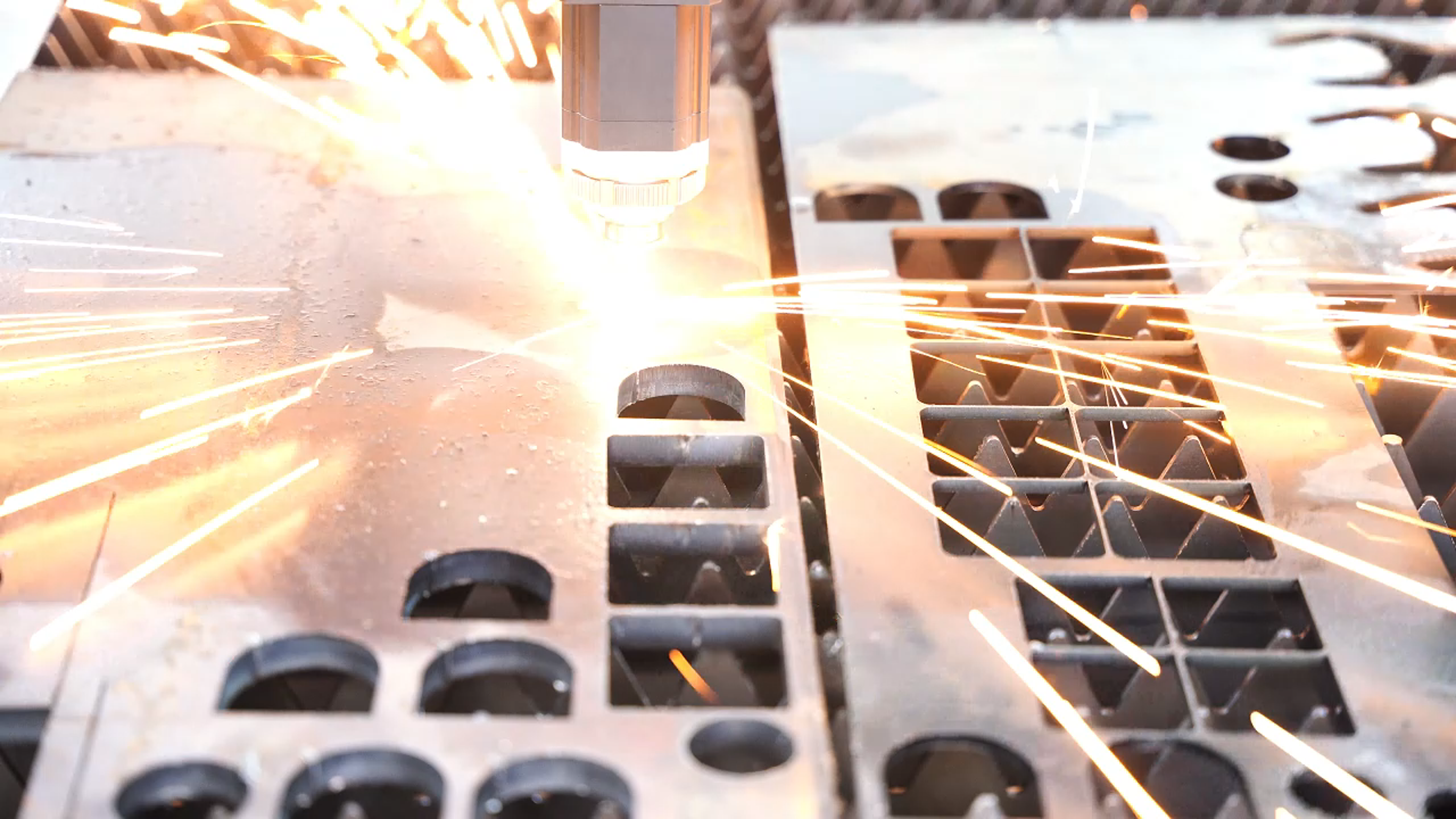

Fiber laser cutting technology represents a pinnacle of modern industrial manufacturing, utilizing solid-state laser generators that amplify light through doped optical fibers to produce an exceptionally concentrated energy beam. This coherent light source, typically operating at 1.064 μm wavelength, delivers superior photon quality with brightness levels exceeding 10^6 W/cm²·sr. The core technological advantage lies in the photoelectric conversion efficiency reaching 30-35%, significantly outperforming traditional CO2 lasers. These systems operate through a complex optical path where the initial laser diode pump source excites ytterbium-doped gain fibers, creating a high-power density beam that transmits through flexible process fibers to the cutting head. The cutting head incorporates proprietary collimating and focusing lenses, often with focal lengths adjustable between 7.5"-12", to concentrate the laser beam to a spot diameter ranging from 10-50 μm. This concentrated energy instantly vaporizes or melts materials while high-pressure auxiliary gases (oxygen for carbon steel, nitrogen for stainless steel) eject molten material from the kerf. Modern fiber laser cutters integrate sophisticated CNC systems capable of executing complex vector cutting paths with positioning accuracy of ±0.03mm and repeatability of ±0.02mm. The machines maintain optimal performance across diverse material thicknesses, typically processing mild steel up to 30mm, stainless steel to 25mm, and aluminum alloys to 20mm with cutting speeds reaching 40m/min for 1mm sheets. Industrial applications demonstrate remarkable efficiency in automotive chassis manufacturing, where 6kW systems process 5mm automotive grade steel at 8m/min with heat-affected zones below 50μm. Aerospace implementations regularly employ 12kW units for cutting titanium alloy components, achieving perpendicularity tolerances within 0.1° over 15mm thickness. The technology's flexibility shines in architectural metalwork projects, where nested cutting patterns optimize material utilization to 92% while maintaining cutting precision of ±0.05mm across 4x2 meter sheets. For electronic enclosure production, fiber lasers create vent patterns in 1.5mm aluminum with burr-free edges measuring under 10μm, eliminating secondary processing. Advanced systems incorporate real-time monitoring of nozzle distance through capacitive height sensors and automatic focal point adjustment via programmable Z-axis controls. Contemporary installations often integrate Industry 4.0 protocols with IoT connectivity for predictive maintenance alerts and cutting parameter optimization through cloud-based analytics platforms. The operational economics reveal significant advantages with electricity consumption reduced by 60-70% compared to conventional CO2 systems, and maintenance intervals extended to 20,000 operating hours for the laser source. For specific application requirements and detailed technical specifications, please contact our engineering team to receive customized solution proposals and operational cost analysis.