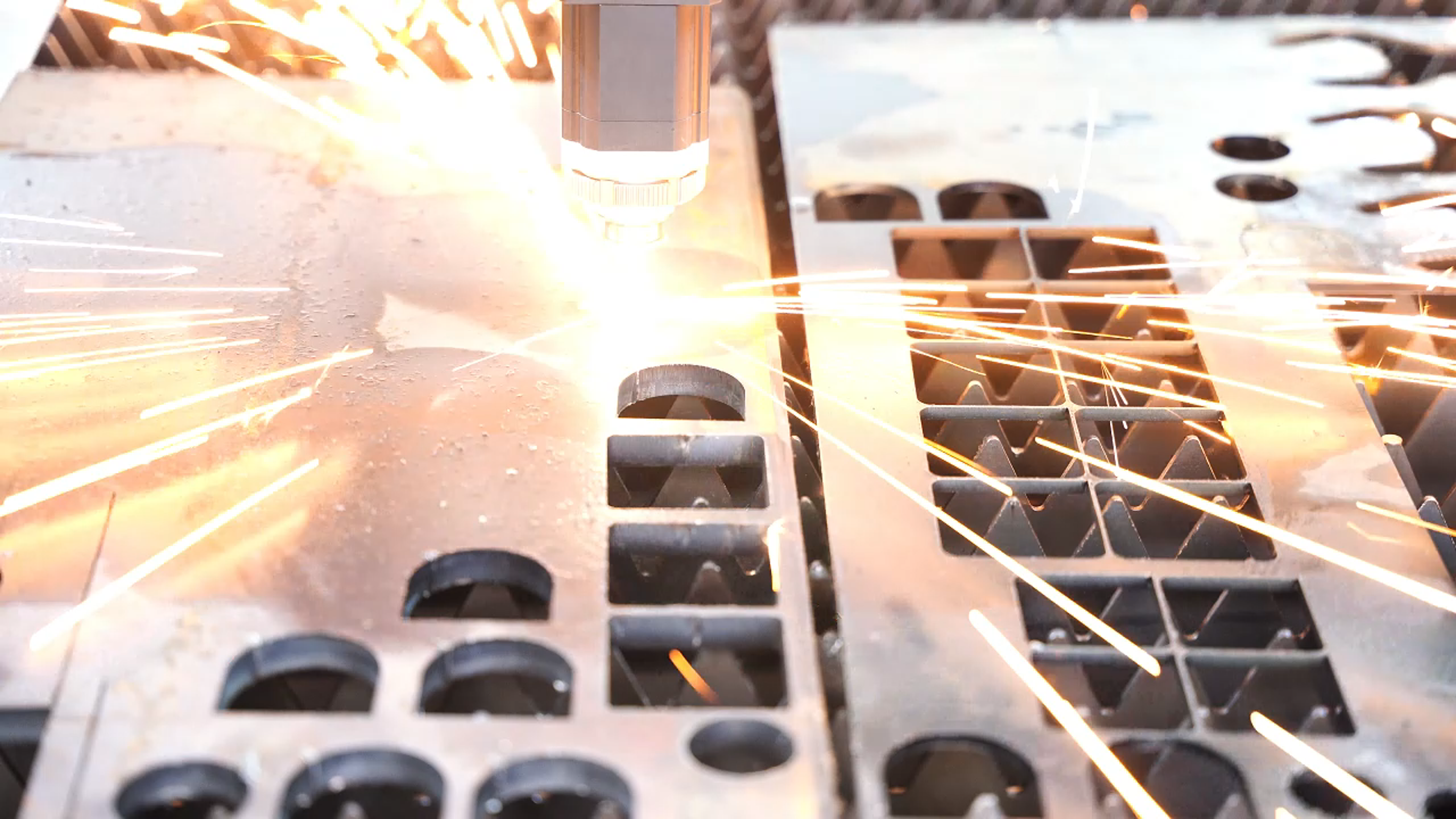

Fiber laser cutting technology embodies the convergence of photonic engineering and industrial automation, utilizing semiconductor-pumped fiber amplifiers to generate laser beams with unparalleled spectral purity. The laser resonators employ distributed feedback fiber Bragg gratings that stabilize output wavelengths at 1070±5nm with line widths under 0.5nm. This spectral characteristics enables superior absorption in metallic materials, particularly for copper and aluminum where absorption rates reach 30-40% compared to 5-8% for CO2 lasers. The cutting mechanism involves sophisticated heat management where laser energy interacts with materials through plasma-assisted cutting for thick sections and conduction-limited cutting for thin sheets. Modern systems incorporate beam delivery through fiber optic cables with core diameters of 50-100μm, maintaining beam quality during transmission over distances up to 50 meters. Industrial applications in mining equipment manufacturing demonstrate processing of 40mm wear-resistant steel with 20kW lasers at 0.6m/min, producing kerf widths of 0.5mm with minimal heat-affected zones. The technology proves transformative in consumer goods production, where 2kW systems cut 1mm coated steel at 40m/min with precision contours maintaining ±0.05mm tolerance. For architectural metalwork, fiber lasers process 6mm aluminum composite panels at 10m/min without delamination or thermal damage to coatings. Medical device manufacturers utilize the technology for cutting 0.8mm titanium implants with cutting edge angles controlled within 0.5° and surface roughness below Ra 1.6μm. Advanced systems feature automatic focal length adjustment through programmable Z-axis and real-time beam quality monitoring through integrated power sensors. The operational infrastructure includes smart chiller systems with flow rate control and leak detection, coupled with centralized exhaust management for fume extraction efficiency exceeding 99%. Modern software suites provide digital twin capabilities for process simulation and cutting parameter optimization through AI algorithms. The economic advantages include 50% reduction in maintenance costs compared to CO2 systems and 80% lower energy consumption per cutting meter. For project-specific technical requirements and equipment configuration details, our application engineering team provides comprehensive support and cost-benefit analysis.