degrees off target. With nickel alloys though, keeping those cuts free from dross becomes a whole different ball game. The gas pressure needs to be controlled very carefully, staying within about plus or minus 0.15 bar range. This attention to detail makes all the difference for maintaining good surface finish quality in those critical high performance applications where nothing less than perfection will do.

Laser Type and Parameters: Matching Technology to Pipe Material

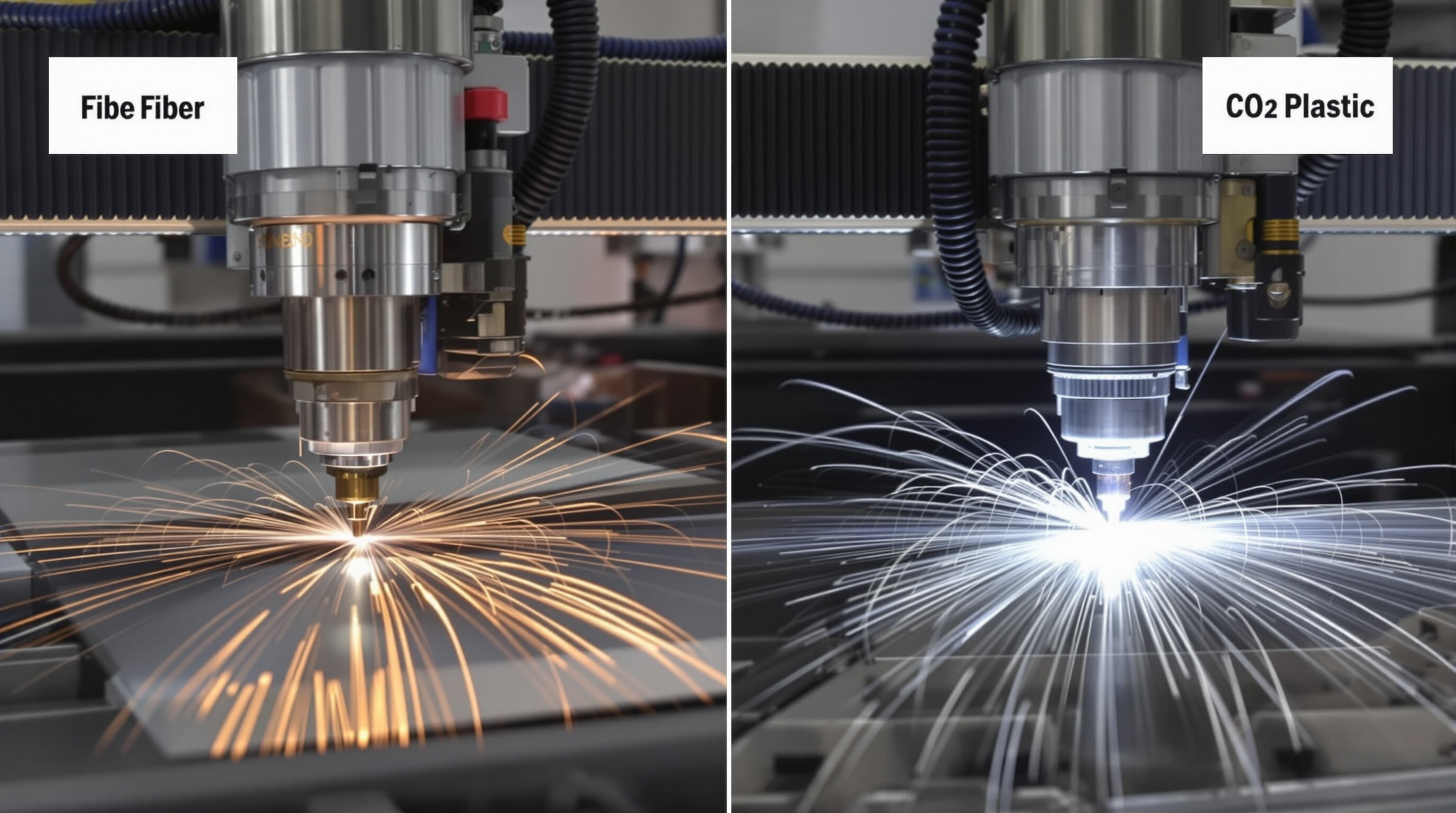

Fiber Laser vs. CO2 Laser: Performance Across Metal Types

When it comes to cutting metal pipes, fiber lasers have become the go-to option because they work really well with conductive materials. These lasers can create very narrow cuts, sometimes less than 20 micrometers wide in stainless steel, and cut through 2mm thick material at speeds between about 15 to 25 meters per minute according to industry reports from last year. On the other hand, CO2 lasers do fine with things like PVC pipes but run into problems when dealing with shiny metals such as aluminum and copper. The beams tend to bounce off these surfaces instead of being absorbed properly, which makes them much less efficient for these types of jobs.

| Laser Type | Best For | Cutting Speed* | Reflectivity Tolerance |

|---|---|---|---|

| Fiber | Steel, titanium, nickel alloys | 15–25 m/min | High |

| CO2 | Plastics, composites, thin copper | 8–12 m/min | Limited |

*Based on 2 mm thickness

Optimizing Power, Speed, and Focus for Reflective or Dense Materials

When working with reflective metals, manufacturers typically turn to pulsed fiber lasers that operate with dwell times below 500 nanoseconds. This helps minimize unwanted reflections from the metal surface and keeps the cutting process stable. For tougher materials like dense alloys such as Inconel 718, achieving full penetration requires laser systems capable of delivering between 4 to 6 kilowatts of peak power. Many shops have found that adaptive focus control works wonders in precision cutting tasks, especially in industries like aerospace manufacturing. One company reported cutting their titanium tube scrap rate down by nearly 37% after implementing this technology. They managed to maintain an impressive tolerance level of plus or minus 0.1 millimeters even when dealing with hundreds of different part shapes and complex geometries.

Case Study: High-Precision Cutting of Aerospace-Grade Titanium Tubes

Research from 2024 showed that when using 1 micrometer fiber lasers, they managed to get nearly perfect cuts in Ti-6Al-4V tubing for satellite fuel systems, hitting around 99.2% accuracy. The real breakthrough came when engineers adjusted the pulse frequency to about 2.5 kilohertz and set the nitrogen assist pressure at 12 bar. With these settings, they completely got rid of those pesky micro fractures and were able to cut through tubes with just 0.8 mm walls at an impressive speed of 18 meters per minute. That's actually 63 percent faster than what traditional methods could manage, all while keeping the edges looking good and intact.

Best Practices for Selecting Materials in Pipe Laser Cutting Applications

Balancing Cost, Durability, and Processability in Material Choice

When picking materials for manufacturing, companies need to balance what the part actually needs to do against how much money they want to spend making it. Carbon steel like ASTM A36 remains popular because it can handle serious stress (over 450 MPa tensile strength) and works reliably with lasers, all while keeping costs down on a per foot basis. Switching to aluminum cuts weight significantly around 60% lighter but comes with headaches for laser operators who need nitrogen assistance and must constantly tweak settings since metal reflects laser beams so strongly. Aerospace grade titanium definitely costs more about $12 to $18 extra per linear foot but manufacturers still go this route when working on projects for defense systems, medical implants, or spacecraft components. These specialized applications demand materials that won't corrode easily, maintain their strength despite being lightweight, and won't cause problems inside human bodies if used medically.

Matching Pipe Material Properties with Laser System Capabilities

The thickness of materials along with how they react to heat determines what kind of precision we can actually achieve in practice. Take stainless steel for instance, a 3 kW fiber laser will handle 6 mm material pretty well, giving us around ±0.1 mm accuracy. But when dealing with copper at the same thickness, things get trickier. We need at least a 6 kW system here, plus proper back reflection protection just to maintain decent edge quality. Recent improvements in pulsed fiber tech have made real progress though. Now we can cut through 8 mm aluminum pipes at speeds up to 12 meters per minute with only 20 psi nitrogen assistance, and still get those clean cuts without any dross issues. When working with tough alloys such as Inconel 625, operators typically slow down their feed rate about 40% below what would work for regular carbon steel. This adjustment helps prevent those annoying micro cracks while keeping the surface finish right around Ra 3.2 microns, which is pretty good considering the challenges these materials present.

FAQs

What materials are most commonly used with pipe laser cutting machines?

Carbon steel and stainless steel are commonly used due to their strength and predictable laser cutting behavior. Aluminum, copper, brass, Inconel, and high-strength alloys are also frequently cut using laser technology.

Why are fiber lasers preferred over CO2 lasers for cutting metals?

Fiber lasers are preferred due to their ability to cut conductive materials with high precision, whereas CO2 lasers can struggle with shiny metals.

What challenges are associated with cutting aluminum with lasers?

Aluminum is highly reflective and conducts heat quickly, requiring specific laser settings and additional assistance for effective cutting.

Table of Contents

-

Common Pipe Materials Compatible with Pipe Laser Cutting Machines

- Carbon Steel and Stainless Steel: Industrial Standards for Precision Cutting

- Aluminum and High-Strength Alloys: Lightweight Yet Challenging Materials

- Processing Reflective Metals: Copper, Brass, and Inconel in Specialized Applications

- Aerospace and Defense Use Cases: Cutting Titanium and Exotic Alloys

- How Material Properties Impact Cutting Precision and Quality

- Laser Type and Parameters: Matching Technology to Pipe Material

- Best Practices for Selecting Materials in Pipe Laser Cutting Applications

- FAQs