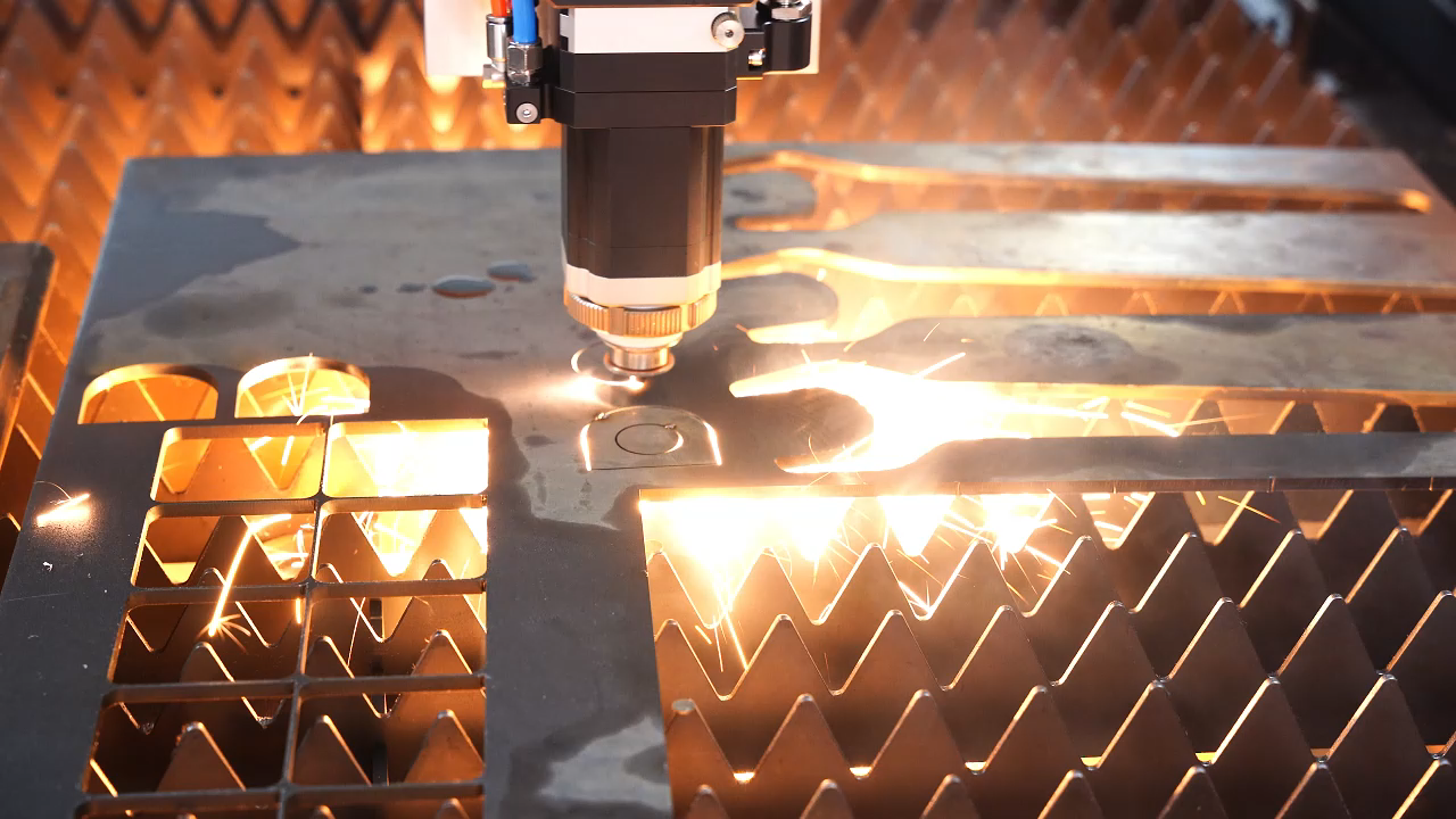

Fiber laser cutting systems represent a revolutionary advancement in thermal separation technology, characterized by their solid-state design that eliminates moving parts within the laser source. The core technology utilizes ytterbium-doped triple-clad optical fibers that generate laser beams with exceptional spectral purity and spatial coherence. These systems achieve wall-plug efficiencies of 35-40%, dramatically reducing operational costs while delivering maximum power stability with fluctuations below ±2% over extended operations. The cutting process employs sophisticated focal point control where beam focus positions are dynamically adjusted relative to material surface through non-contact height sensing systems. Modern cutting heads incorporate protective sapphire lenses with automated purge monitoring to maintain optical clarity, while nozzle designs optimized for specific material thicknesses ensure consistent gas flow dynamics. Industrial applications in heavy equipment manufacturing regularly process 25mm mild steel with 12kW systems, achieving cutting speeds of 1.2m/min with squareness tolerances within 0.5° and surface roughness below Ra 6.3μm. The technology demonstrates particular advantages in automotive component production, where 6kW lasers cut 4mm high-strength steel at 12m/min while preserving material metallurgical properties. For architectural metal fabrication, fiber lasers process perforated patterns in 3mm aluminum sheets with positioning accuracy of ±0.03mm across 6-meter sheets. Consumer electronics manufacturers utilize the technology for precise cutting of 0.5mm copper alloys with heat-affected zones controlled under 15μm. Advanced systems incorporate real-time beam quality monitoring through integrated power sensors and automatic calibration of collimation optics. The operational framework includes predictive maintenance systems that monitor diode pump life expectancy and fiber coupling efficiency, typically providing 100,000 hours of laser source operation. Modern installations feature complete digital integration with factory ERP systems, enabling real-time production tracking and remote parameter adjustment through secure cloud platforms. The economic advantages extend beyond energy savings to include reduced consumable costs with nozzle life extended by 300% compared to CO2 systems, and elimination of regular mirror alignment procedures. For detailed technical specifications and application-specific cost-benefit analysis, our technical support team remains available to provide comprehensive consultation services.