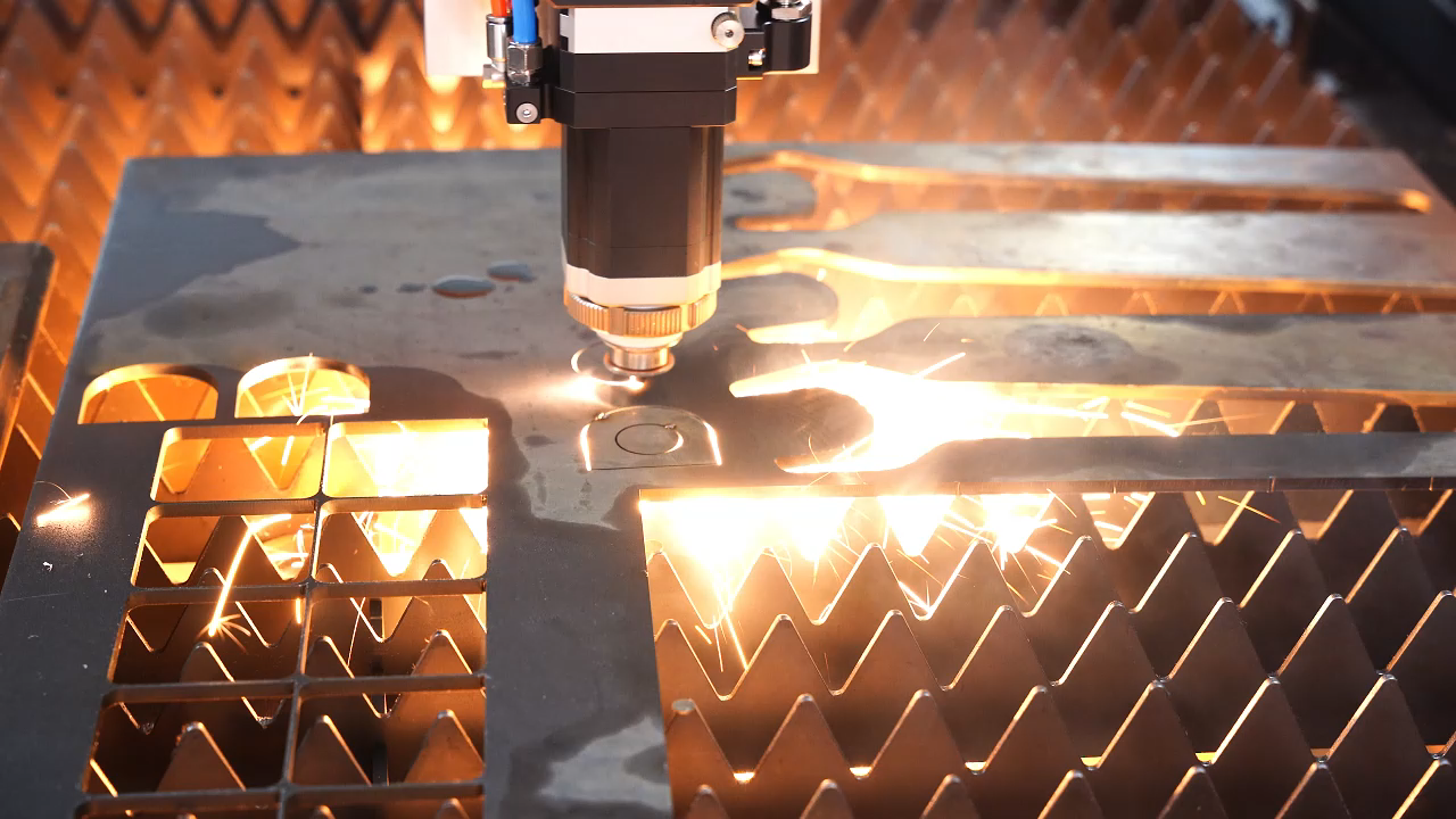

Fiber laser cutting technology represents a paradigm shift in industrial material processing, leveraging the unique properties of fiber-delivered laser beams to achieve unprecedented cutting precision and efficiency. The laser sources employ multiple diode pump modules coupled into double-clad gain fibers through proprietary beam combining techniques, generating output powers from 500W to 60kW with beam quality factors (M²) typically below 1.3. This exceptional beam quality enables focus spot diameters down to 10μm with depth of focus optimized for specific material thicknesses. The cutting mechanism involves sophisticated thermal processes where laser energy absorption varies with material properties and surface conditions, while assist gases play crucial roles in molten material ejection and oxidation control. Modern systems incorporate dynamic beam control with programmable focus positions and frequency modulation capabilities from 1-100kHz. Industrial implementations in construction steel fabrication demonstrate processing of 25mm structural steel with 12kW lasers at 1.2m/min, producing kerf widths of 0.3mm with excellent edge squareness. The technology proves indispensable in household appliance manufacturing, where 3kW systems cut 1mm galvanized steel at 35m/min with minimal zinc coating damage. For architectural applications, fiber lasers create intricate designs in 4mm copper sheets with cutting speeds of 8m/min and heat-affected zones under 50μm. Aerospace component manufacturers utilize the technology for processing 6mm Inconel alloys with nitrogen-assisted cutting producing oxidation-free edges ready for welding. Advanced systems feature integrated vision-based edge detection with accuracy of ±0.05mm and automatic piercing protocols that minimize nozzle damage. The operational architecture includes closed-loop cooling systems with precision temperature control and multi-stage filtration ensuring optical protection. Modern software platforms provide nesting optimization with material utilization rates exceeding 95% and cutting path simulation for thermal deformation prediction. The economic advantages manifest through reduced consumable costs with nozzle life extended to 400 cutting hours and 70% lower energy consumption compared to CO2 systems. For application-specific technical consultations and detailed process demonstrations, our technical team remains available to provide comprehensive support and equipment customization services.