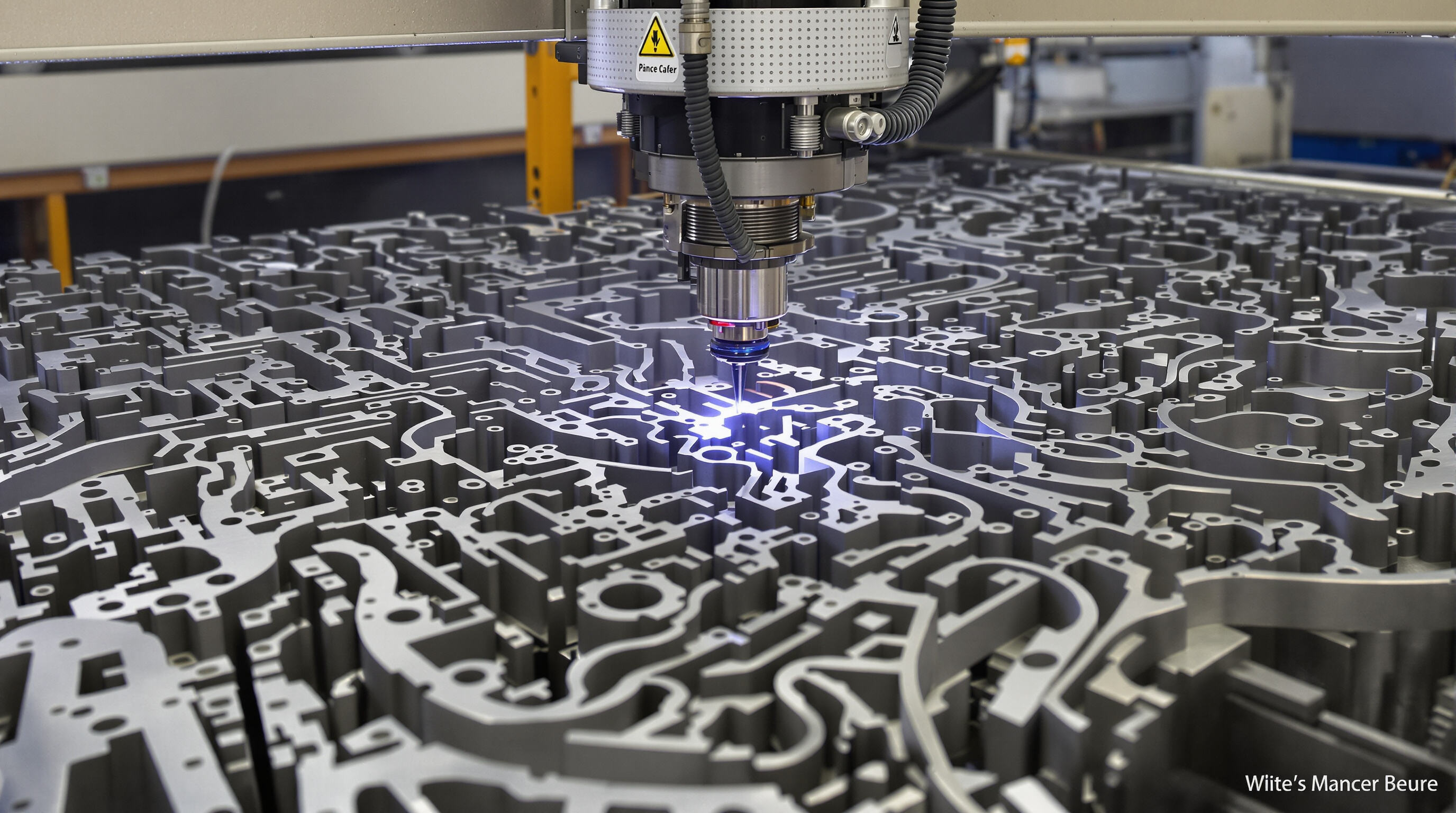

Unmatched Precision and Accuracy in Complex Metal Shaping

Tolerances in Metal Laser Cutting for High-Precision Components

Modern metal laser cutting machines achieve sub-50 micron tolerances (IntechOpen 2023), meeting the strictest requirements for aerospace actuators and medical device components. This precision stems from closed-loop positioning systems and thermal compensation modules that maintain accuracy across 24/7 production cycles.

Superior Edge Quality and Close Tolerance Capabilities

Fiber laser systems produce edge roughness values below Ra 1.6 µm without secondary finishing—critical for hermetic seals in chemical processing equipment. The concentrated 1070 nm wavelength enables kerf widths under 0.15 mm, allowing designers to nest complex geometries 37% tighter than plasma-cut alternatives.

How Non-Contact Processing Reduces Material Deformation

Unlike mechanical punching that imparts 12–18 kN/cm² of force, laser cutting applies zero tool pressure. This eliminates warping in <3mm stainless steel sheets, burr formation on copper EMI shielding components, and microcracking in tempered aluminum aerospace brackets.

Comparison of Laser Cutting vs. Mechanical Methods in Precision

| Parameter | Fiber Laser Cutting | Mechanical Punching |

|---|---|---|

| Positional Accuracy | ±0.02 mm | ±0.1 mm |

| Edge Angle Deviation | 0.5° | 2–3° |

| Repeatability (10k cuts) | 99.98% | 98.4% |

| Tool Wear Impact | None | +0.05 mm/die |

The non-contact process maintains consistent accuracy through 100,000+ operating hours, unlike mechanical systems requiring weekly die adjustments.

Enabling Complex Geometries and Design Flexibility with Metal Laser Cutting Machines

Complex Shapes and Intricate Designs Made Possible by Laser Technology

Laser cutting machines have changed how manufacturers approach metal work because they can create shapes that regular tools just cant do. Traditional cutting methods are limited by the size of actual cutting bits, but fiber lasers handle metals ranging from 0.1 to 40 mm thick with incredibly thin cuts sometimes as narrow as 0.1 mm wide. The level of detail possible opens up all sorts of applications. For instance, tiny holes under half a millimeter work great for electronic device shielding. Car parts need those smooth curves with almost no deviation plus there are these fancy brackets used in airplanes that get cut from one big sheet instead of separate pieces. When it comes to computer aided design and manufacturing software, engineers find it much easier now to take their complicated 3D designs and turn them into instructions the machines actually understand. This means what gets made on the factory floor looks exactly like what was drawn on paper back at the design stage.

Design Considerations for Optimizing Complex Geometries in Laser Cutting

To maximize laser cutting efficiency for intricate parts:

| Factor | Impact on Design | Optimization Strategy |

|---|---|---|

| Kerf width (0.1–0.3 mm) | Affects interlocking part clearances | Compensate in CAD models |

| Heat-affected zone | Risks warping in thin (<1 mm) metals | Adjust power/speed ratios |

| Internal corner radii | Minimum 0.2× material thickness | Use adaptive cornering algorithms |

Minimal Material Waste Through Tight Nesting and High Yield Efficiency

Advanced nesting software boosts material utilization to 92–98% by optimizing part arrangement. For example, cutting 100 stainless steel HVAC components from a 1500×3000 mm sheet reduces scrap by 35% compared to plasma cutting. Continuous cutting modes and automatic sheet remnant tracking further enhance yield in high-volume production runs.

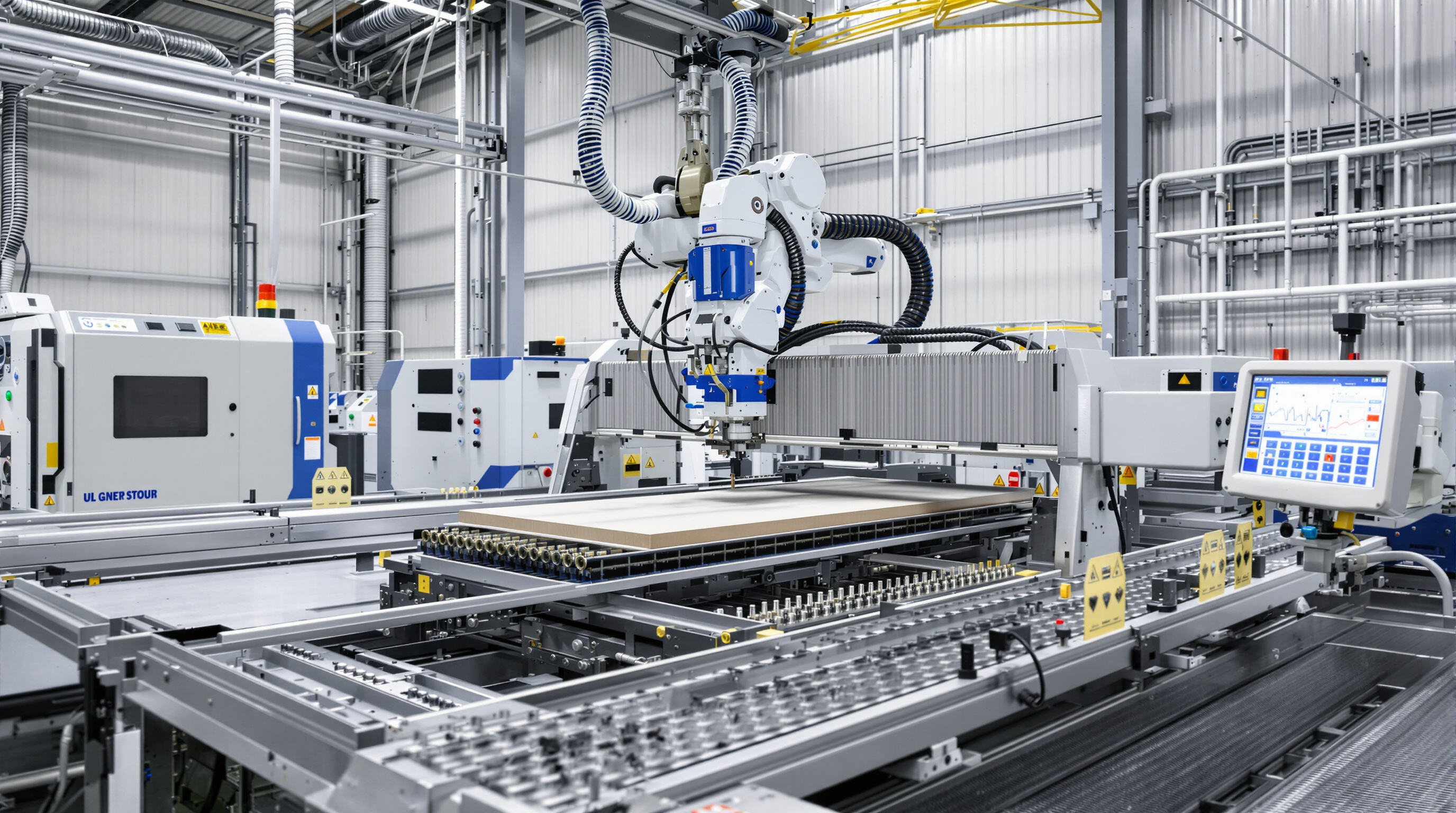

CNC Automation and Smart Features in Modern Metal Laser Cutting Machines

Integration of CNC Control in Metal Laser Cutting Machine Workflows

Today's metal laser cutting equipment can hit around 0.1 mm repeatability thanks to those fancy CNC systems we all know as Computer Numerical Control. What makes these machines so good at their job? They control three main things at once: how much power the laser puts out, where it moves across the material, and the flow rate of the assist gas. There are hundreds of different settings programmers can tweak, which means factories can run nonstop even when making really complicated shapes. When manufacturers start integrating Industry 4.0 technologies into their operations, they get another boost. The machines actually adjust themselves while working based on what the sensors tell them about the material being cut. Setup doesn't take nearly as long anymore either. Some shops report cutting down their preparation time by almost a third compared to old fashioned manual setups from just a few years back.

Automation and Productivity Gains Through Robotics and Continuous Operation

Robotic loading systems paired with multi-table workflows boost productivity by 40% in automotive sheet metal applications. A single operator can manage six machines simultaneously through centralized HMI interfaces, achieving 93% material utilization via AI-optimized nesting.

Smart Features Enhancing Precision and Process Monitoring

Beam quality sensors maintain <0.9 mm·mrad stability during 10-hour runs, while thermal compensation algorithms counteract lens heating effects (±0.05 mm drift). Predictive maintenance systems forecast nozzle wear 48 hours before failure, minimizing unplanned downtime.

Balancing High Initial Cost With Long-Term ROI From Automation

While advanced metal laser cutting machines require 20–30% higher upfront investment than mechanical alternatives, their energy-efficient fiber lasers (3.5 kW average consumption vs. 7 kW for CO₂ models) and reduced labor costs deliver ROI within 18–26 months for mid-volume manufacturers.

Optimizing Key Parameters for High-Quality Laser Cutting Results

Metal laser cutting machines achieve peak performance when operators balance three interdependent variables: laser power, cutting speed, and assist gas selection.

Laser Power, Cutting Speed, and Assist Gas Selection

Most modern cutting systems work within a range of about 1 to 20 kilowatts. When dealing with thicker materials, having more power means faster cuts, though it comes at the cost of needing really good heat control. The ideal cutting speed usually falls somewhere between 5 and 50 meters per minute. This helps keep things efficient without warping the material too much from all that heat. For different metals, operators rely on specific assist gases. Oxygen works well for carbon steel cuts, while nitrogen is better suited for stainless steel applications. These gases help prevent unwanted oxidation during the process. But watch out if the gas pressure isn't right. Even small mistakes here can lead to significant problems, especially with thinner materials where edge accuracy might drop around 30% when settings are off just slightly.

Impact of Beam Quality and Focal Spot Size on Cut Accuracy

Beam quality (M² ≤ 1.1 in advanced fiber lasers) determines energy distribution, with tighter focal spots (0.1–0.3 mm) enabling intricate features. A 2024 Precision Manufacturing Report found that lasers maintaining ±0.05 mm focal depth consistency produce 98% first-pass yield in aerospace components.

Material Thickness and Type: Tailoring Parameters for Complex Shaping

When working with stainless steel thicker than 15 mm, laser systems need about 40 percent more power compared to similar thicknesses of aluminum. Copper alloys present another challenge altogether because they tend to reflect the laser beam, so most operators switch to pulsed cutting modes instead of continuous ones. For titanium sheets below 6 mm thick, running at around 25 meters per minute works best when combined with argon gas shielding during the cut. Many shops have found that investing in adaptive parameter databases pays off handsomely. These systems cut down on wasted material from test cuts by roughly two thirds, which is huge savings. At the same time, they maintain pretty tight tolerances too, keeping positional errors within plus or minus 0.1 mm even when switching between different materials in the same production run.

Critical Applications in Automotive and Aerospace Industries

Role of Metal Laser Cutting Machines in Complex Metal Shaping for Aerospace and Automotive Sectors

Laser cutting machines for metals can hit tolerances around ±0.05 mm, which is pretty much essential when making parts like aerospace fuel nozzles or transmission components for cars. Compared to plasma cutting methods, these laser systems typically offer about 15 to 25 percent better dimensional accuracy, something manufacturers need to meet those strict AS9100 standards in the aerospace industry. On the automotive side, cutting ultra high strength steel (UHSS) with lasers helps cut down vehicle weight by roughly 19 percent without sacrificing crash safety performance. This kind of precision makes all the difference in both industries where even small improvements matter a lot.

Case Study: Laser-Cut Structural Components in Aerospace Systems

A recent aerospace project used 6 kW fiber laser cutting machines to produce titanium wing ribs with 0.1 mm wall thicknesses. The non-thermal process eliminated warping in thin-section materials, achieving 99.8% dimensional accuracy across 12,000 components. This application reduced assembly time by 40% compared to conventional machined parts.

Supporting Automotive Lightweighting Through Precision Sheet Metal Fabrication

Laser cutting facilitates complex 3D shapes in aluminum and advanced composites, critical for EV battery enclosures and chassis components. Automotive manufacturers report 22% material savings through AI-optimized nesting patterns, while maintaining <0.2 mm positional accuracy across high-volume production runs.

Trend: Rising Adoption of Ultra-High Power Fiber Laser Cutting Machines

The automotive sector now deploys 30 kW fiber lasers to cut 25 mm thick boron steel at 1.8 m/min speeds—a 300% productivity gain over previous systems. Aerospace suppliers are adopting dual-laser configurations to maintain ±0.02 mm accuracy when processing heat-sensitive nickel alloys for turbine components.

Key advantages driving adoption:

- Precision scaling: 8% annual improvement in cutting accuracy (2019–2024)

- Material flexibility: Single-machine capability for 30+ metal grades

- Energy efficiency: 40% reduction in power consumption vs. CO₂ lasers

This technology convergence positions laser cutting as the foundational process for next-gen transportation manufacturing, with 73% of Tier 1 suppliers now standardizing on laser-based metal shaping workflows.

FAQ

What are the tolerances achievable with modern metal laser cutting?

Modern metal laser cutting machines can achieve sub-50 micron tolerances, allowing for high precision needed in industries like aerospace and medical devices.

How does laser cutting compare to mechanical punching in terms of precision?

Laser cutting generally offers better positional accuracy (±0.02 mm compared to ±0.1 mm for mechanical punching) and repeatability, without the tool wear impact seen in mechanical methods.

What makes laser cutting advantageous for complex geometries?

Laser cutting allows for incredibly thin cuts and intricate designs, which are difficult to achieve with traditional mechanical methods. This is facilitated by fiber lasers that can handle a broad range of material thicknesses.

What role does automation play in modern laser cutting systems?

CNC controls and robotic loading systems improve the productivity and precision of laser cutting machines, enabling better material utilization and reducing setup times.

How is laser cutting beneficial for the automotive and aerospace sectors?

The precision and flexibility of laser cutting machines are critical for manufacturing complex parts in aerospace and automotive industries, offering better dimensional accuracy and material savings.

Table of Contents

- Unmatched Precision and Accuracy in Complex Metal Shaping

- Enabling Complex Geometries and Design Flexibility with Metal Laser Cutting Machines

- CNC Automation and Smart Features in Modern Metal Laser Cutting Machines

- Optimizing Key Parameters for High-Quality Laser Cutting Results

-

Critical Applications in Automotive and Aerospace Industries

- Role of Metal Laser Cutting Machines in Complex Metal Shaping for Aerospace and Automotive Sectors

- Case Study: Laser-Cut Structural Components in Aerospace Systems

- Supporting Automotive Lightweighting Through Precision Sheet Metal Fabrication

- Trend: Rising Adoption of Ultra-High Power Fiber Laser Cutting Machines

-

FAQ

- What are the tolerances achievable with modern metal laser cutting?

- How does laser cutting compare to mechanical punching in terms of precision?

- What makes laser cutting advantageous for complex geometries?

- What role does automation play in modern laser cutting systems?

- How is laser cutting beneficial for the automotive and aerospace sectors?