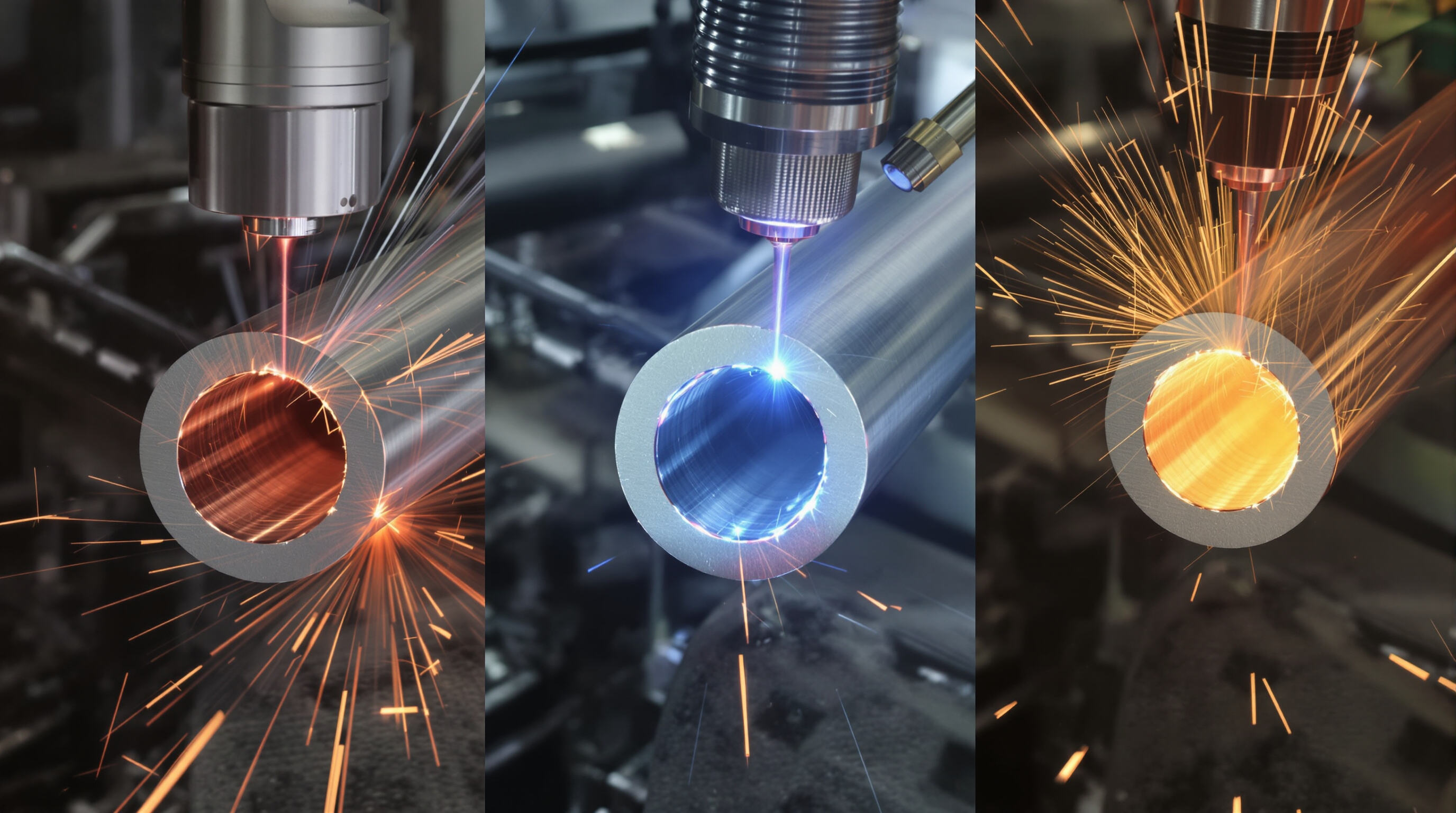

The effectiveness of laser cutting really hinges on how different materials take in and spread out energy. Take metals for instance stainless steel and aluminum behave quite differently because their thermal properties just aren't the same. Stainless steel doesn't conduct heat very well about 15 W/mK which means the heat tends to build up in one spot. Aluminum tells a different story though with its much higher conductivity around 205 W/mK so the heat spreads out quickly making it harder to get consistent melts. Copper is another beast altogether. At 1 micron wavelength, copper reflects back almost all the light 95% to be exact. This reflection problem demands some serious adjustments to the laser beam if we want stable cuts. Looking at modern fiber lasers, they can grab nearly all the energy from steel close to 99% absorption but struggle quite a bit with copper where absorption drops to just 60-70%. That's why shops working with copper often need special techniques and equipment to make things work right.

When it comes to cutting stainless and mild steel, fiber lasers simply beat CO2 systems hands down, especially when working with thin walled pipes where they can cut up to 30% faster. The reason? Fiber lasers operate at a much shorter wavelength around 1.08 microns which gets absorbed better by metals like steel, so there's less wasted energy and shorter cycle times overall. On the flip side, CO2 lasers have those longer wavelengths at 10.6 microns that actually work better for certain jobs. They don't reflect as much when cutting non ferrous metals like brass, so manufacturers still rely on them for specific tasks where stability matters most. Looking at recent numbers from the aerospace sector in 2023, companies using fiber lasers saw their stainless steel cutting costs drop by about $18.50 per meter versus traditional CO2 setups. Most of this savings came from needing less assist gas during operation plus better electrical efficiency across the board.

Three variables critically influence cut quality:

For carbon steel, maintaining gas pressure between 1.2–1.5 bar is essential to avoid slag formation and ensure consistent cut quality.

Stainless steel and mild steel represent over 65% of industrial tube laser cutting applications (IMTS 2023), valued for their balance of strength, weldability, and responsiveness to laser energy. These materials can be processed from 0.5 mm to 25 mm thickness with minimal heat-affected zones, making them ideal for high-precision manufacturing.

Stainless steels like 304 and 316 from the austenitic family see lots of action because they contain around 18 to 20 percent chromium. That's what gives them such good protection against rust and chemical damage. When it comes to cutting these materials, today's fiber laser technology makes it possible to get really tight cuts. We're talking about kerf widths down to just 0.1 millimeters, with dimensional accuracy within plus or minus 0.05 mm even on pipes that are 15 mm thick. The medical equipment manufacturers and those making tubes for food processing absolutely need this kind of precision. Their products require surfaces that are completely smooth without any rough edges or burrs, something that only advanced laser systems can consistently deliver across production runs.

To achieve oxidation-free cuts, nitrogen assist gas at 12–16 bar is recommended for 3–8 mm stainless steel tubes. For thicker sections (10–15 mm), a 4 kW fiber laser operating at 0.8–1.2 m/min ensures dross-free results while minimizing thermal distortion. These parameters support high repeatability in automated production environments.

The relatively low carbon content in mild steel (less than 0.3%) means it vaporizes quickly when heated to approximately 1,500 degrees Celsius. This property makes mild steel particularly well suited for fiber laser cutting applications. With a standard 6 kW laser system, operators can slice through 20 mm thick mild steel pipes at impressive speeds reaching around 2.5 meters per minute. The cuts produce almost vertical edges with minimal angular deviation (about plus or minus half a degree), which is great news for welders who don't need to spend extra time on post-cut finishing work. Looking at the bottom line, these laser systems offer significant savings too. Industry data from FMA 2023 shows operating costs drop by roughly 23% when switching from traditional plasma cutting methods.

For carbon steel pipes exceeding 25 mm in thickness, pulsed laser modes (1–2 kHz) help control heat input and prevent warping. Using oxygen-based assist gas blends improves slag ejection, reducing residue by 40% in 30 mm sections. This ensures dimensional accuracy for structural components in construction and heavy machinery.

A Tier 1 automotive supplier implemented 3D pipe laser cutting to produce 5,000 fuel-injection tubes daily with 99.7% dimensional accuracy. The same system achieved 0.12 mm repeatability on SS304 aircraft hydraulic brackets, cutting post-processing time by 62% compared to conventional machining methods.

Aluminum reflects light really well actually around 90% at those typical laser wavelengths we work with and it loses heat pretty fast too. These characteristics make it tough to get the laser to absorb energy consistently during processing. What happens next? Well, the melt pool gets all over the place and the kerf ends up looking uneven, particularly when dealing with those thin walled tubes that are so common in manufacturing. Thermal conductivity is another challenge here since aluminum conducts heat about five times better than stainless steel does. Because of this, operators need to tweak their parameters very carefully if they want clean cuts without that annoying dross buildup that nobody wants to deal with after the fact.

Using nitrogen as an assist gas reduces oxidation by up to 70% compared to oxygen. Combining this with high-frequency pulsed laser modes (≥2,000 Hz) and optimized nozzle standoff distances (0.8–1.2 mm) improves edge smoothness by 25%. These adjustments are crucial for achieving clean, weld-ready surfaces in high-value applications.

A manufacturer ran some tests back in 2023 where they managed to get around plus or minus 0.05 millimeter precision when making electric vehicle battery trays with their 6 kilowatt fiber laser setup. They also noticed something interesting when cutting those 6xxx series aluminum tubes - by keeping track of temperature changes as they went along, they cut down waste material dramatically, going from roughly 12 percent scrap down to just over 3 percent. According to recent studies published somewhere like the Journal of Materials Processing Technology, there's definitely been a shift towards using more aluminum for making cars lighter weight. Electric car makers are now swapping out about forty percent of what used to be steel parts for these specially cut aluminum pieces instead.

Fiber lasers now dominate aluminum tube cutting, accounting for 68% of installations globally. Their 1.08 μm wavelength offers better absorption than CO₂ lasers, enabling cutting speeds of 1.2–1.8 m/min on 8 mm aluminum with dross-free results. This performance drives adoption in HVAC, transportation, and renewable energy sectors.

When working with copper and brass materials, they tend to bounce back around 95% of laser energy at those infrared wavelengths according to some recent research from the Laser Processing Institute in 2023. This reflection creates real problems for optical parts and makes maintaining stable processing conditions quite challenging. Brass adds another layer of difficulty because when cut, the zinc component tends to evaporate, leading to inconsistent cuts with uneven edges and sometimes even tiny holes forming in the material. To get around these issues, most professionals rely on pulsed laser settings combined with nitrogen gas assistance. The pulses help control the melting better while nitrogen keeps oxidation at bay, making the whole cutting process much more predictable and reliable for manufacturers dealing with these tricky metals.

Fiber lasers today manage to slice through pure copper sheets as thick as 3 mm when operating at 1 kW power or above, delivering around 0.1 mm accuracy thanks to better beam control technology. But there's a catch worth mentioning here: these cuts take about 30 to 40 percent longer compared to working with steel materials because copper conducts heat so efficiently. What makes this possible is the laser's 1.08 micrometer wavelength which gets absorbed by copper at about 22%, making it almost three times better than traditional CO2 lasers. This improvement has opened doors for manufacturing delicate components like electrical conduits with thin walls and specialized heat exchange systems where precision matters most.

Three proven approaches enhance copper and brass processing:

These methods reduce dross formation by 62% and maintain cutting speeds up to 20 m/min on 2 mm brass tubes.

The demand for precision brass parts has gone up by almost half according to the latest 2023 Global Industrial Cutting Survey, but there are still some pretty big technical hurdles to overcome. Getting those really tight tolerances below 0.2 mm needed for things like decorative trim, marine hardware, and medical equipment just doesn't happen easily with regular cutting systems. Sure, 6 kW fiber lasers can handle 8 mm brass with about 0.25 degree accuracy, but running one of these machines costs around $180 per hour. That kind of price tag means most companies only bring them out when absolutely necessary, typically reserved for expensive aerospace applications or specialized instrumentation where such extreme precision actually matters.

Modern pipe laser cutting machines deliver varying performance across key materials:

| Material | Maximum Thickness (Fiber Laser) | Cut Quality | Key Considerations |

|---|---|---|---|

| Stainless Steel | 25 mm | Excellent | Requires nitrogen assist gas |

| Mild Steel | 30 mm | High Precision | Optimal with oxygen assist |

| Aluminum | 15 mm | Good | Anti-reflective coatings recommended |

| Copper | 6 mm | Moderate | High-powered lasers (>6 kW) preferred |

| Brass | 12 mm | Consistent | Pulse frequency adjustments critical |

Stainless and mild steels remain the most laser-friendly, consistently achieving tolerances under ±0.1 mm. Aluminum requires 30% faster cutting speeds than steel to prevent dross, while copper’s reflectivity limits success—only 42% of manufacturers report reliable results with pure copper, according to 2023 fabrication surveys.

The aerospace and medical sectors increasingly use fiber lasers to cut titanium pipes up to 10 mm thick. Effective processing requires:

Nickel-based superalloys like Inconel are seeing 19% annual growth in laser cutting adoption, particularly for high-temperature exhaust components requiring durability up to 1,200°C.

Four factors determine optimal laser settings:

Operators should perform test cuts when working with new alloys, as even a 0.5% variation in composition can alter cutting speeds by 12–15%.

Laser cutting depends on how materials absorb and spread energy. Metals like stainless steel and aluminum have distinct thermal properties affecting their reaction to laser cutting.

Fiber lasers provide superior speed and efficiency compared to CO2 lasers, especially for thin-walled pipes, due to their shorter wavelength and better energy absorption.

Fiber lasers can cut copper and brass with certain adjustments like pulsed laser settings, but they require more power and time compared to softer metals.

Assist gases like nitrogen and oxygen are used to improve cut quality, prevent oxidation, and enhance efficiency depending on the material.

Yes, fiber lasers are increasingly used for aluminum cutting owing to their efficiency, though adjustments are needed due to aluminum's reflectivity and thermal conductivity.

Hot News

Hot News