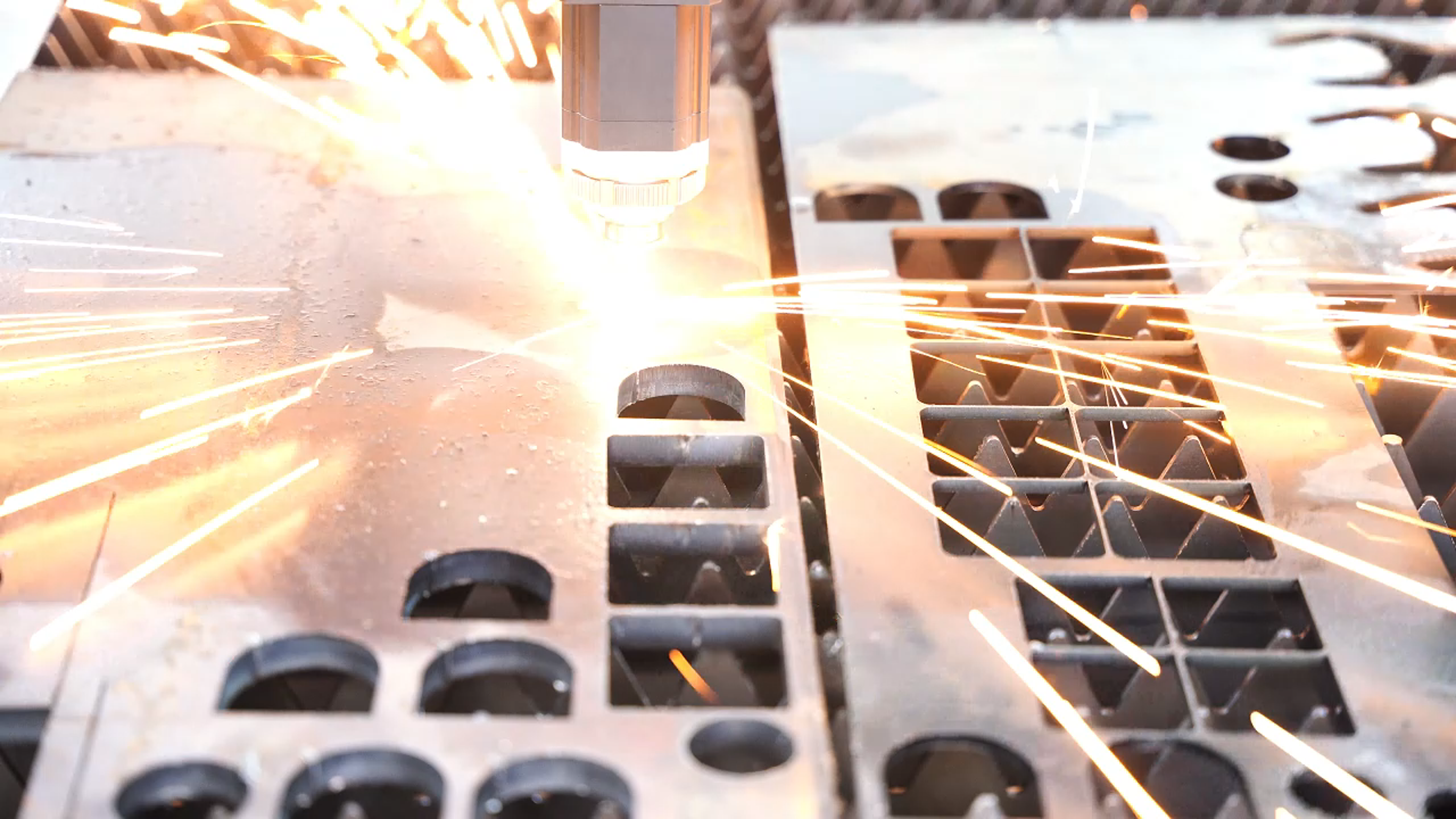

The technological foundation of fiber laser cutting rests upon the exceptional beam quality generated through all-fiber resonators employing ytterbium-doped double-clad fibers. These systems produce diffraction-limited laser beams with near-perfect Gaussian intensity distribution, enabling focus spot diameters below 20μm with Rayleigh lengths optimized for specific material thicknesses. The cutting process leverages precise energy coupling where material removal occurs through vaporization-dominated mechanisms for thin sheets and melt-and-eject processes for thicker sections. Modern industrial configurations incorporate collimating optics with focal lengths of 75-200mm and focusing lenses with 2.5-7.5 inch focal distances, providing working fields up to 6x3 meters. Advanced cutting heads feature automatic nozzle alignment with clearance detection through capacitive sensing, maintaining standoff distances of 0.5-1.5mm with ±0.1mm accuracy. Industrial implementations in automotive frame manufacturing process 8mm high-strength steel at 4m/min with 6kW systems, achieving tensile strength preservation in heat-affected zones. The technology demonstrates exceptional capability in electrical motor production, where 3kW lasers precision-cut 0.5mm silicon steel laminations at 80m/min with edge burrs controlled under 15μm. For commercial kitchen equipment fabrication, fiber lasers process 4mm stainless steel with cutting speeds of 8m/min while maintaining polished surface integrity. Construction industry applications include processing 16mm structural steel with bevel cutting capabilities up to 45 degrees for welding preparation. Modern systems incorporate real-time process monitoring through plasma emission detection and automatic parameter adjustment based on material surface condition analysis. The operational architecture includes centralized cooling systems with precision temperature control within ±0.2°C and multi-stage water filtration ensuring optical protection. Advanced software platforms provide simulation capabilities for cutting path optimization and thermal deformation prediction. The environmental benefits include 70% reduction in carbon footprint compared to traditional cutting methods and complete elimination of hazardous chemical consumption. For detailed technical specifications and application feasibility studies, please contact our engineering department for professional consultation and sample processing services.