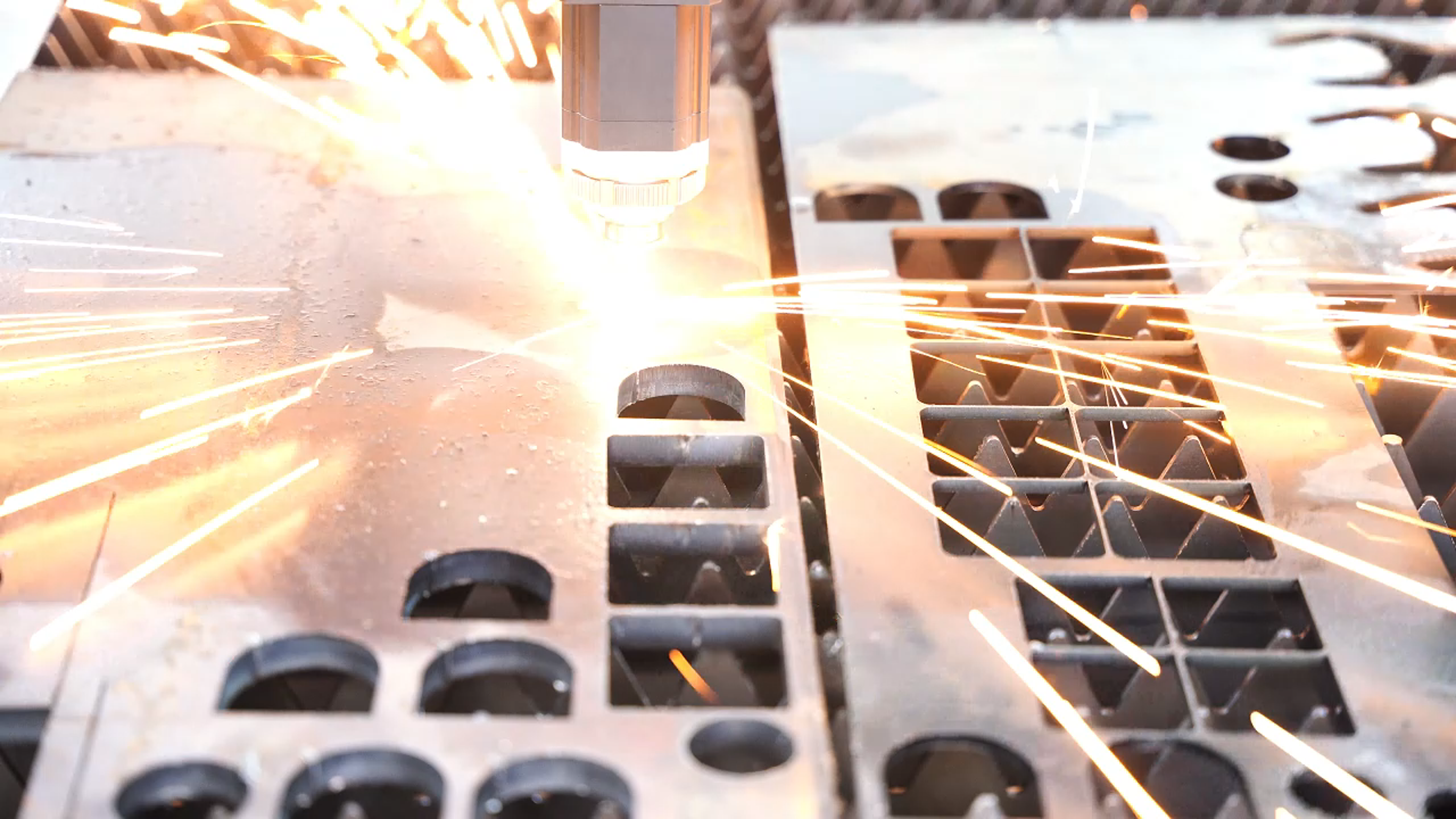

The operational excellence of fiber laser cutting systems stems from their solid-state design that eliminates complex gas flow systems and optical mirror alignment requirements. These systems generate laser radiation through ytterbium-doped optical fibers optically pumped by high-efficiency laser diodes, achieving wall-plug efficiencies of 35-40% with power output stability within ±1% over 10,000 hours. The beam delivery system employs flexible optical fibers with numerical apertures of 0.12-0.22, transmitting laser power to cutting heads with minimal energy loss. The cutting process involves precisely controlled thermal input where focused laser energy creates keyholes in materials, while coaxial assist gases (oxygen for carbon steel, nitrogen for stainless steel, compressed air for non-ferrous metals) eject molten material from the cut kerf. Modern cutting heads incorporate protective quartz windows with automated contamination monitoring and nozzle designs optimized for specific material thickness ranges. Industrial applications in agricultural machinery demonstrate processing of 10mm HARDOX steel at 2.5m/min with 8kW systems, achieving edge hardness preservation above 95% of base material. The technology shows remarkable precision in electronics enclosure production, where 4kW lasers cut 1.5mm aluminum at 25m/min with heat-affected zones controlled under 20μm. For food processing equipment fabrication, fiber lasers process 3mm polished stainless steel at 15m/min while maintaining corrosion resistance through dross-free cutting edges. Automotive industry applications include precision cutting of 2mm advanced high-strength steel with cutting speeds of 20m/min and dimensional accuracy of ±0.1mm. Advanced systems feature automatic material thickness detection through capacitive sensing and real-time cutting parameter adjustment based on material surface condition. The operational framework includes predictive maintenance systems monitoring diode pump degradation and fiber connector wear, typically providing maintenance intervals of 20,000 operating hours. Modern installations incorporate Industry 4.0 connectivity with real-time production data integration to factory management systems. The environmental advantages include 60% reduction in energy consumption compared to CO2 lasers and elimination of laser gas requirements. For detailed technical specifications and application-specific process validation, please contact our engineering team for professional consultation and equipment demonstration.