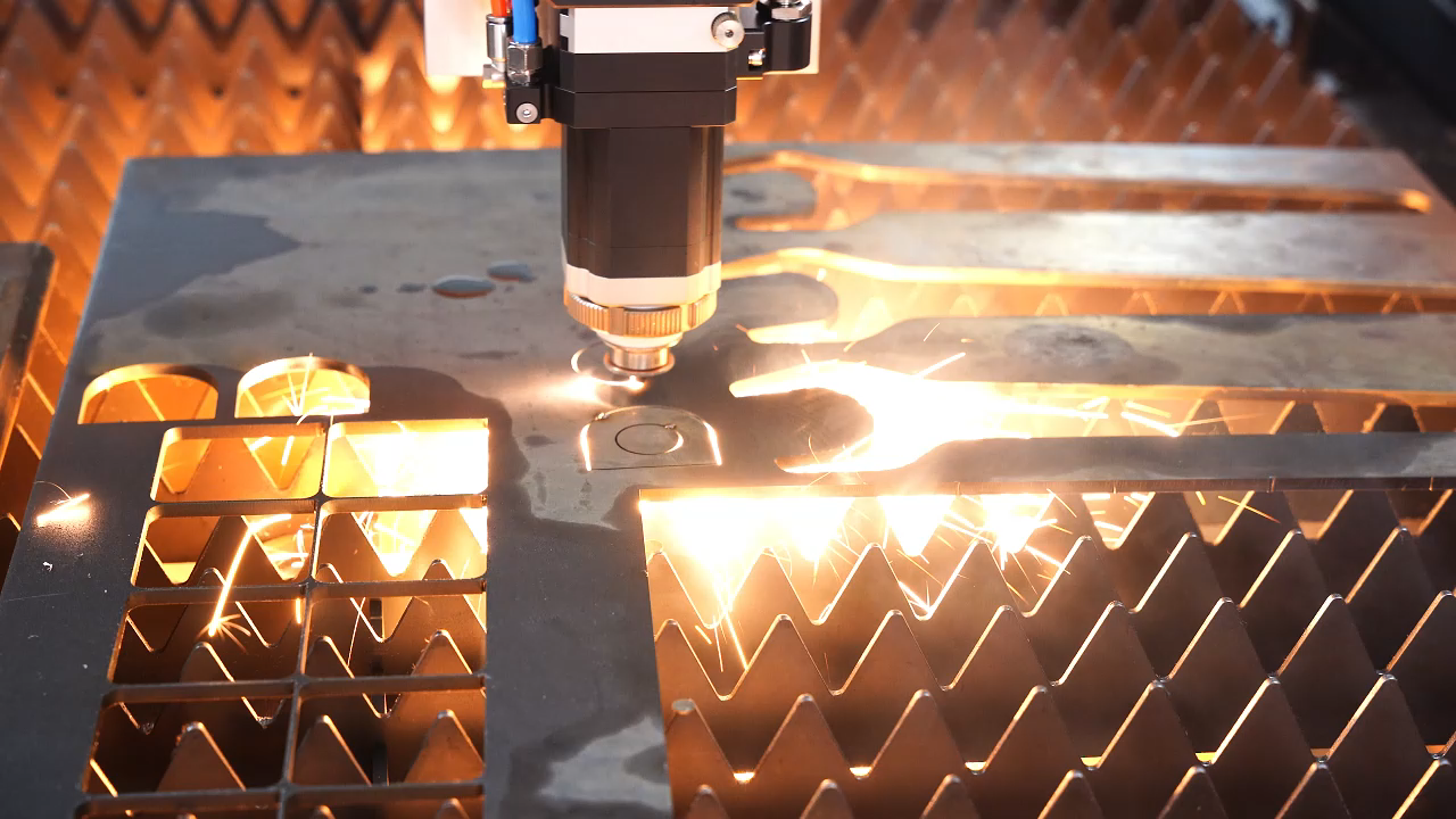

Contemporary fiber laser cutting technology harnesses the principle of stimulated emission within rare-earth-doped optical fibers to generate high-power laser beams with unprecedented beam quality. The laser resonators employ fiber Bragg gratings for wavelength stabilization, producing near-infrared radiation at 1070nm with spectral bandwidths under 5nm. This monochromatic light transmits through flexible delivery fibers with core diameters ranging from 50-200μm, maintaining beam parameter product values below 2.5 mm·mrad. The cutting mechanism involves precise thermal management where material removal occurs through melt-and-eject processes for metals, while sublimation cutting dominates for non-metallic materials. Advanced cutting heads feature automatic focus control with focal lengths variable between 125-300mm, coupled with pressure-regulated assist gas systems delivering up to 25bar for thick-section processing. Industrial implementations in railway manufacturing demonstrate capabilities in cutting 30mm stainless steel at 0.8m/min with kerf widths maintained at 0.3mm and perpendicularity within 0.2°. The technology shows remarkable versatility in food processing equipment fabrication, where 4kW systems process 6mm polished stainless steel at 5m/min while preserving corrosion resistance properties through oxidation-free cutting edges. For construction steelwork applications, fiber lasers handle 20mm structural steel with cutting speeds of 1.5m/min and edge quality requiring no secondary processing. Electronics industry applications include precision cutting of 0.3mm spring steel for connector components with dimensional accuracy of ±10μm. Modern systems incorporate intelligent nesting software that automatically optimizes cutting paths to minimize thermal distortion while achieving material utilization rates exceeding 90%. The operational infrastructure includes closed-loop cooling systems maintaining laser temperature within ±0.5°C and multi-stage filtration ensuring optical component protection. Advanced monitoring systems track cutting head collision avoidance through real-time force feedback and automatic retraction mechanisms. The technology's environmental profile includes 80% reduction in hazardous waste generation compared to plasma cutting and complete elimination of laser gas consumption. For specialized application requirements and complete technical documentation, please contact our engineering department for personalized equipment recommendations and process validation services.